Fireproof check valve of automatic falling valve plate

A technology for automatic drop and check valves, applied to the parts in contact between valve elements and valve seats, lift valves, valve details, etc., can solve the problems of reduced elastic performance, incomplete valve closure, and affecting the sealing effect of the valve. Achieve the effect of improving service life and simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

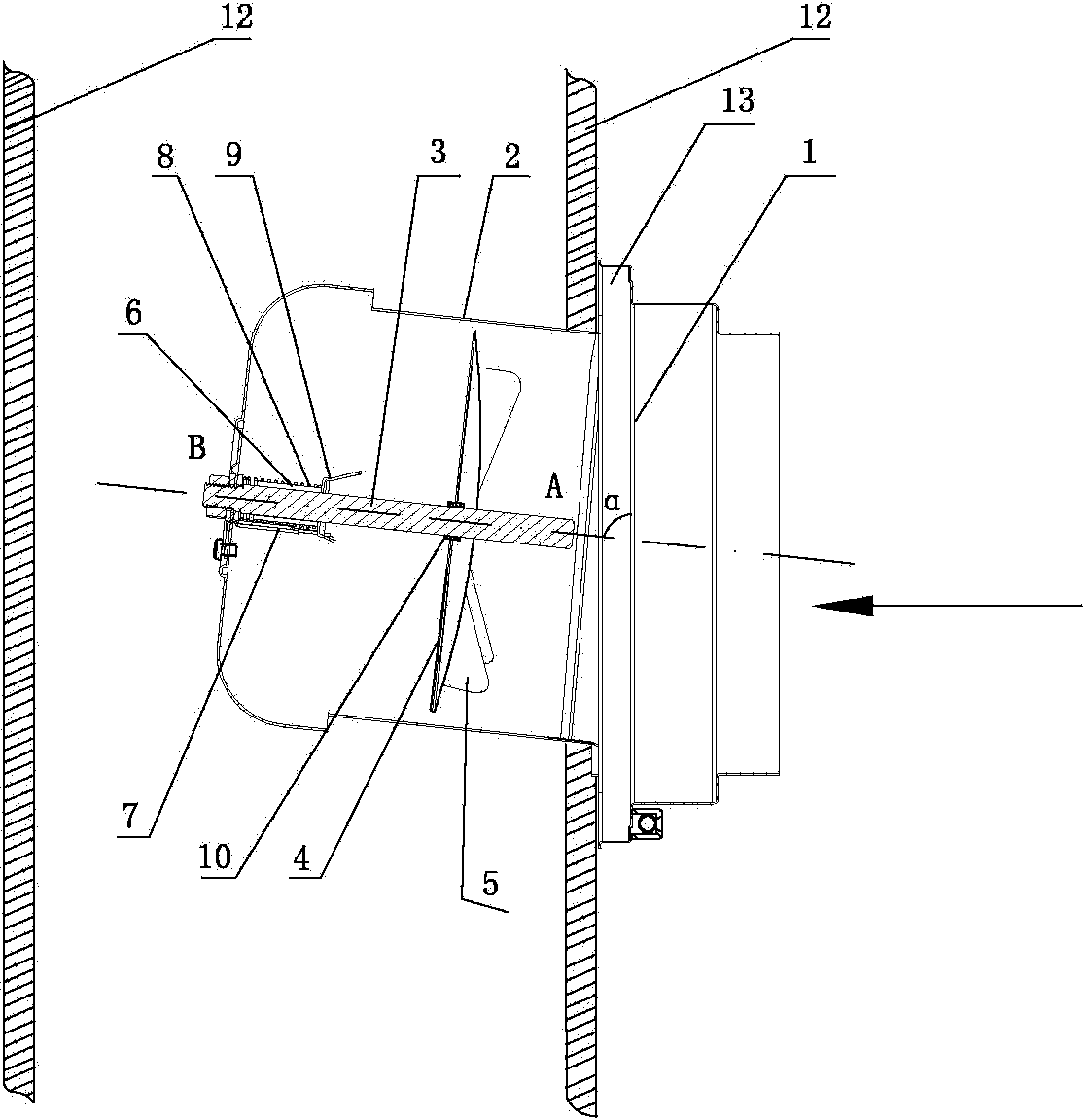

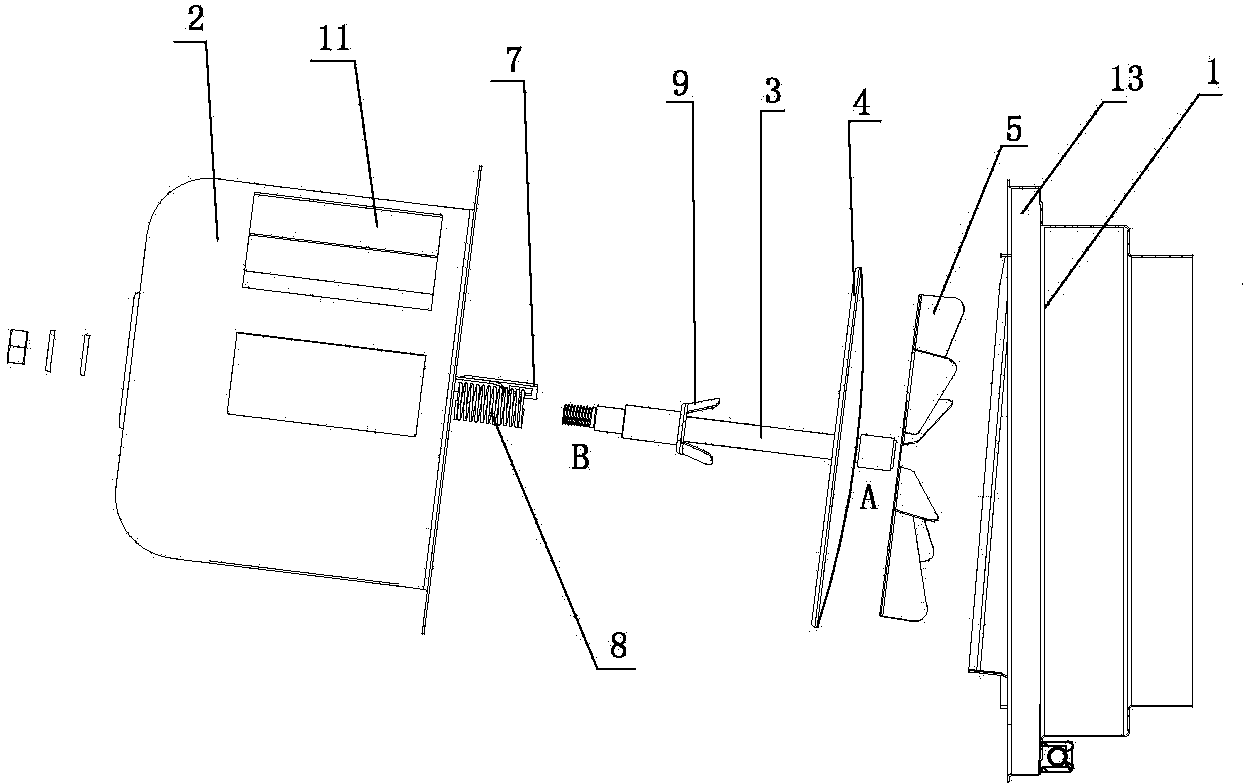

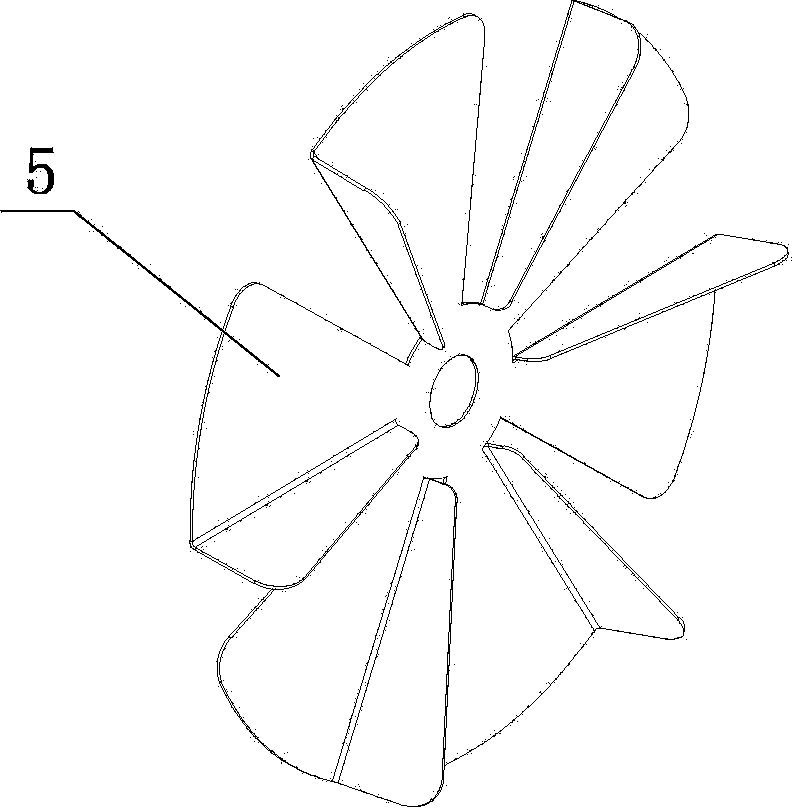

[0021] Such as figure 1 As shown, the present invention includes a check valve seat 1, a check valve seat panel 13 parallel to the flue pipe wall 12 is arranged on the check valve seat, and the front portion of the check valve seat 1 (i.e. figure 1 The right direction in the center) is provided with the hose interface of the range hood, and the short diversion pipe 2 is installed at the rear of the check valve seat 1. When the valve is installed on the oil fume exhaust pipe 12, the check valve seat panel 13 is parallel to the pipe wall 12 of the vertical oil fume exhaust pipe. A guide shaft 3 is installed in the guide short pipe 2, and the front end of the guide shaft 3 (i.e. figure 1 , 2 The end A in the center) is inclined downward, and the included angle α with the check valve seat panel 13 is 30°~85°. The rear end of guide shaft 3 (i.e. figure 1 , 2 The end B in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com