Wind-and-rain-prevention down jacket and manufacturing method of wind-and-rain-prevention down jacket

A production method and technology for down jackets are applied in the field of down jackets, which can solve the problems of being heavy, troublesome to wear, and have no appearance effect of down jackets, and achieve the effects of improving warmth retention, improving waterproofness, and having a three-dimensional appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the purpose, structure and function of the present invention, the weatherproof down jacket of the present invention and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings.

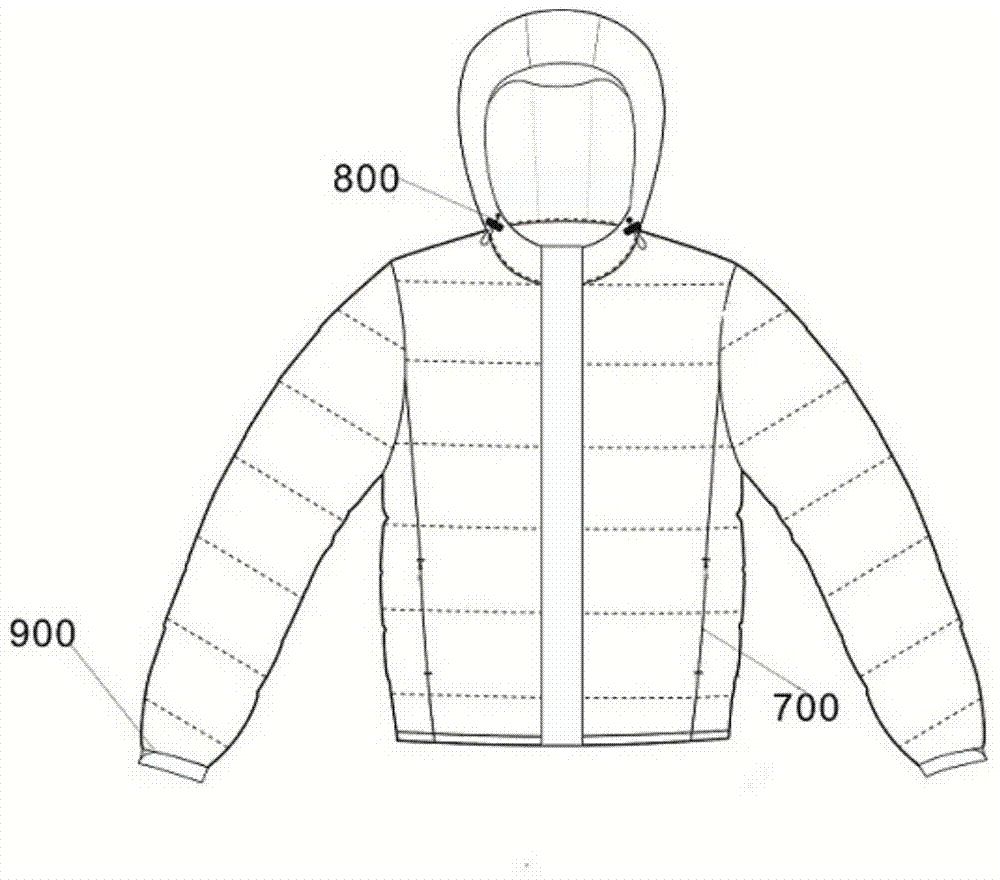

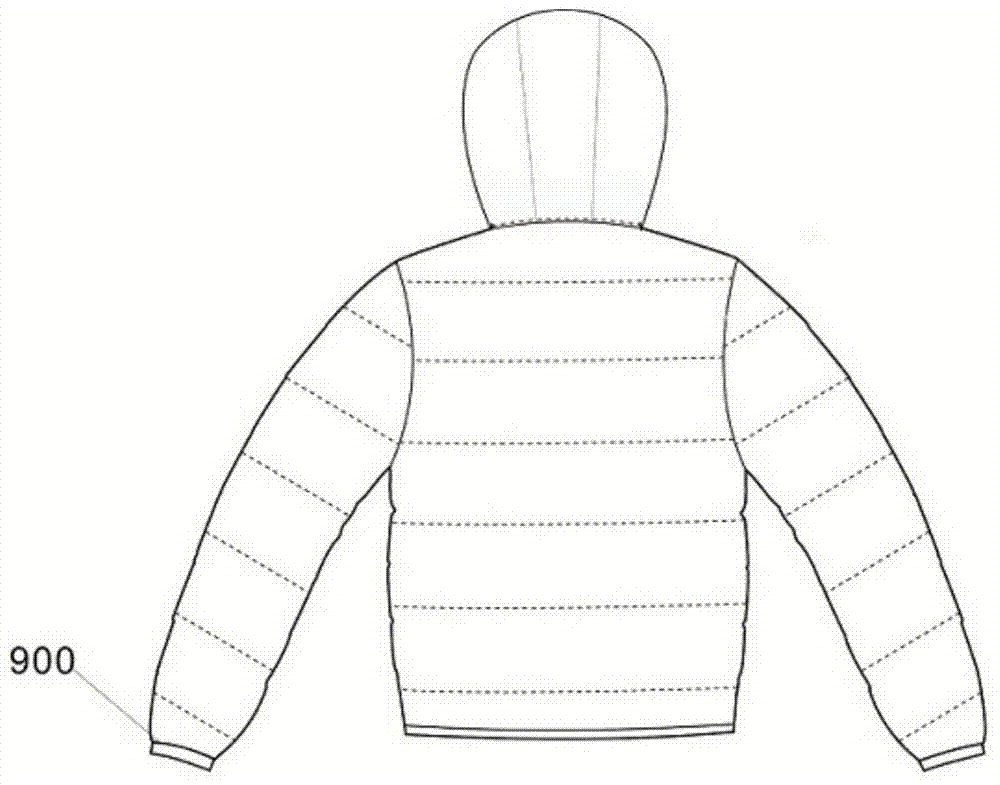

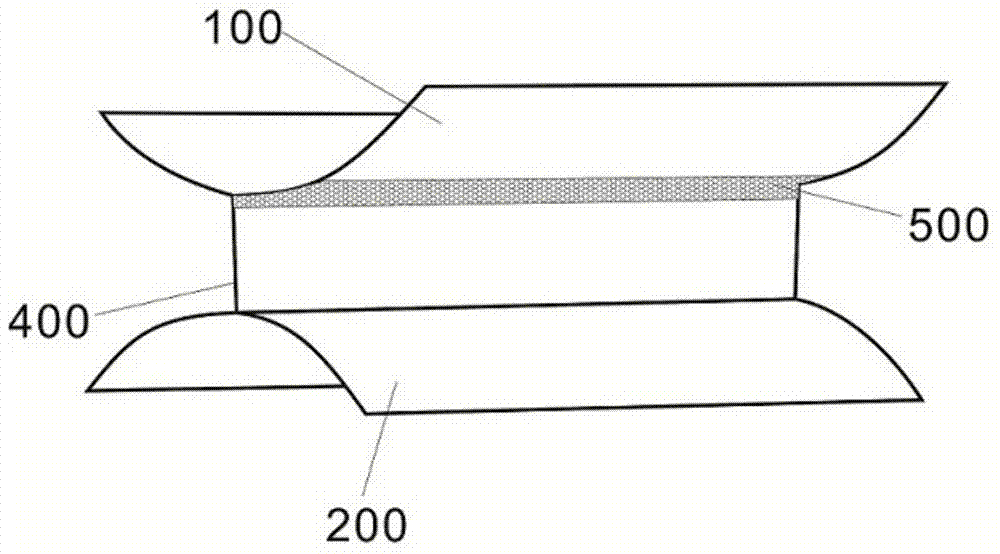

[0030] Such as Figure 1 to Figure 10 As shown, the weatherproof down jacket of the present invention includes a layered surface layer 100, a bile layer 200 and an inner layer 300, wherein a plurality of spacers 400 are arranged laterally between the surface layer 100 and the bile layer 200, and the surface layer 100, the bile layer A filling cavity for filling down products is formed between the 200 and the spacer 400 . In addition, the weatherproof down jacket of the present invention is also provided with waterproof strips 500 at the seams, thereby increasing the waterproof and windproof performance of the down jacket and the warmth retention at the in-line, thereby achieving the purpose of improving heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap