Motor spindle capable of dissipating heat

A technology for motors and heat sinks, applied in the field of motor spindles, can solve problems such as component fatigue, rotor 3 and spindle 4 cannot be quickly dissipated, reduce motor performance and life, and achieve the effect of increasing gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to illustrate the central idea of the present invention expressed in the column of the above-mentioned summary of the invention, it is expressed in specific embodiments. Various objects in the embodiments are drawn according to the scale suitable for illustration and description, rather than according to the scale of the actual components, and are described first.

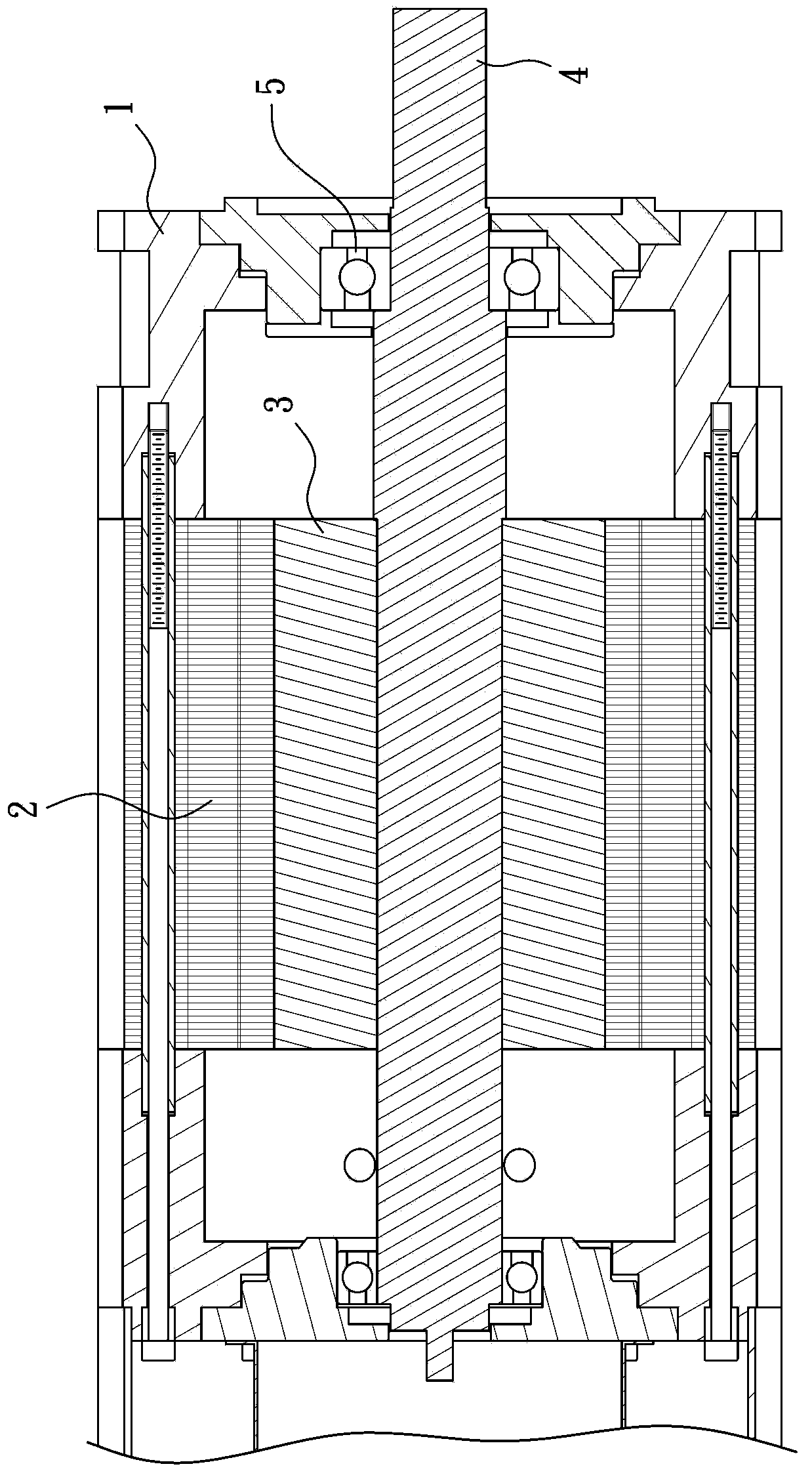

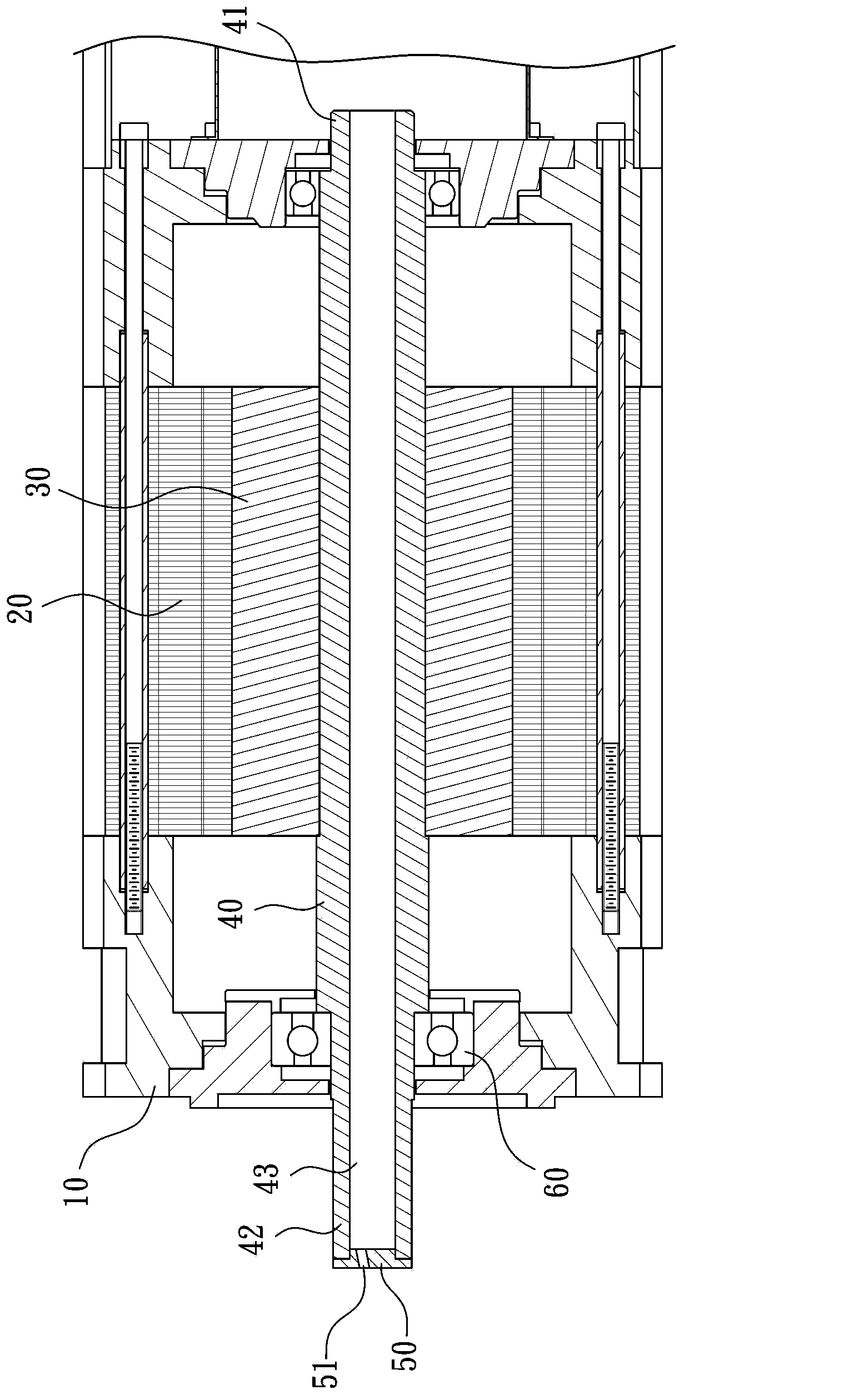

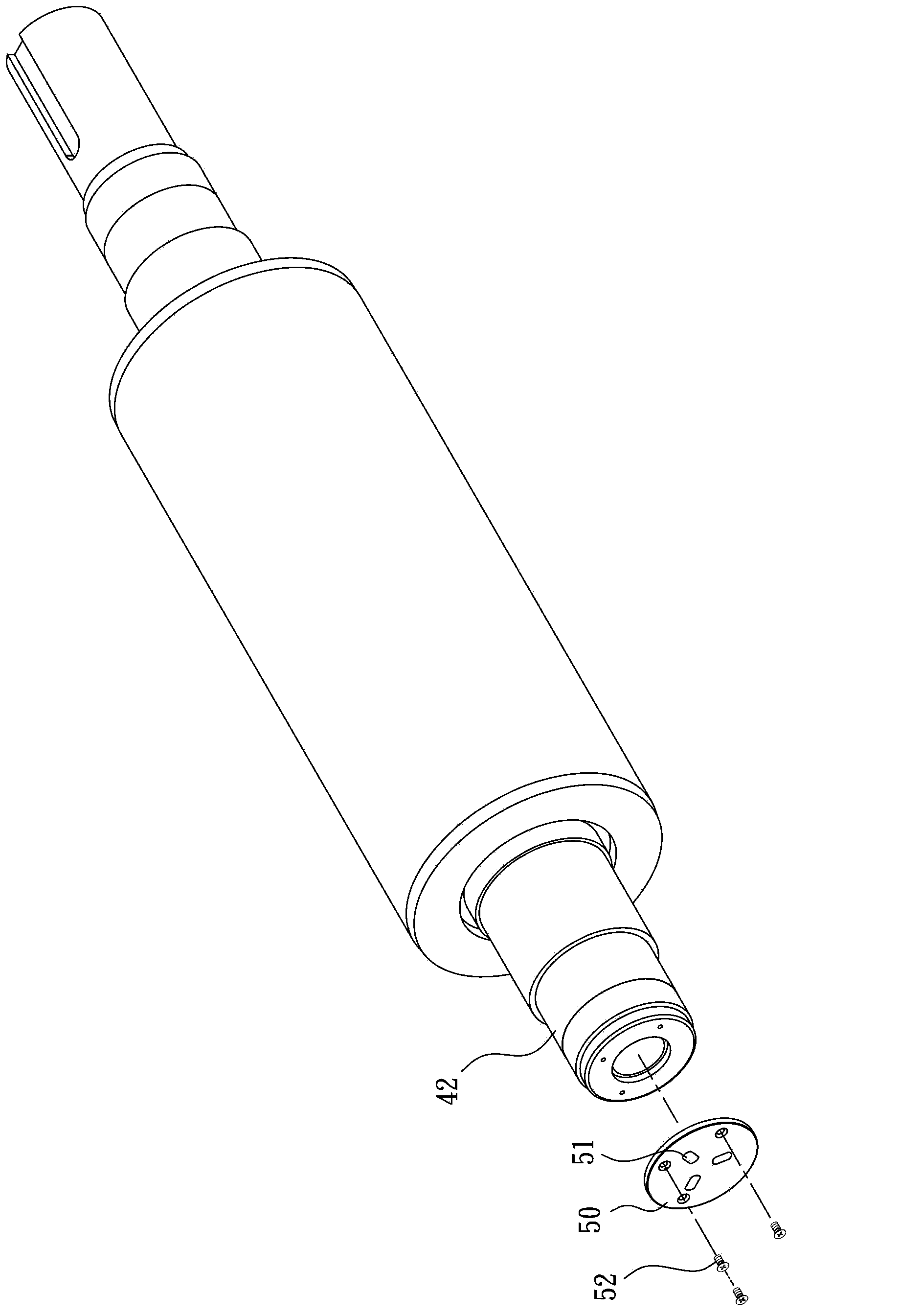

[0027] see figure 2 and image 3 as shown, figure 2 It is a structural schematic diagram of the heat-dissipating motor spindle of the present invention, image 3 It is a schematic diagram of the appearance of the heat-dissipating motor spindle of the present invention. Basic structure of the present invention is roughly as usual, and it comprises:

[0028] A body 10 has an inner space, and a stator 20 is fixed on its inner wall. The stator 20 has a hollow area inside, and a rotor 30 is pivoted, and a gap is provided between the rotor 30 and the stator 20. When the stator 20. When the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com