A paper making machine for making tissue paper and a method of operating a paper making machine

A technology of paper machine and thin paper, applied in the field of paper machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

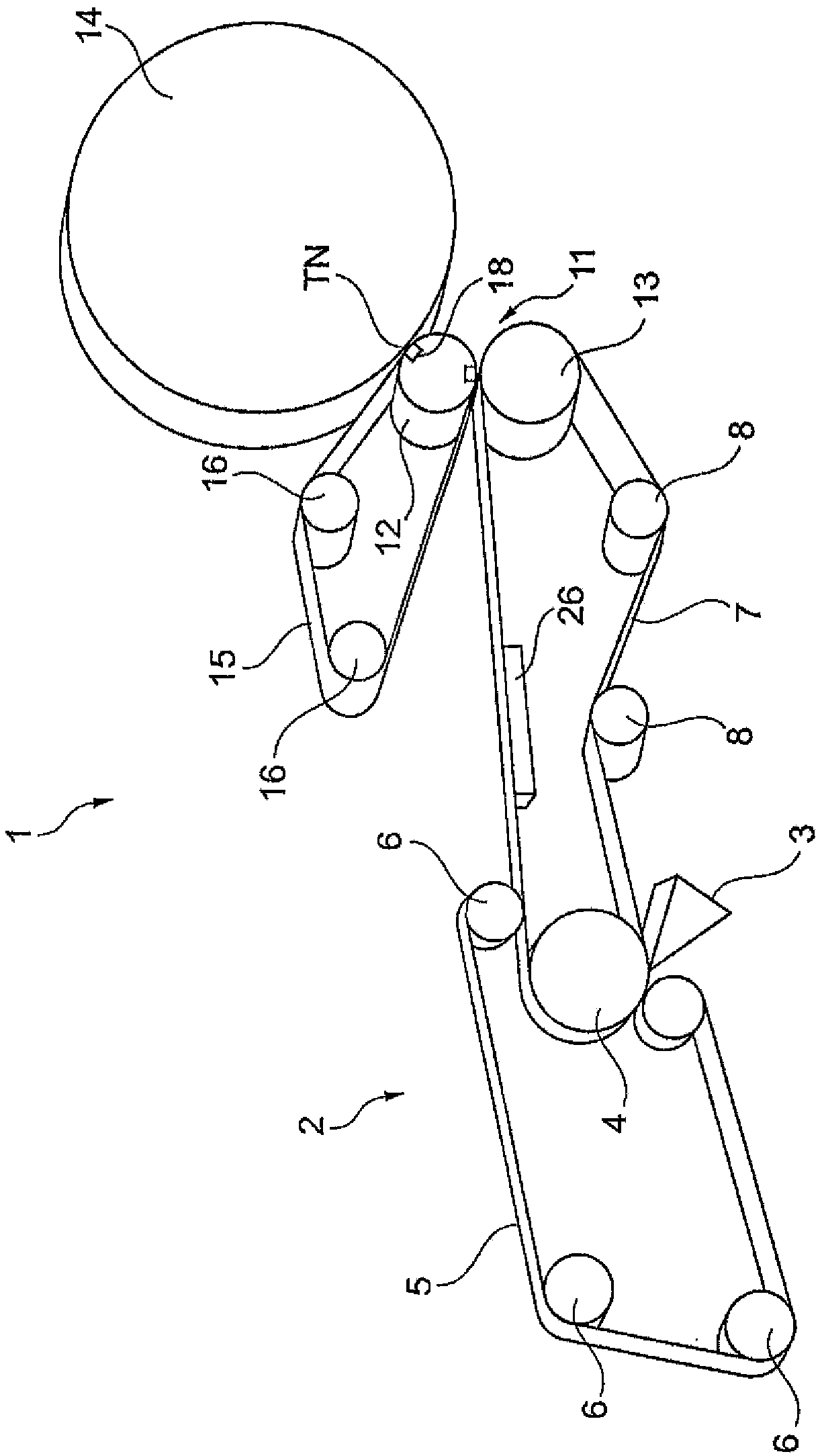

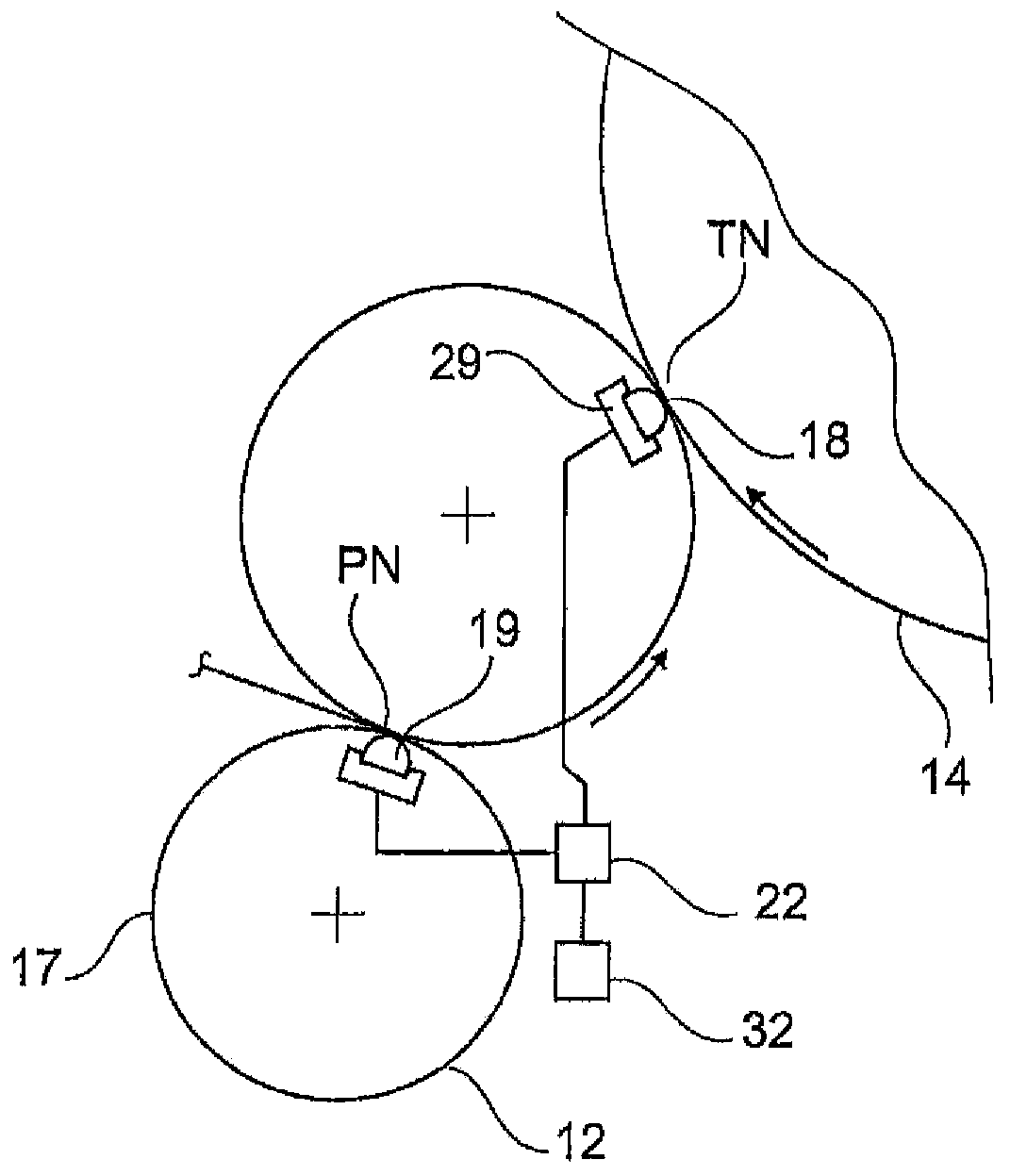

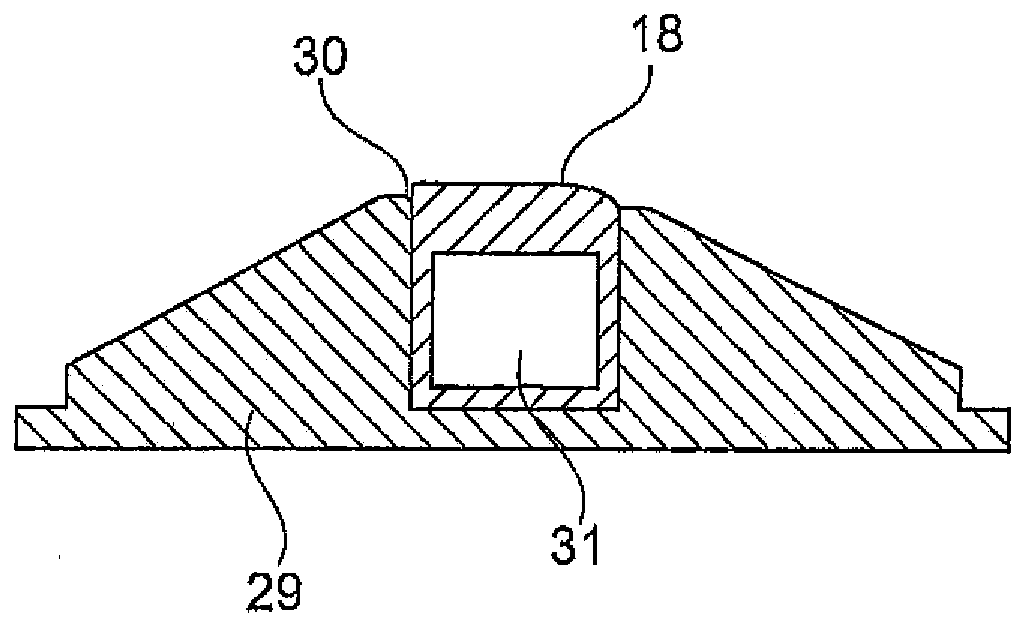

[0038] refer to figure 1, the invention relates to a paper machine 1 for the manufacture of paper, especially tissue paper. As used herein, the term "thin paper" refers to paper having a relatively low basis weight. In most cases this means a basis weight of 10g / m 2 up to 50g / m 2 Examples of tissue paper webs in which the basis weight may lie outside this range are known. Unlike cardboard, tissue paper does not have to be rigid, and thus tissue paper can have a lower basis weight. In most cases, the basis weight of thin paper can be in the range of 15g / m 2 up to 40g / m 2 range, and typical values can be in the range of 15g / m 2 up to 30g / m 2 or 20g / m 2 up to 30g / m 2 In the range. Such paper can be used, for example, as facial tissue, toilet tissue or absorbent tissue (eg dish towels). The machine according to the invention comprises a former 2 in which a fibrous web can be formed. like figure 1 As can be seen in , the former 2 has a forming roll 4 , a forming fabr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap