Device and operating method for preventing silicon wafer from offset and cracking in cavity transporting process

An operation method and cavity technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of position deviation when the robot arm takes the wafer, and it is impossible to detect whether the silicon wafer has shifted or not. Problems such as wafer offset and tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable your examiners to have a further understanding and understanding of the purpose, features and effects of the present invention, the following detailed description is as follows with the accompanying drawings.

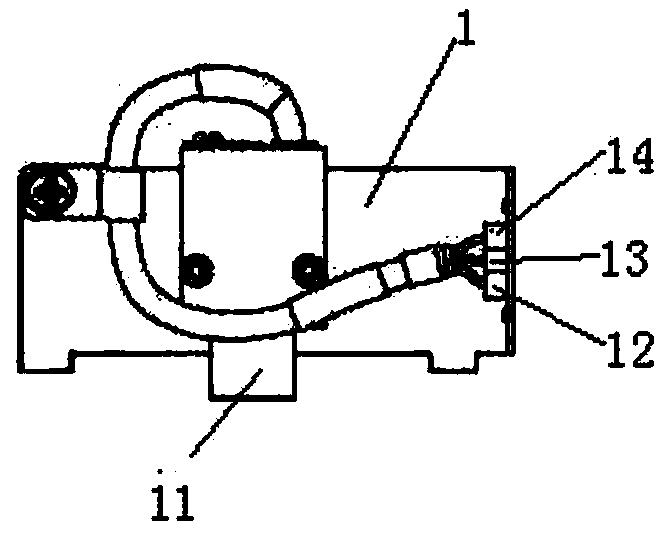

[0027] like figure 1 Shown, be the structure of the photoelectric sensor used in the present invention, comprise measuring port 11 and three interfaces in the photoelectric sensor 1, described three interfaces are respectively photoelectric sensor positive input end 12, photoelectric sensor negative input end 13 and photoelectric sensor Sensor signal terminal 14.

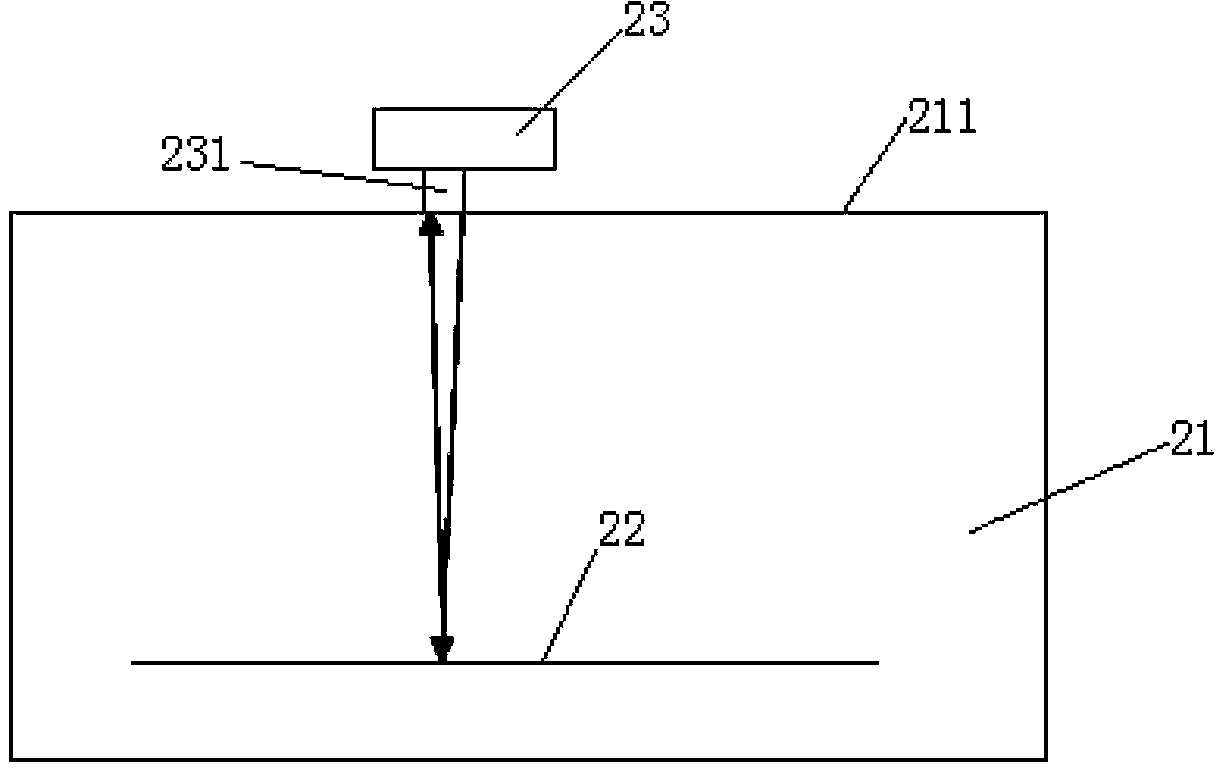

[0028] like figure 2 As shown, it is a schematic diagram of the position measurement of the photoelectric sensor of the present invention. A light beam is emitted from the measurement port 231 of the photoelectric sensor 23 to the surface of the silicon wafer 22 to be measured, and the measurement port 231 is emitted from the surface of the silicon wafer 22, thereby measuring the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com