Inductive building separated solar water heater and operating controlling method

A solar water heater and building-type technology, applied in solar thermal power generation, solar thermal installations, sustainable buildings, etc., can solve the problems of affecting the architectural shape, inability to meet, inconvenient use, etc., to achieve improved thermal energy utilization, reasonable structural design, Easy to use and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

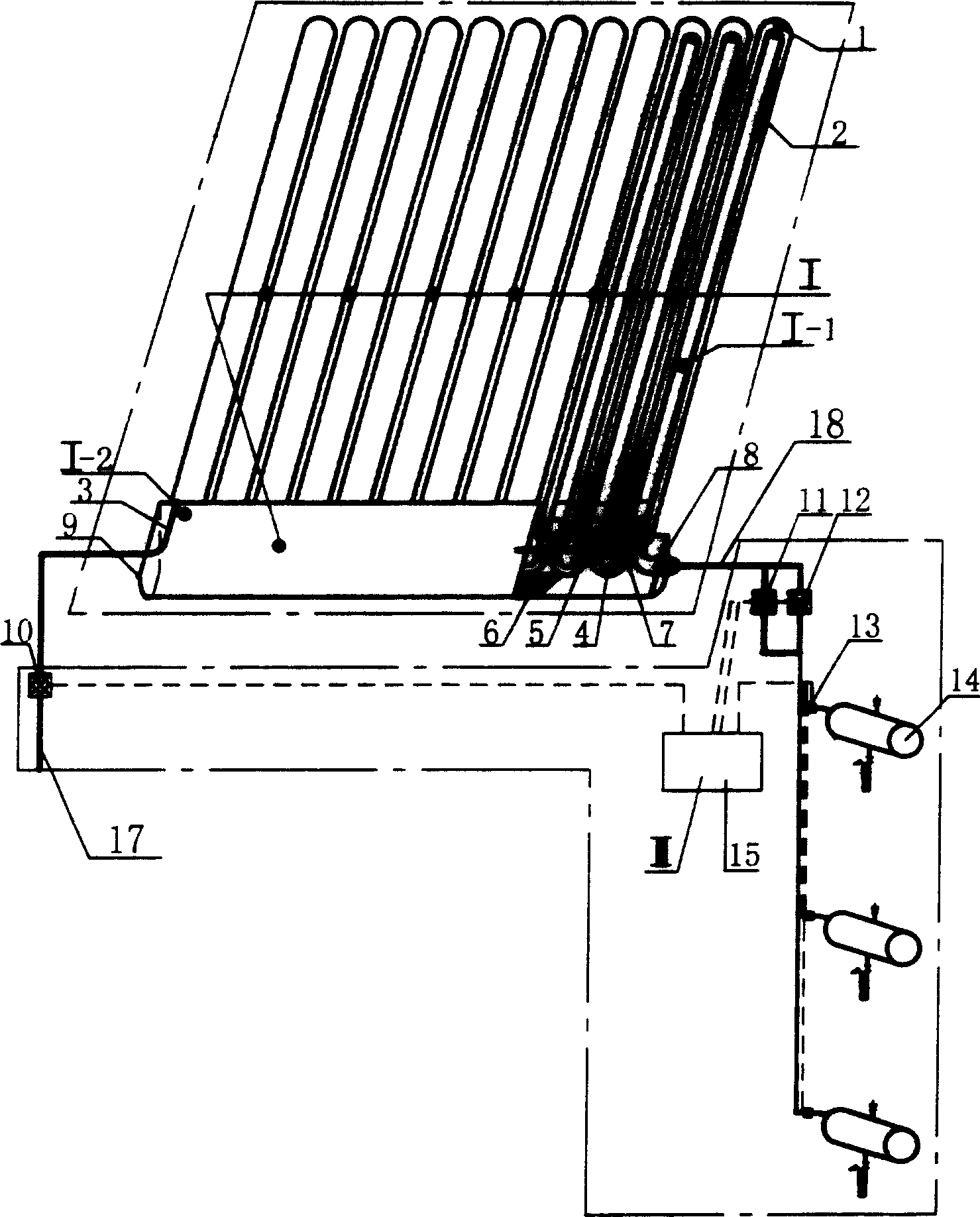

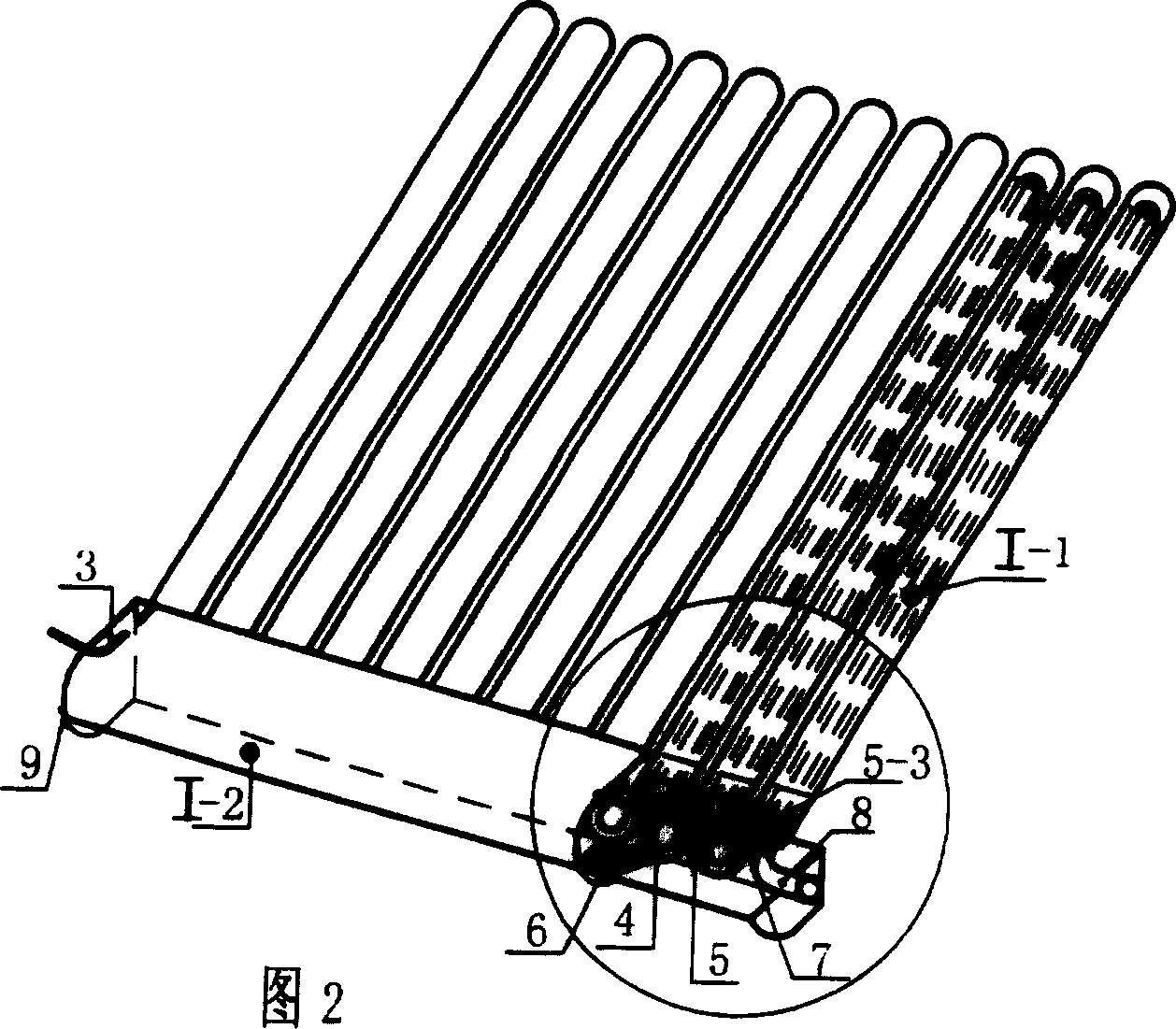

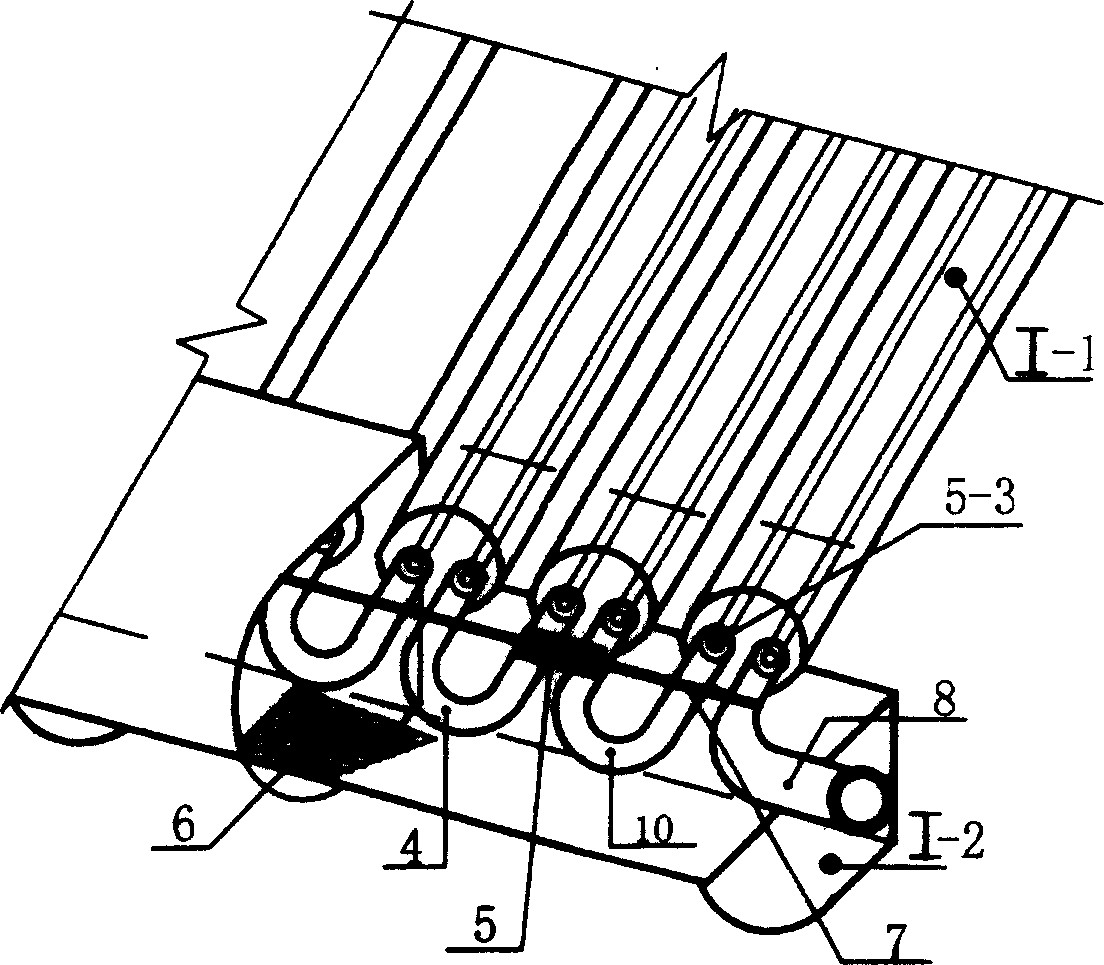

[0026] see figure 1 - Fig. 5, the present invention mainly is made up of heat collecting tube device I, water storage tank 14 and control part III, and heat collecting tube device I comprises heat collecting tube part I-1 and induction tube part I-2, and heat collecting tube part I-1 is made of glass tube 1 and heat collecting tube 2, the shape of heat collecting tube 2 is U-shaped; induction tube part I-2 includes induction tube 4, outer cover 9 with insulation layer 6, connector 7, induction inlet and outlet pipes 3, 8, induction tube 4 It is a U-shaped tube, which is plugged with the heat collecting pipe 2, and the induction pipe 4 is also bonded with the connecting body 7, and the connecting body 7 is bonded with a thermal sensor 5, and the induced water inlet and outlet pipes 3, 8 are also connected with the heat collecting pipe 2. Docking. The control part III includes a computer control device 15, an inlet water flow regulating valve 10, an outlet water temperature con...

Embodiment 2

[0032] see Figure 7-8 , which is a structural schematic diagram of the application of the present invention in engineering. Said engineering refers to the installation area of more than 100 square meters, and when the required water consumption is greater than 1 liter / second, the diameter of the induction tube requires a solar thermal energy of greater than 25 mm. Water system, wherein, the induction pipe in the induction pipe part I-2 is a continuous induction pipe 16, and the rest are the same as the system example 1.

[0033] See Figure 5, Figure 9 , the present invention makes the cold medium water enter the heat collecting tube device 1 by way of induction, and heat energy exchange is performed in the heat collecting tube device 1, while hot water then flows out from the water outlet 8. That is: first, the whole is in a closed state, and when the roof heat collecting tube device 1 absorbs heat, the temperature rises, and the signal is sent to the indoor computer cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com