Teeth for disperser plate having grooves and taper

A technology of dispersing machine and machine disc, applied in paper machine, wet end of paper machine, textile and paper making, etc., can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

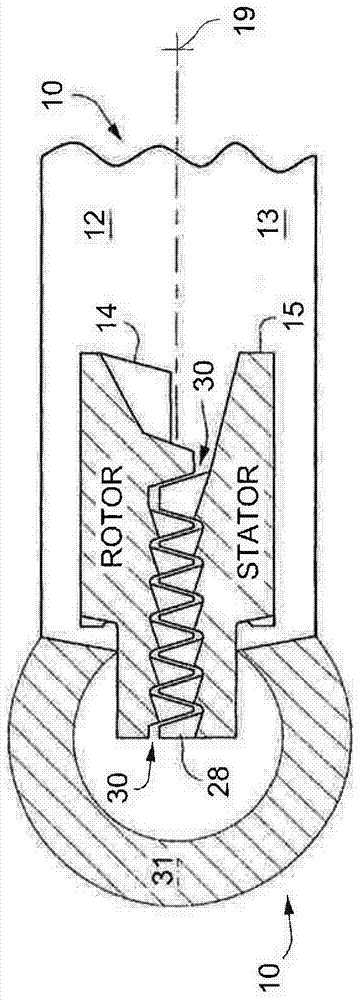

[0036]Increasing the number of contact edges for the material can improve the breakdown of dirt and stickies in the fiber stock and increase the efficiency of the disperser.

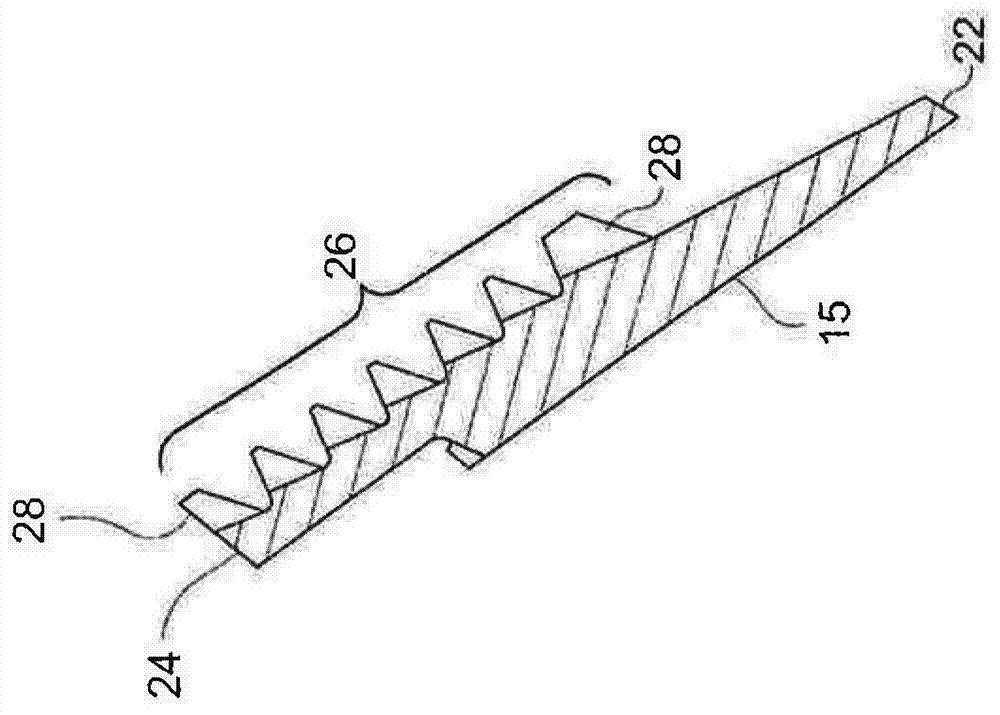

[0037] A disperser disk segment according to any of the embodiments of the present disclosure has at least one tooth, the inner or outer frontal surface of the tooth comprising at least two grooves. Any combination of groove length, width, shape, grooves of decreasing width, grooves of decreasing depth, or angled grooves on the inner or outer frontal surface of teeth with at least two grooves can be used.

[0038] Although the grooves are depicted as oblong, cylindrical or conical in the drawings, the grooves may be triangular, pyramidal or quadrangular in other embodiments.

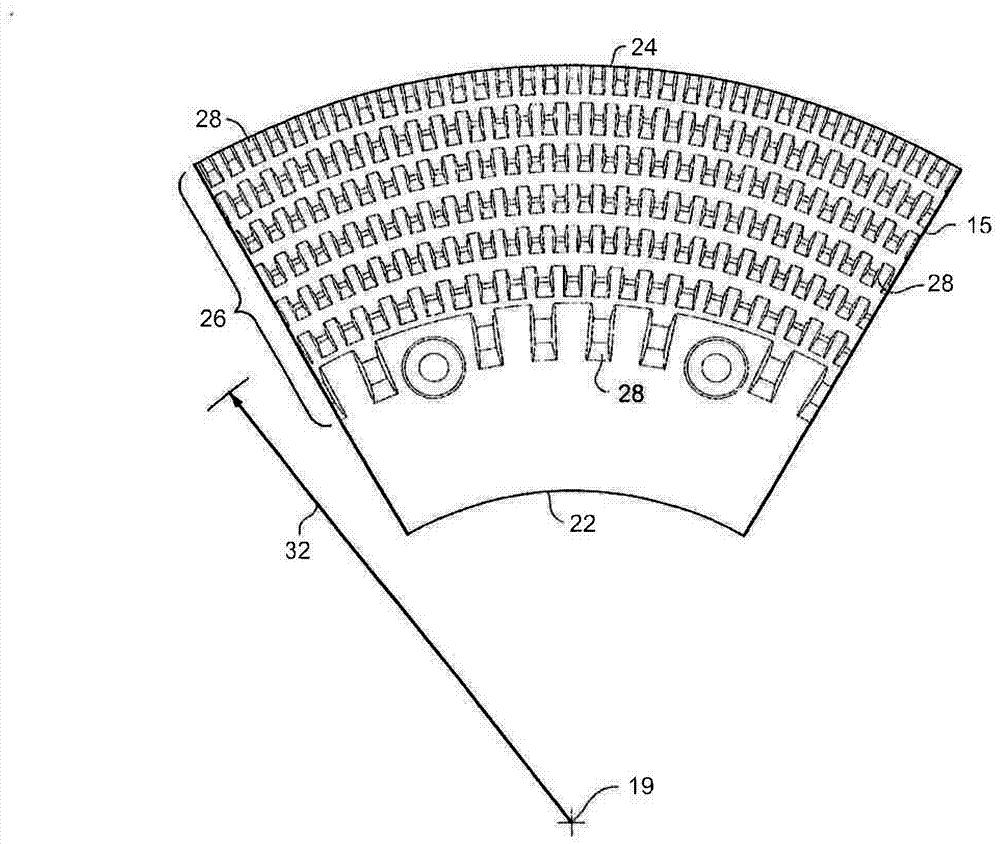

[0039] Figures 1a, 1b and 1c show a conventional disk section 10 of a disperser. In FIG. 1 a, the conventional disk segment 10 is a turntable disk segment 15 . Each conventional disc segment 10 is a die-cast metal piece in the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com