High-temperature corrosion-resistant nozzle for coal-fired power station

A coal-fired power station, high-temperature protection technology, applied in the direction of combustion chamber, combustion control, combustion method, etc., can solve the problems of furnace combustion and adverse effects of airflow organization, etc., to improve gas flow rate, expand downward purge area, and reduce disturbance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific examples. The following examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

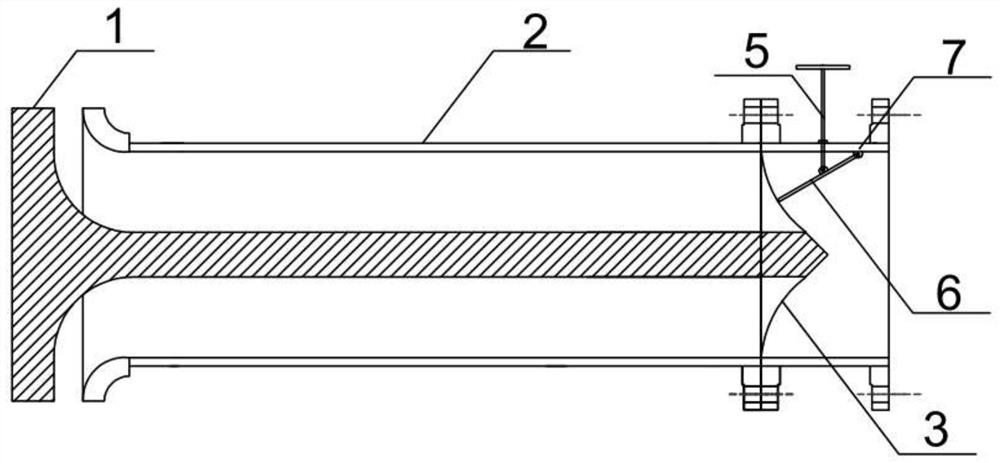

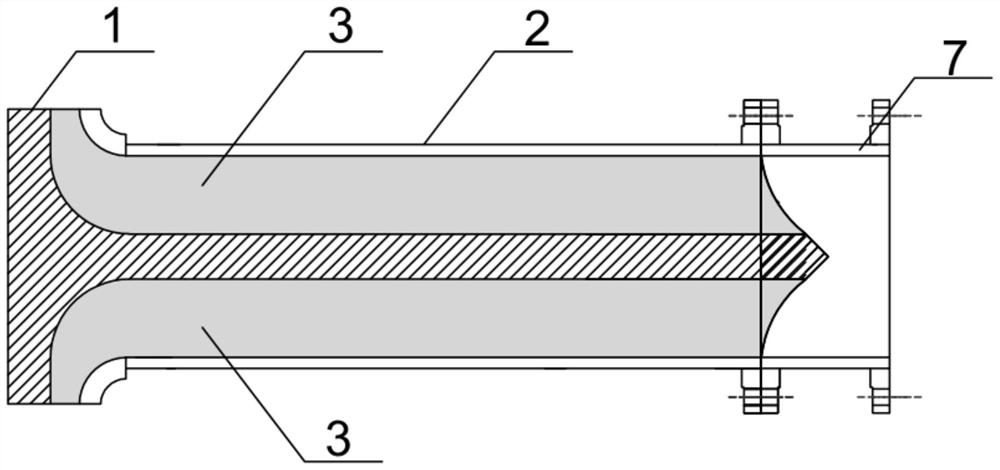

[0022] A kind of anti-high temperature corrosion nozzle of coal-fired power station, such as figure 1 , including a high-temperature-resistant stainless steel cylinder 2, the cylinder 2 is equipped with a water-cooled wall, and the cylinder 2 is provided with an air distribution cone 1 for guiding and distributing the purge wind. The rear end opening of the body 2 penetrates into the cylinder body 2 .

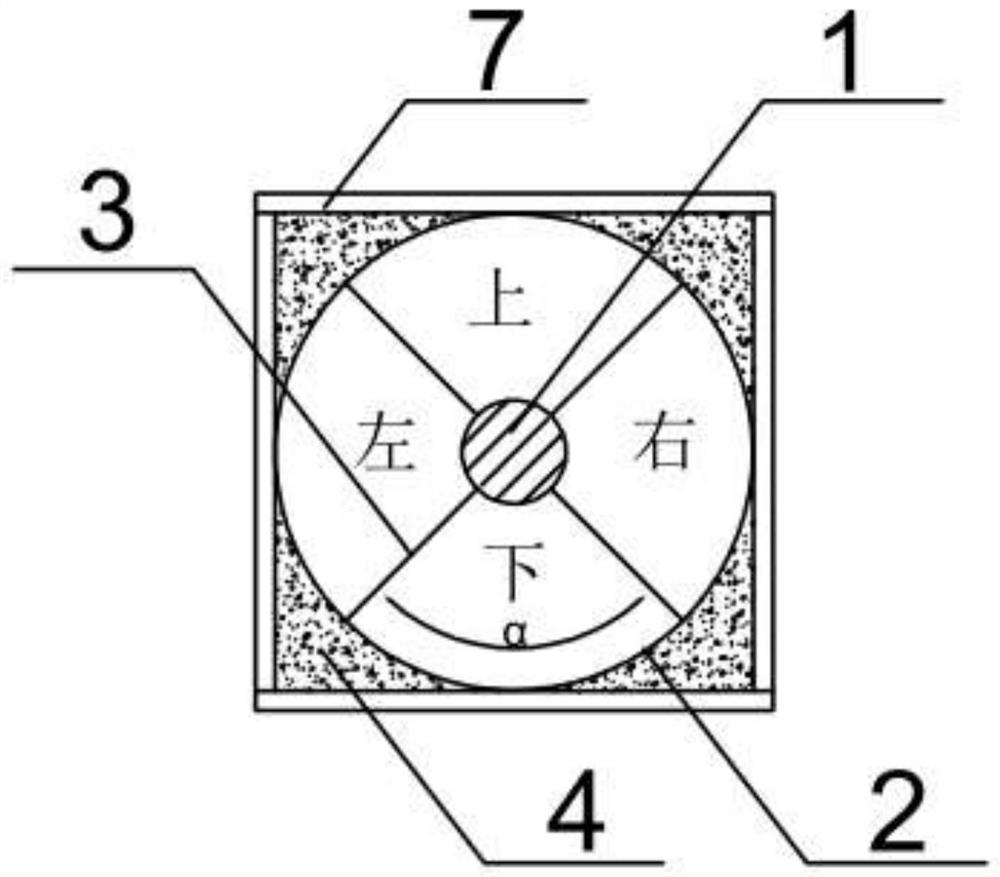

[0023] In order to precisely control the upper and lower purge winds and enhance the purge effect, metal baffles 3 for guiding the airflow are arranged around the air distribution cone 1 inside the cylinder 2. The baffles 3 are four pieces, and the cylinder The purge air channel in the body 2 is divided into four parts: upper, lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com