A rack type automatic material transfer lamination machine

A laminator and rack-type technology, which is applied in the field of rack-type automatic material transfer laminator, can solve problems such as threats to workers' life safety, and achieve the effects of saving labor, reducing costs, and promoting standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

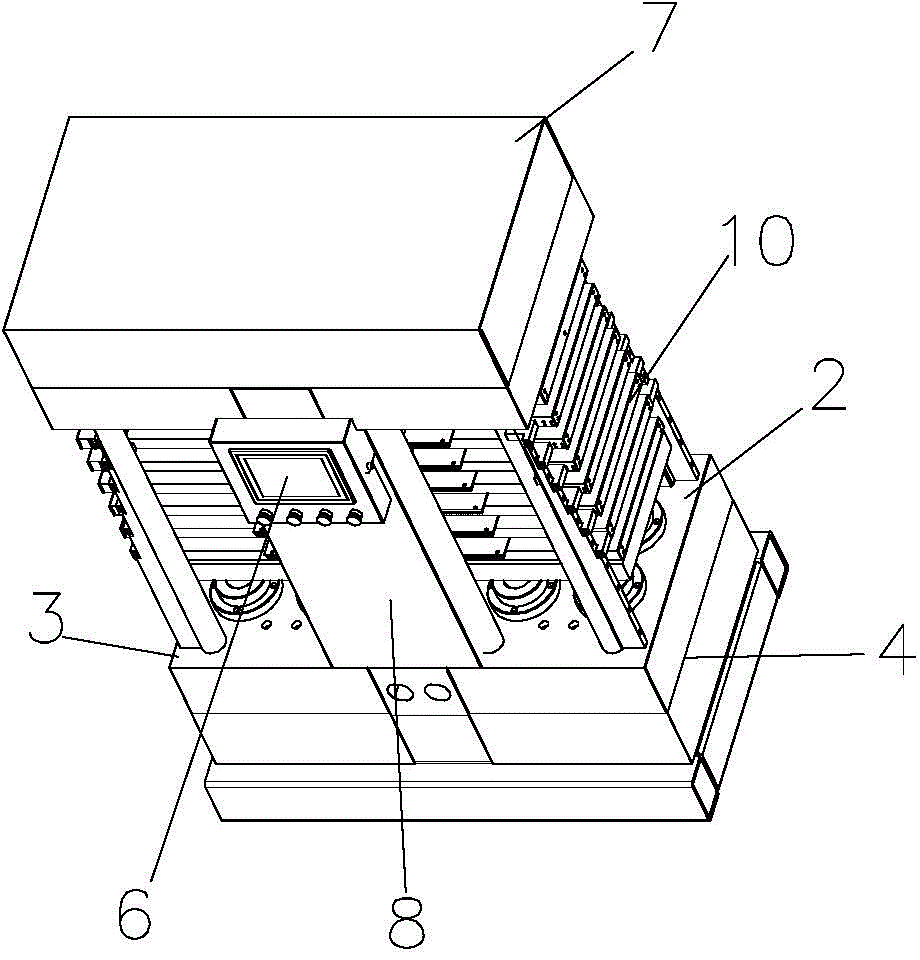

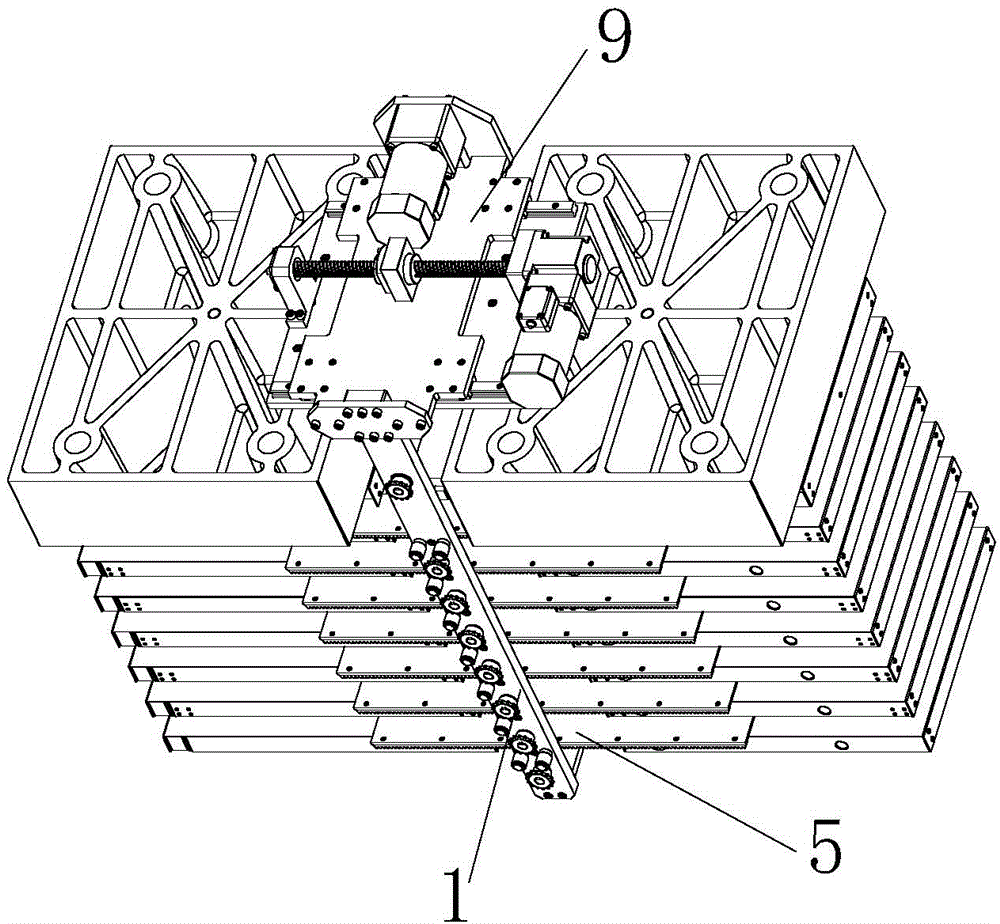

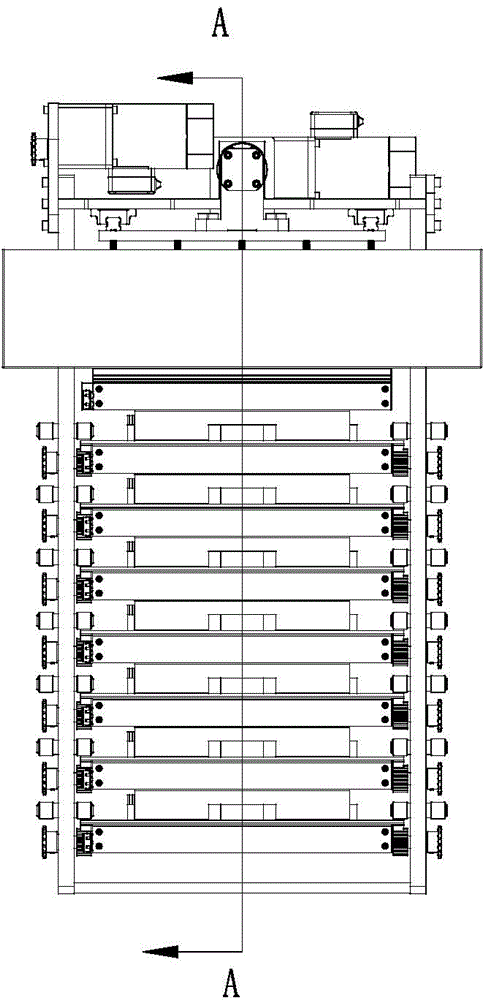

[0027] Such as Figure 1-Figure 9 As shown, the rack type automatic material transfer laminator of the present invention includes a hot lamination tower 2, a cold lamination tower 3 and an automatic material transfer device.

[0028] The hot lamination tower 2 and the cold lamination tower 3 comprise a riser 8 , a plurality of lamination plates 10 and a drive 4 . The hot lamination tower 2 and the cold lamination tower 3 are placed side by side, and the discharge position of the hot lamination tower 2 faces the feed position of the cold lamination tower 3 . The driving device 4 drives the laminated board 10 to lift up and down, which is realized by a hydraulic lifting system in this embodiment. A tray 5 is placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com