Built-in axial flow roller driving device

A drive device, built-in technology, used in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of troublesome maintenance and can only be installed at the rear of the axial flow drum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

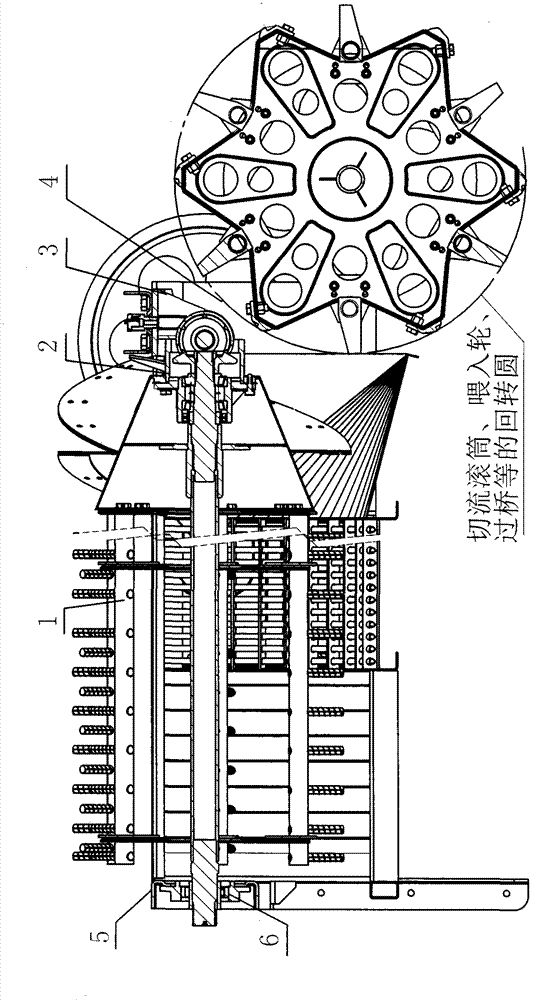

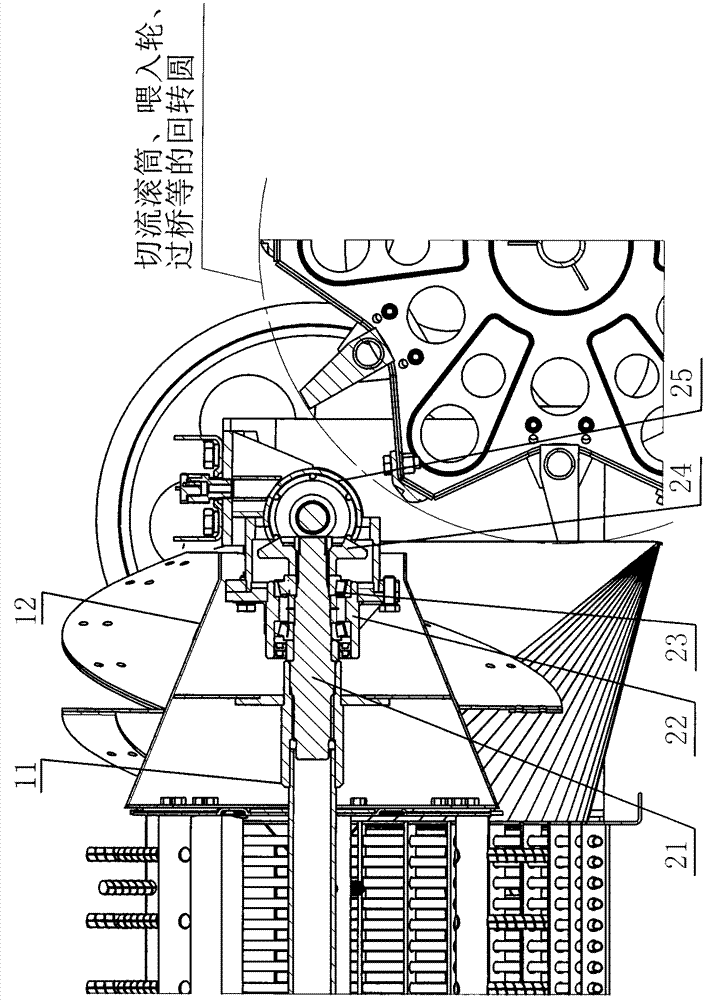

[0014] The present invention is a built-in axial flow roller driving device, which is mainly composed of an axial flow roller 1, a drive box 2, a front beam 3 and an axial flow frame 4, etc. The specific implementation method is as follows:

[0015] 1. The driving box 2 is hoisted on the front end of the axial flow frame 4 through the front beam 3. The front end of the central axis 11 of the axial flow drum 1 is indented into the leading cone 12 for a certain distance, leaving a cavity for the front end of the leading cone 12. When installing, the axial flow The front end of the central axis of the drum 1 is installed on the output shaft 21 of the driving box 2, and the power is supported and transmitted through the output shaft 21. At this time, the second half of the driving box 2 is just in the cavity of the leading cone 12 at the front end of the flow drum 1. The rear end of flow drum 1 is then supported by rear beam 5 and bearing 6 (see figure 1 and figure 2 ).

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com