Double luffing combined boom swing mechanism, lifting device and container transport vehicle

A swing mechanism and lifting device technology, which is applied to cranes and other directions, can solve the problems of complex operation of lifting devices, affect the use effect, and inconvenient operation, and achieve the effects of low cost, convenient maintenance, and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0021] For the convenience of description, the "left" and "right" referred to below are consistent with the left and right directions of the drawings themselves.

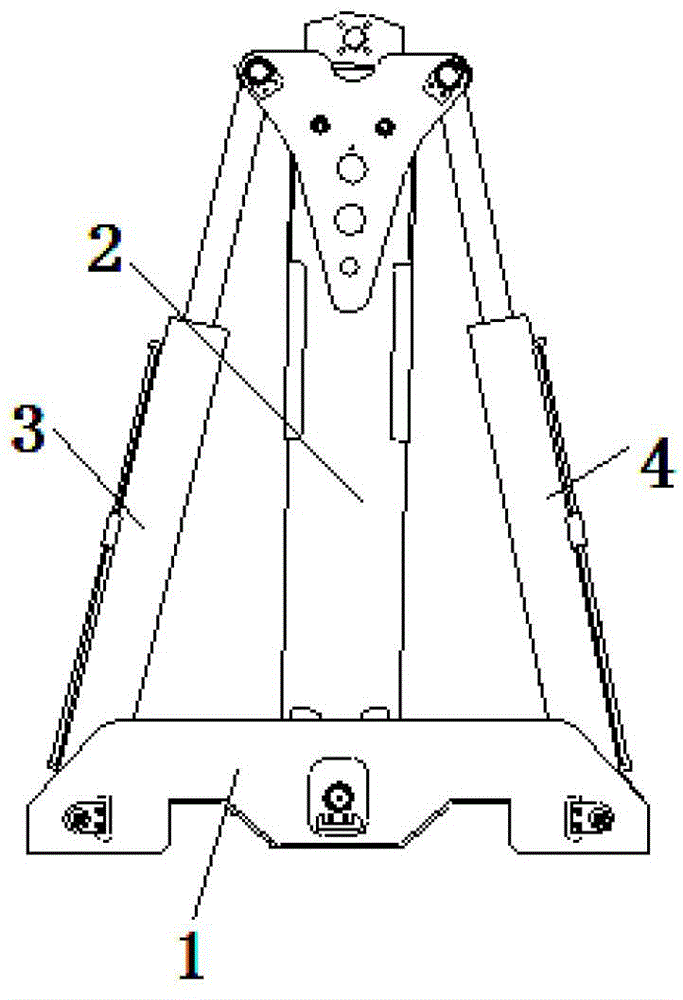

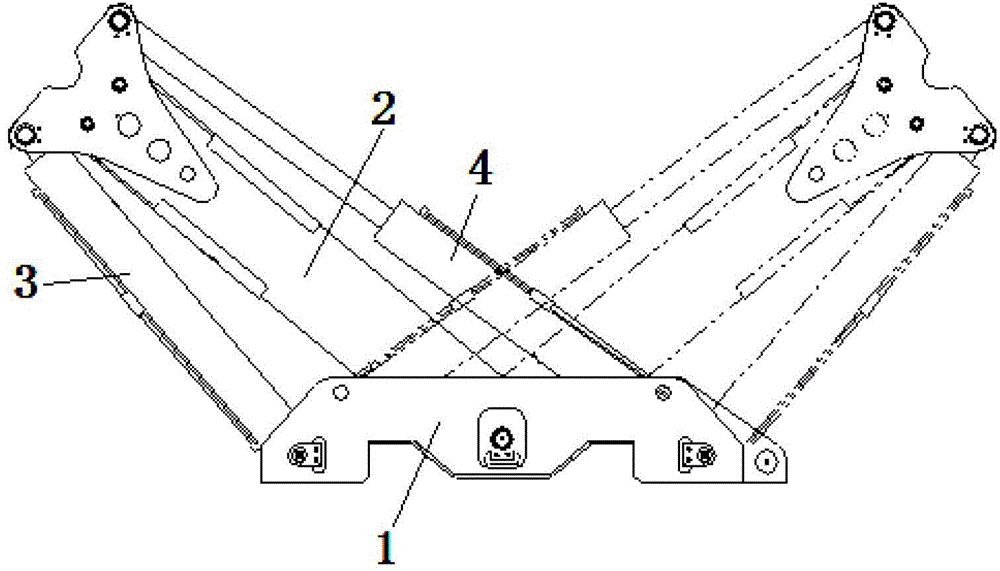

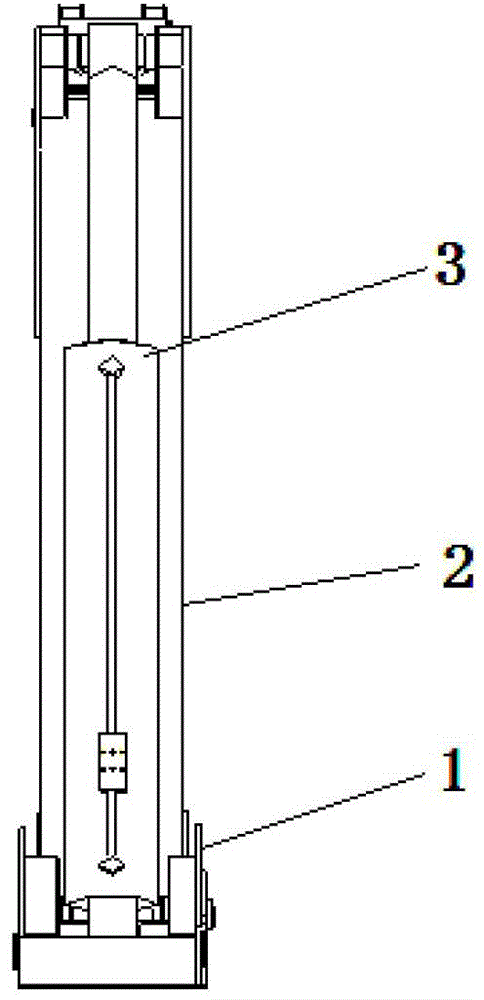

[0022] Such as Figure 1-5 As shown, the double-luffing combined boom swing mechanism of the container transport vehicle provided by the present invention includes a base 1 , a boom 2 , a left luffing cylinder 3 and a right luffing cylinder 4 . Among them: the corresponding positions on the left and right sides of the base 1 are respectively provided with hinge point holes, and one end of the left luffing cylinder 3 is connected to the left side of the base 1 through the first pin 31 , the first bolt 32 and the first washer 33 At the same time, one end of the right luffing cylinder 4 is connected in the hinge hole on the right side of the base 1 through a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com