A parallel inflow control box and a parallel inflow control device

An inflow control, parallel technology, used in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of complex structure and poor applicability of adaptive inflow control devices, achieve flow suppression, ensure long-term The effect of stable production and increased flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

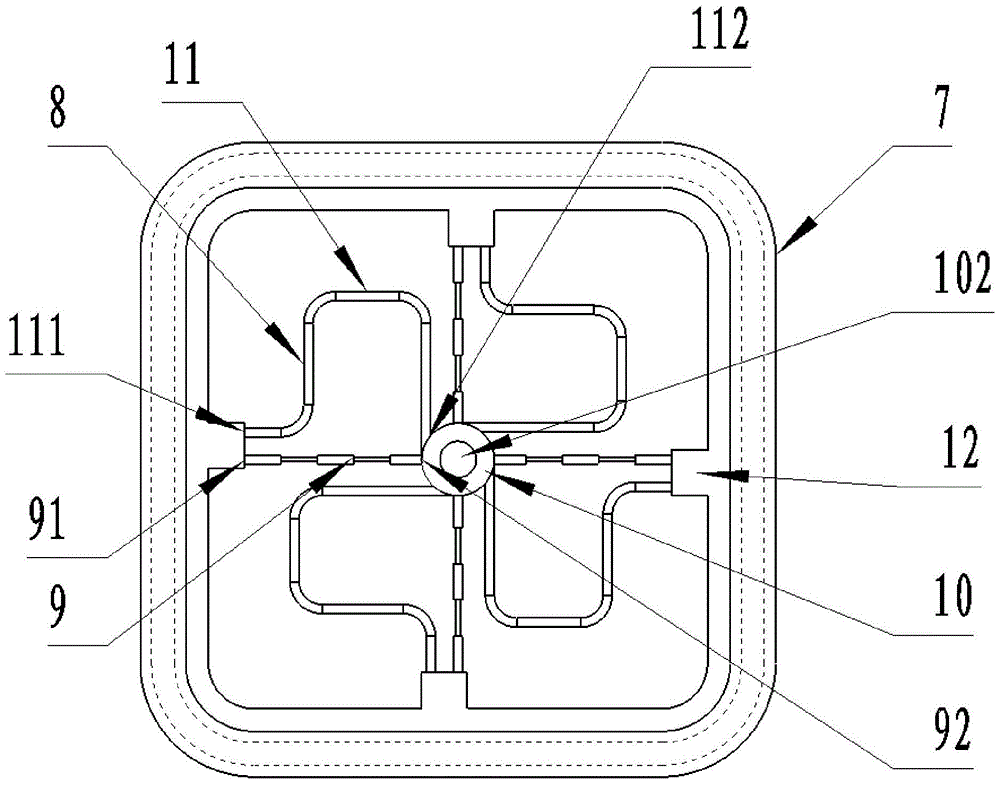

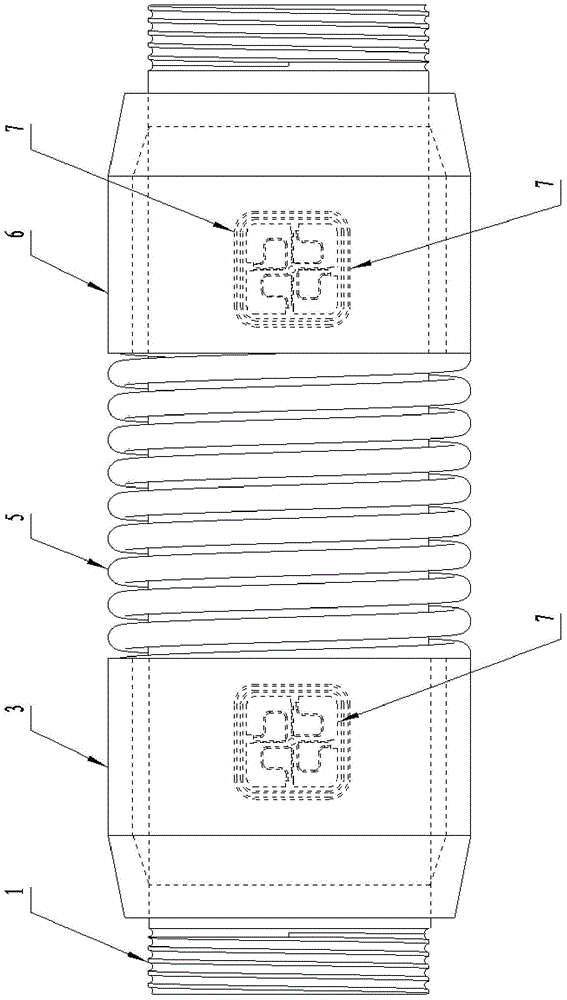

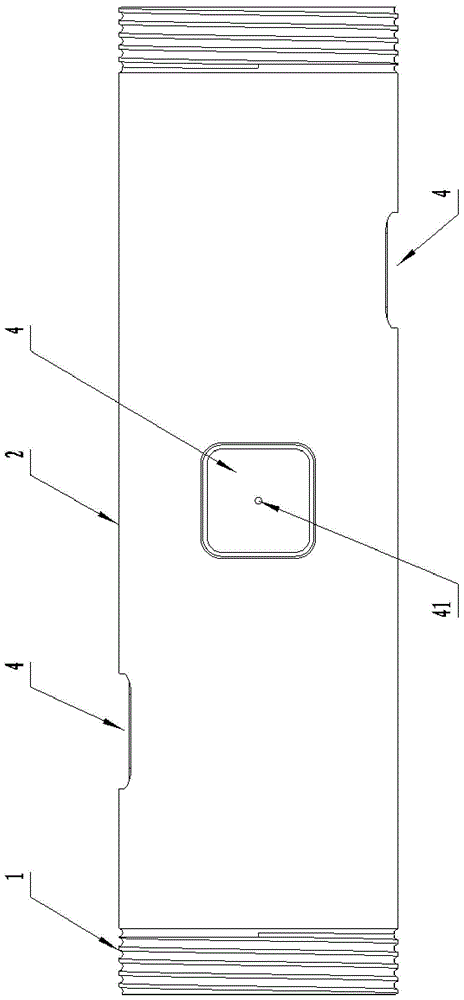

[0021] The parallel inflow control box of the present invention will be further described in detail below in conjunction with the accompanying drawings. A parallel inflow control box, including a parallel flow divider 8 and a hollow flow restrictor 10; the parallel flow divider 8 contains a flow limiting pipeline 9 and a friction pipeline 11, and the flow limiting pipeline 9 expands the flow area The pipelines arranged alternately by contraction, the frictional resistance pipeline 11 is a curved pipeline, the outlet 92 of the flow limiting pipeline and the outlet 112 of the frictional resistance pipeline are all connected with the flow limiter 10, and the parallel flow control box 7 is provided with a When the liquid enters the diversion channel 12 inside the parallel inflow control box 7, the inlet 91 of the flow limiting pipeline and the inlet 11 of the friction pipeline are both connected with the diversion channel 12 of the parallel inflow control box 7, and the parallel in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com