An optical fiber fusion tapering machine equipped with an optical fiber electromagnetic clamping device

The technology of a clamping device and a taper machine, which is applied to the coupling of optical waveguides and other directions, can solve the problems of difficult product quality control, difficult operation, low clamping reliability, etc., so as to reduce the optical fiber alignment operation and clamping Reliable and balanced effect to ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

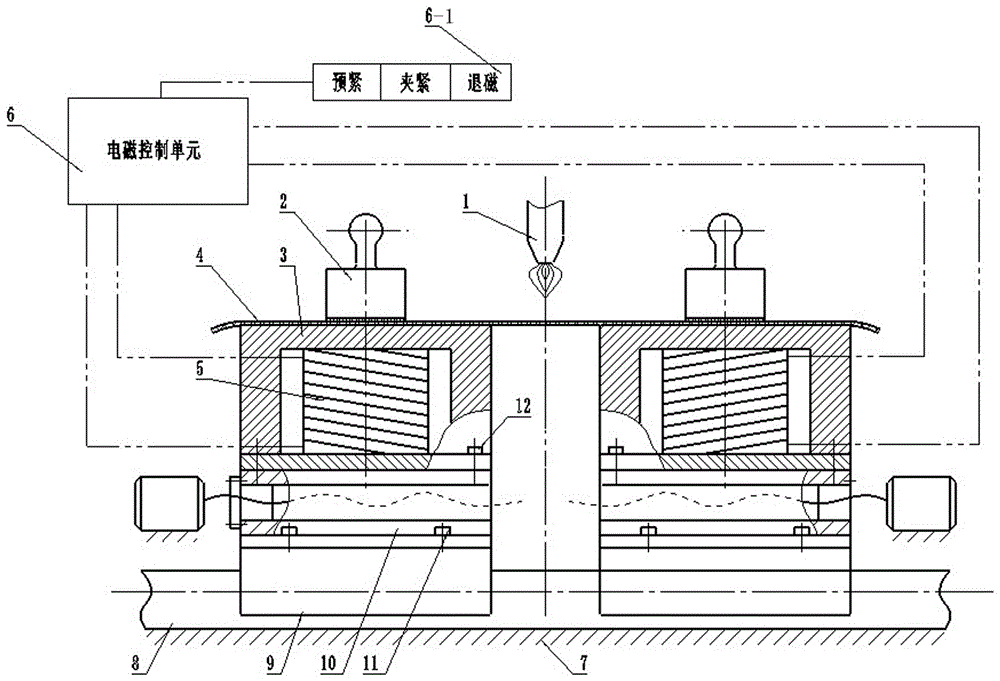

[0020] refer to figure 1 , an optical fiber fusion tapered machine provided with an optical fiber electromagnetic clamping device, comprising an optical fiber sintering flame nozzle 1, a base 7, a ball guide rail 8 fixed on the base 7, and two left and right sides that can move on the ball guide rail 8 A sliding seat 9, each sliding seat 9 is fixed with a ball screw seat 10 by screws 111, each ball screw seat 10 is respectively equipped with a clamping device for an optical fiber tapering machine, and a fiber optic tapering machine is used for clamping The fixture seat bottom plate 3-3 is fixed on the ball screw seat 10 by the screw II 12 of the device.

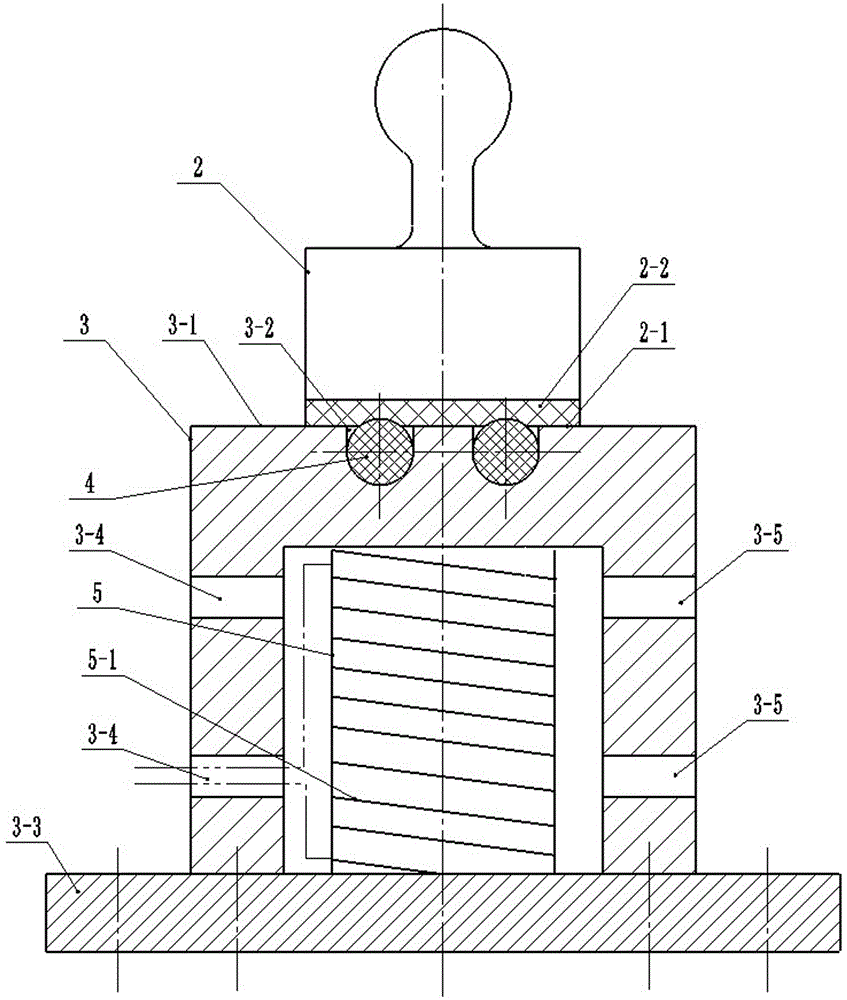

[0021] refer to figure 2 , the optical fiber electromagnetic clamping device includes: a fixture seat 3, the top surface 3-1 of the fixture seat is provided with a lower groove 3-2 for clamping the optical fiber 4, and the bottom of the fixture seat 3 is also provided with a fixture seat bottom plate 3 -3; electromagnet 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com