Universal exhaust hood used in laboratory

A laboratory, exhaust hood technology, applied in the directions of cleaning methods and utensils, removing smoke and dust, chemical instruments and methods, etc., can solve the problems such as the inability to adjust the exhaust hood, the inability to rotate and adjust the air collecting hood, and the inconvenience. To achieve the effect of improving the flexibility and adaptability of use, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings of the embodiments.

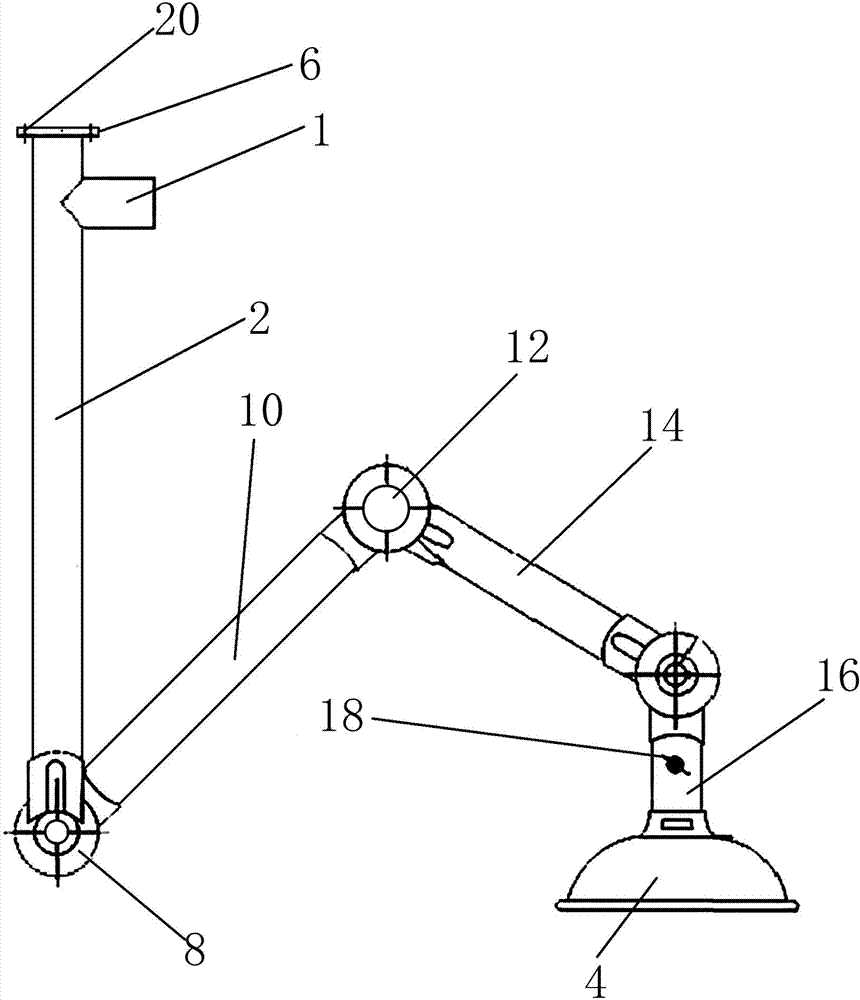

[0014] Such as figure 1 As shown, a universal exhaust hood for a laboratory includes a longitudinal air duct 2 with an air outlet 1 and an open air collection hood 4, and one end of the air duct 2 is provided with a mounting bracket 6, Its other end communicates with the wind collecting hood 4 through a connection device, and the connection device has a transfer pipe 8, a first connection pipe 10, a bearing pipe 12, and a second connection pipe 14 connected in sequence, and one end of the second connection pipe 14 is connected to The wind collecting hood 4 is butted and communicated, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com