Flip screen printing device of battery packaging line

A screen printing device and storage battery technology, which is applied to rotary printing machines, screen printing machines, printing, etc., can solve the problems of poor printing quality, affecting the positioning and clamping of positioning plates, and low efficiency, so as to improve the accuracy of actions, The effect of improving the continuity of movement and improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] The present invention will be further described in detail below through specific embodiments.

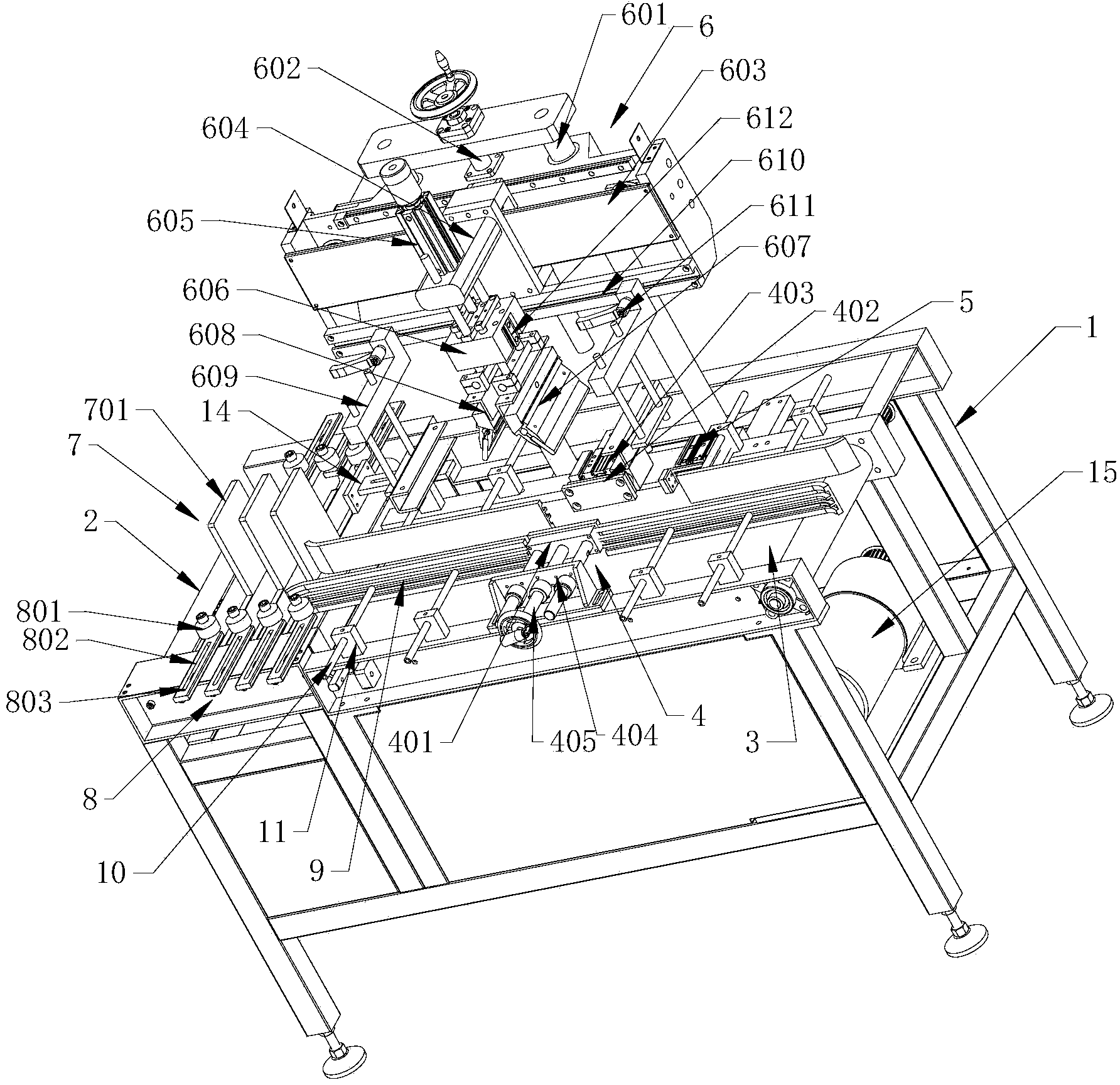

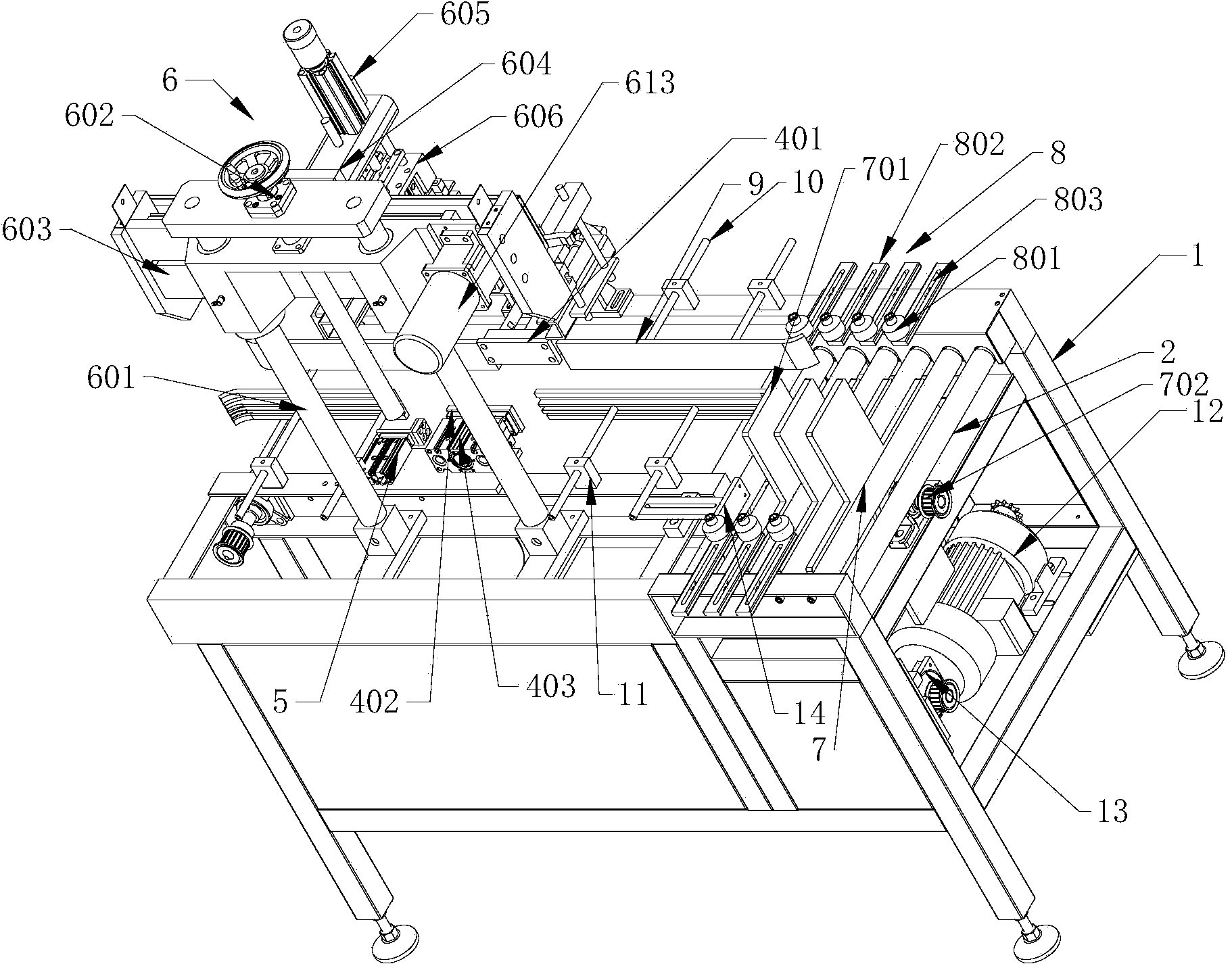

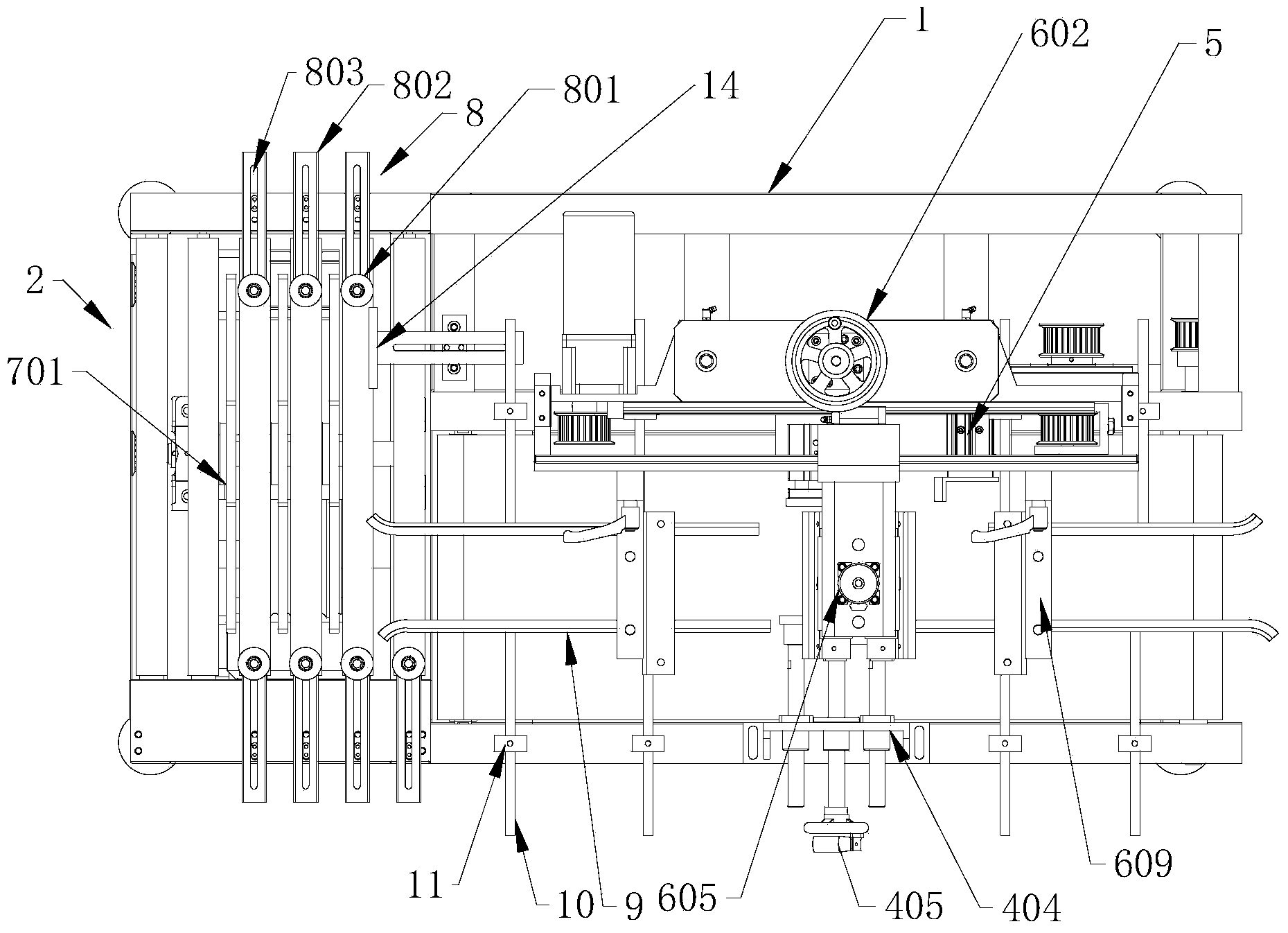

[0023] Such as Figure 1 to 4 As shown, a reversing screen printing device 6 of a battery packaging line includes a frame 1; a conveying roller set 2 that is rotatably installed on the frame 1, and the conveying roller set 2 includes an entrance section and a delivery section whose conveying directions are parallel to each other. The conveying roller set 2 includes a number of parallel and spaced conveying rollers. The conveying rollers are rotatably installed on the frame 1, and the entering section and the outgoing section are determined when the battery is transported on the conveying roller set 2. figure 1 , 3 As an example, in the figure, the conveying roller set 2 on the upper part of the paper surface of the cross-shaped turning frame 701 is the entry section, and the lower part of the paper surface is the delivery section, and the conveying direction is from left to right...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap