An optical fiber de-energized electromagnet clamping device for an optical fiber fusion tapered machine

A technology of power-loss electromagnet and cone-pulling machine, which is applied to the coupling of optical waveguides, etc., can solve the problems of insufficient suction force of the clamping device, high power consumption of electromagnets, and difficult operation, etc., so as to reduce the optical fiber alignment operation. Action and suction are constant, reliable and balanced, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

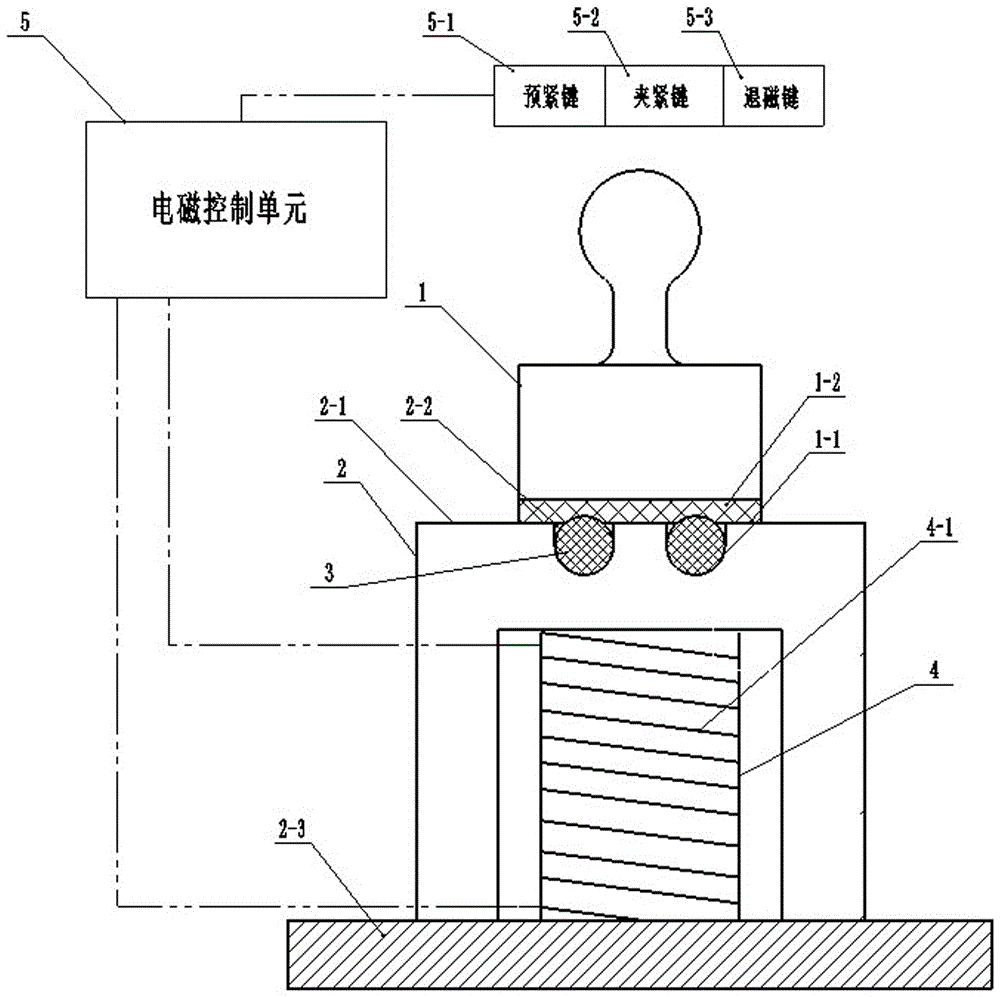

[0016] refer to figure 1 , an optical fiber de-energized electromagnet clamping device for an optical fiber fusion tapered machine, comprising:

[0017] The fixture seat 2, the top surface 2-1 of the fixture seat is provided with a groove 2-2 for clamping the optical fiber 3, and the lower part of the fixture seat 2 is also provided with a fixture seat bottom plate 2-3;

[0018] The de-energized electromagnet 4, the de-energized electromagnet 4 is installed in the cavity of the clamp seat 2, and the de-energized electromagnet 4 generates clamping magnetic force after power-off;

[0019] Pressure hammer 1, the bottom surface of the pressure hammer 1 is provided with silica gel to cooperate with the groove 2-2 so as to clamp the optical fiber 3, at least a part of the pressure hammer 1 is made of soft magnetic material, and the soft magnet Under the magnetic force of the de-energized electromagnet 4, the material presses the hammer 1 to the top surface 2-1 of the fixture seat, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com