Device for feeding after cutting pole pieces

A technology of pole pieces and cutting slots, which is applied in the field of equipment for feeding pole pieces after cutting, can solve the problems of reducing the cutting feeding speed, reducing the lamination speed, and inaccurate laminations, so as to ensure position accuracy and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

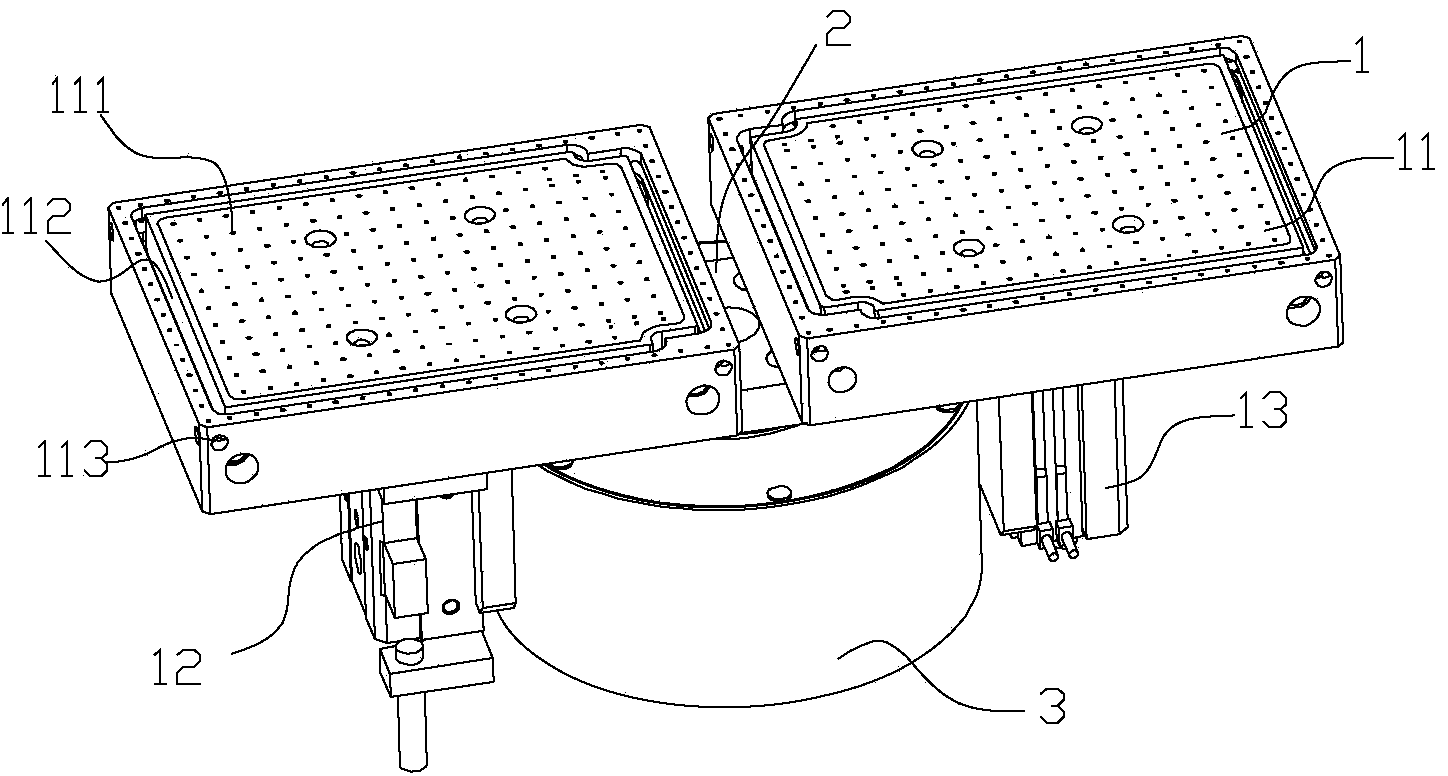

[0019] Such as figure 1 As shown, this embodiment provides a device for feeding pole pieces after cutting, and this embodiment preferably includes two adsorption mechanisms 1 , a rotary frame 2 and a rotary drive mechanism 3 .

[0020] The adsorption mechanism 1 includes a suction cup 11 and an adsorption driver 12. The suction cup 11 is a cuboid and is provided with a plane for placing the pole piece. The plane is provided with an adsorption hole 111 and a cutting groove 112. The cutting groove is square and consistent with the shape of the pole piece, that is, Laser cutting is to cut the pole piece along the cutting groove 112 . The adsorption hole 111 is arranged in the plane surrounded by the cutting groove 112 and on the edge plane outside the cutting groove 112. The adsorption hole 111 is connected with the adsorption driving part 12. When the pole piece is placed on the suction cup 11 for cutting, the adsorption driving part 12 is a vacuum. Adsorption cylinder, through...

Embodiment 2

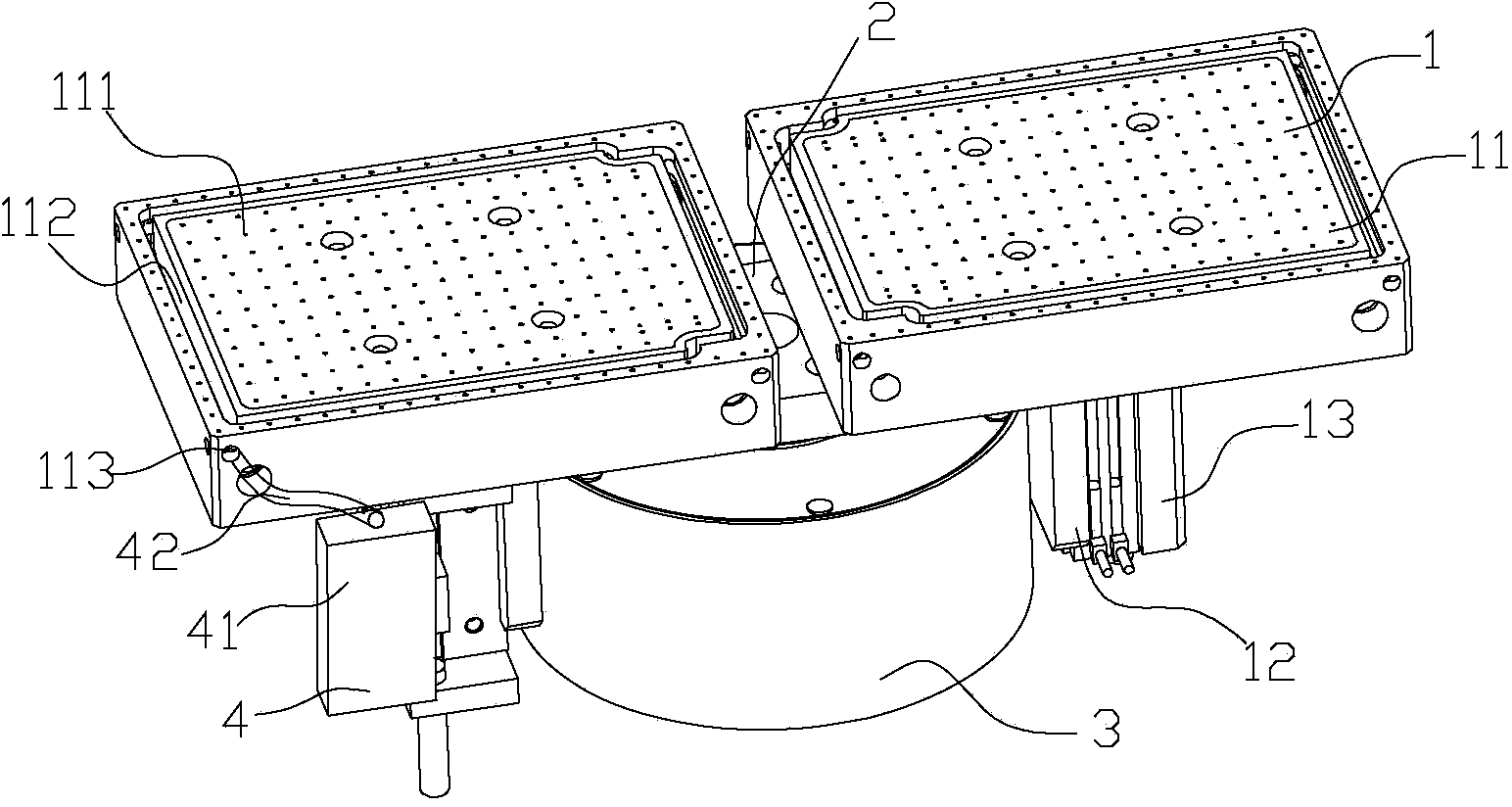

[0024] Such as figure 2 As shown, the difference between this embodiment and the above-mentioned embodiment is that a waste suction mechanism 4 is added on the basis of the above-mentioned embodiment, and the cutting groove 112 is provided with a through hole 113 .

[0025] The waste suction mechanism 4 includes a vacuum pump 41 and a suction pipe 42. The vacuum pump 41 is installed on the rotating frame 2. In other embodiments, it can also be directly installed on the suction cup 11. The outer wall of each corner in the cutting groove 112 is provided with a through hole 113. One end of the suction pipe 42 is connected to the vacuum pump 41, and the other end is connected to the through hole 113 in the cutting groove 112. When the pole piece is laser cut, dust will be generated and enter the cutting groove 112. The vacuum pump 41 of the waste suction mechanism 4 can be used during the process. During laser cutting, the dust in the cutting groove 112 is sucked and collected th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com