Testing device of oxygen/iodine ultrasonic mixing heat flow field

A testing device, supersonic technology, used in measuring devices, material analysis through optical means, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

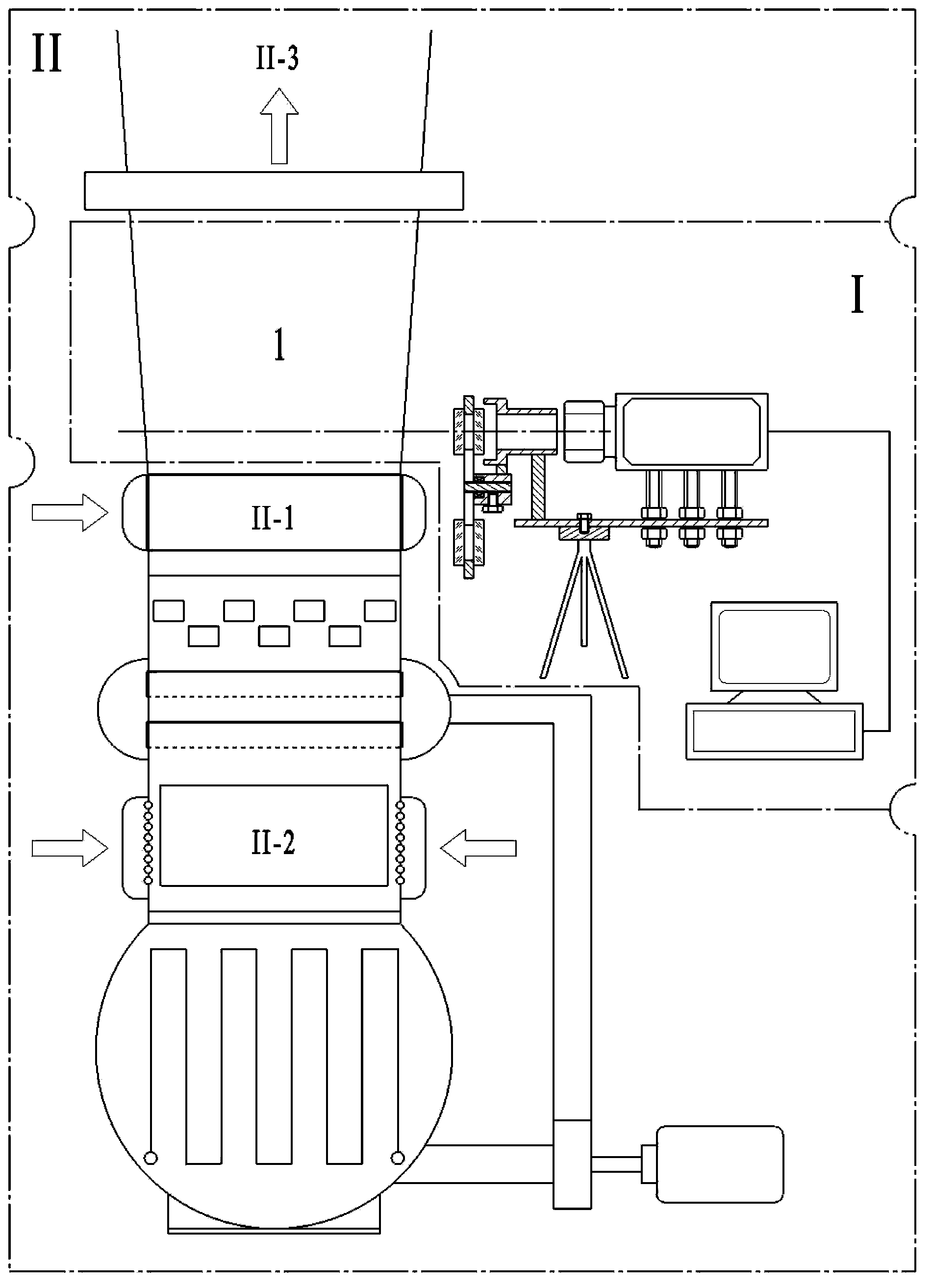

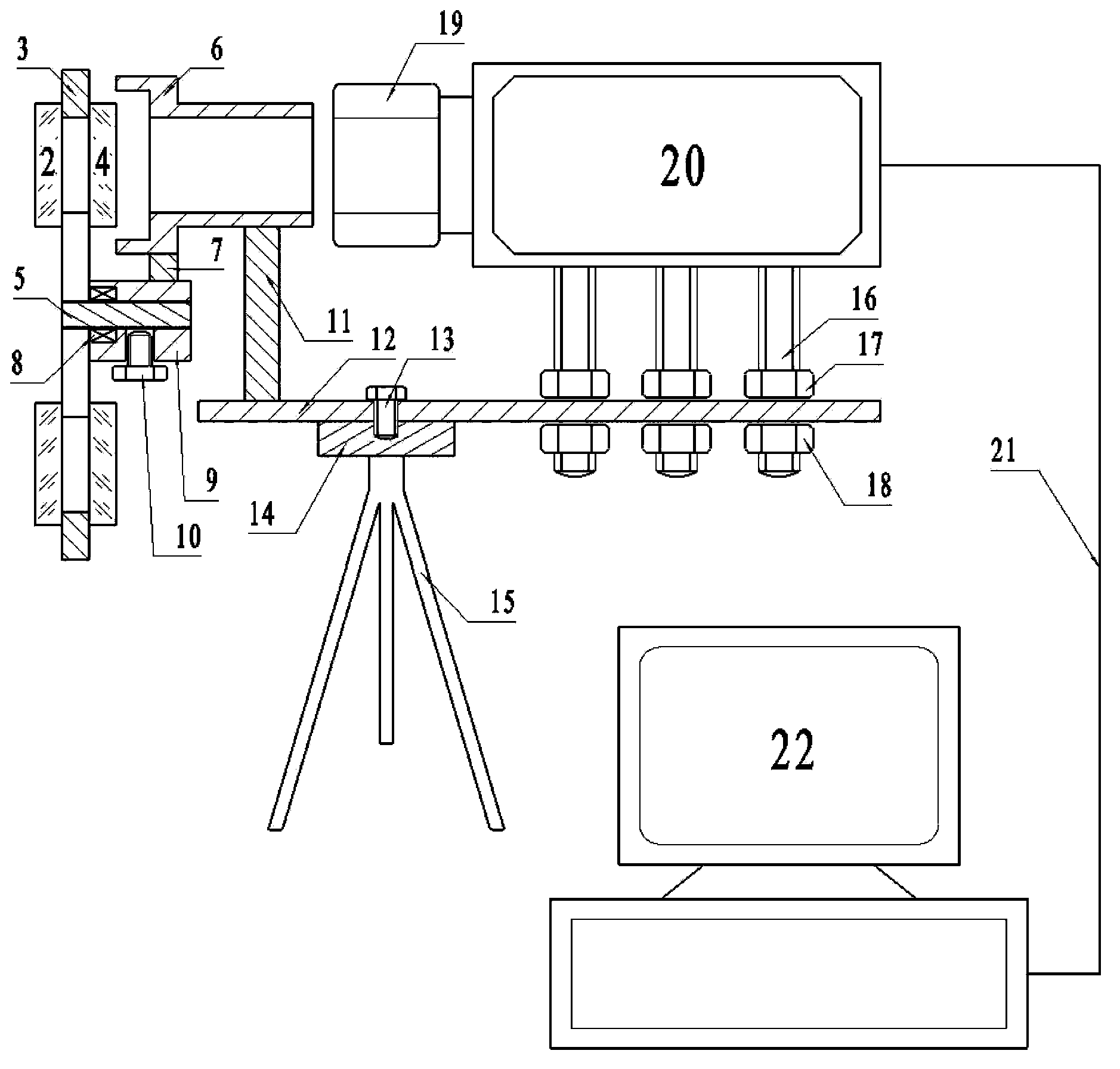

[0042] A test device for oxygen / iodine supersonic mixed heat flow field, characterized in that it includes: test section 1; optical filter 2; rotating disc 3; attenuation plate 4; rotating shaft 5; ; Bearing 8; fixed shaft 9; set screw 10; 2# connecting plate 11; fixed plate 12; fixed screw 13; tripod head 14; tripod 15; ; High-speed CCD camera 20; Data cable 21; Computer data acquisition and processing system 22;

[0043] Test section 1 is connected to the oxygen iodine chemical laser II, located above the nozzle module figure 1 .

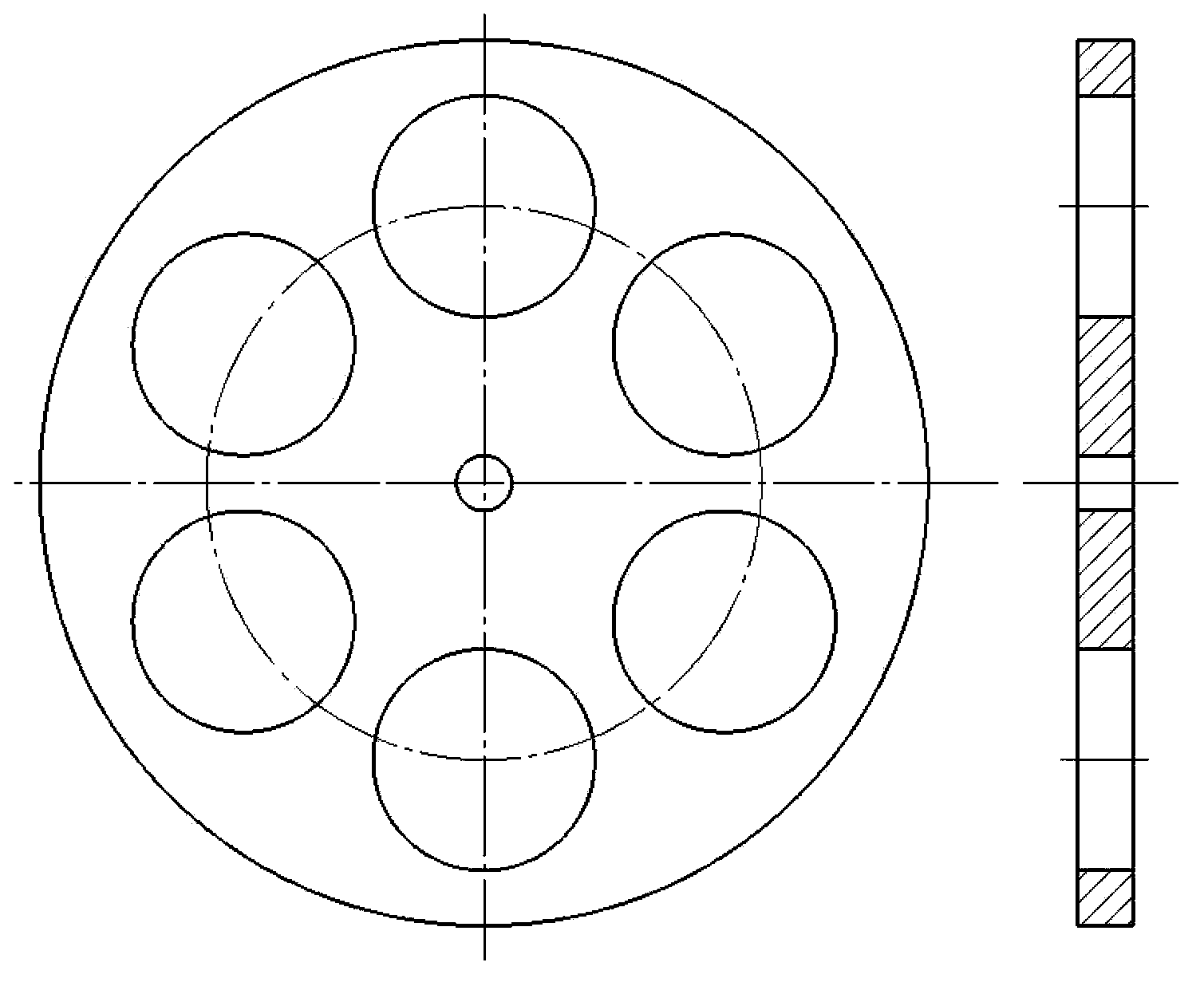

[0044] turntable 3 image 3 There are 6 Ф40 through holes along its circumference, and 1 Ф10 through hole in the middle. A filter 2 and an attenuation sheet 4 are attached to both sides of each Ф40 through hole.

[0045] Rotating shaft 5 is a straight rod, and one end is inserted in the through hole of rotating disk 3 circle centers, and is welded with it.

[0046] Fixed shaft 9 is a cylinder, and its front end is inlaid with bearing 8. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com