Automatic lubrication system of filter press

A technology of automatic lubrication and lubrication system, applied in the direction of engine lubrication, mechanical equipment, engine components, etc., can solve the problems of inaccurate time of manual lubrication, difficulty in guaranteeing lubrication cycle and quality, and shortening the service life of filter presses. The effect of reducing mechanical maintenance costs, operating safety, and reducing mechanical wear and failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

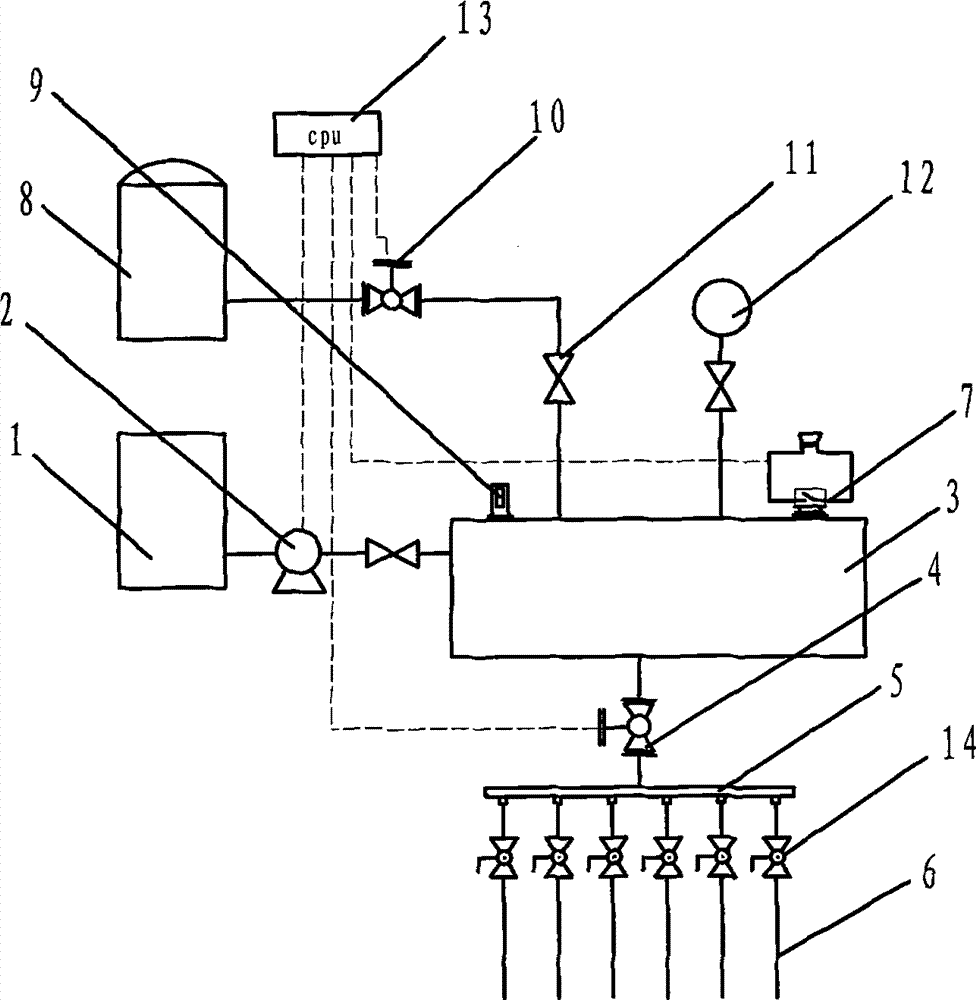

[0012] see figure 1 As shown, the present invention provides a kind of automatic lubricating system of filter press, and this system is provided with oil tank body 3 and is installed on the filter press machine base, and oil tank body 3 is designed and manufactured according to pressure vessel, and the working pressure of design is 1.0PMa, and oil tank body 3 The check valve 11 is installed on the welding pipeline to connect with the oil delivery pump 2, the oil delivery pump 2 is connected to the oil storage tank 1 through the pipeline, the PLC programmable controller 13 is installed in the electric control cabinet of the filter press, and the check valve is installed on the welding pipeline on the oil tank body 3 11 Connect the gas source solenoid valve 10 to the gas storage tank 8, the gas storage tank 8 is designed and manufactured as a pressure vessel, the designed working pressure is 1.0 PMa, the oil pipeline is welded under the oil tank body 3, and the oil pipeline is in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap