Touch panel and manufacturing method thereof

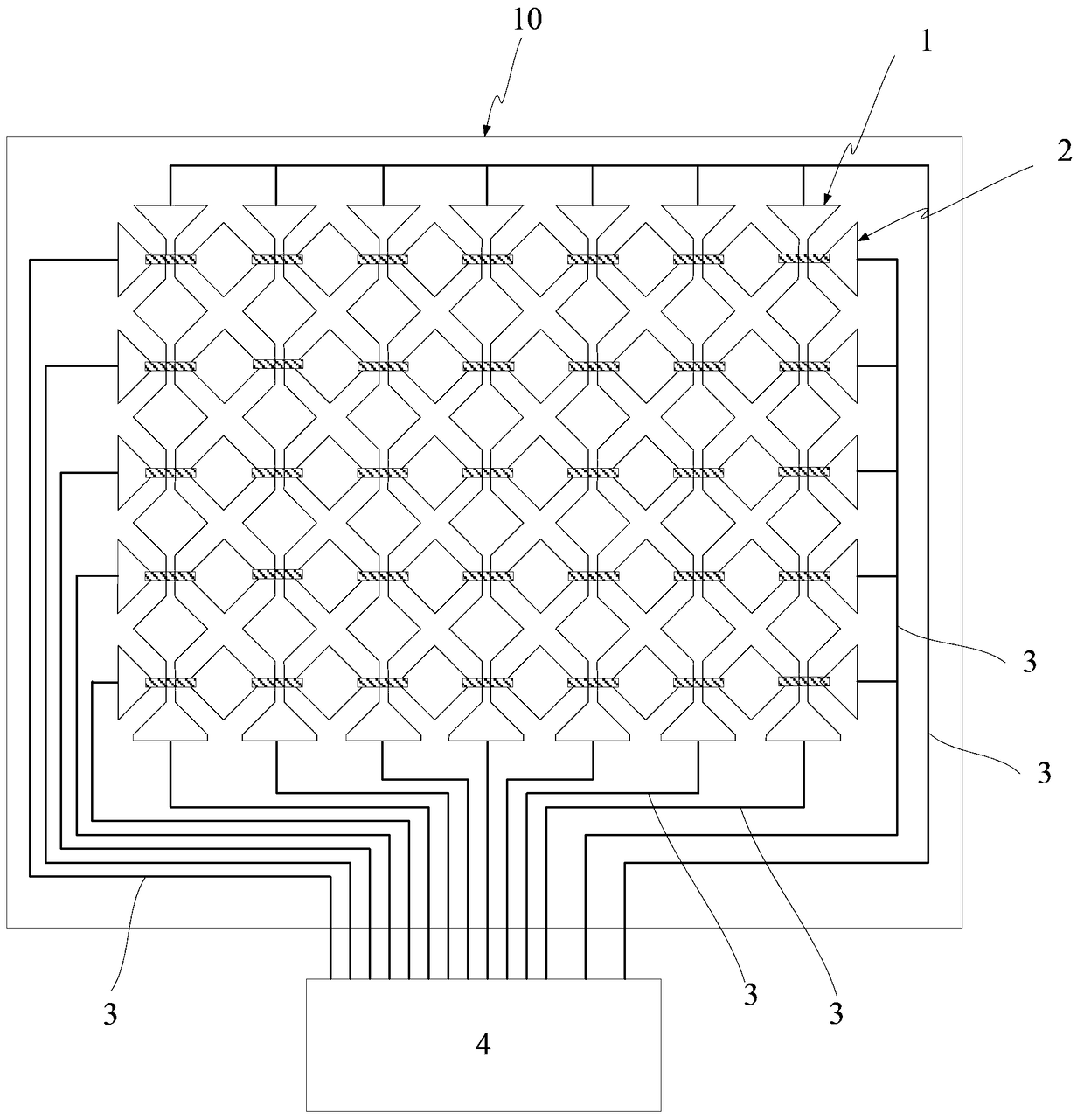

A touch panel and substrate technology, which is applied in the fields of instruments, computing, electrical and digital data processing, etc., can solve problems such as the inability to meet the needs of narrow-frame touch display devices, and achieve the effect of improving signal attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

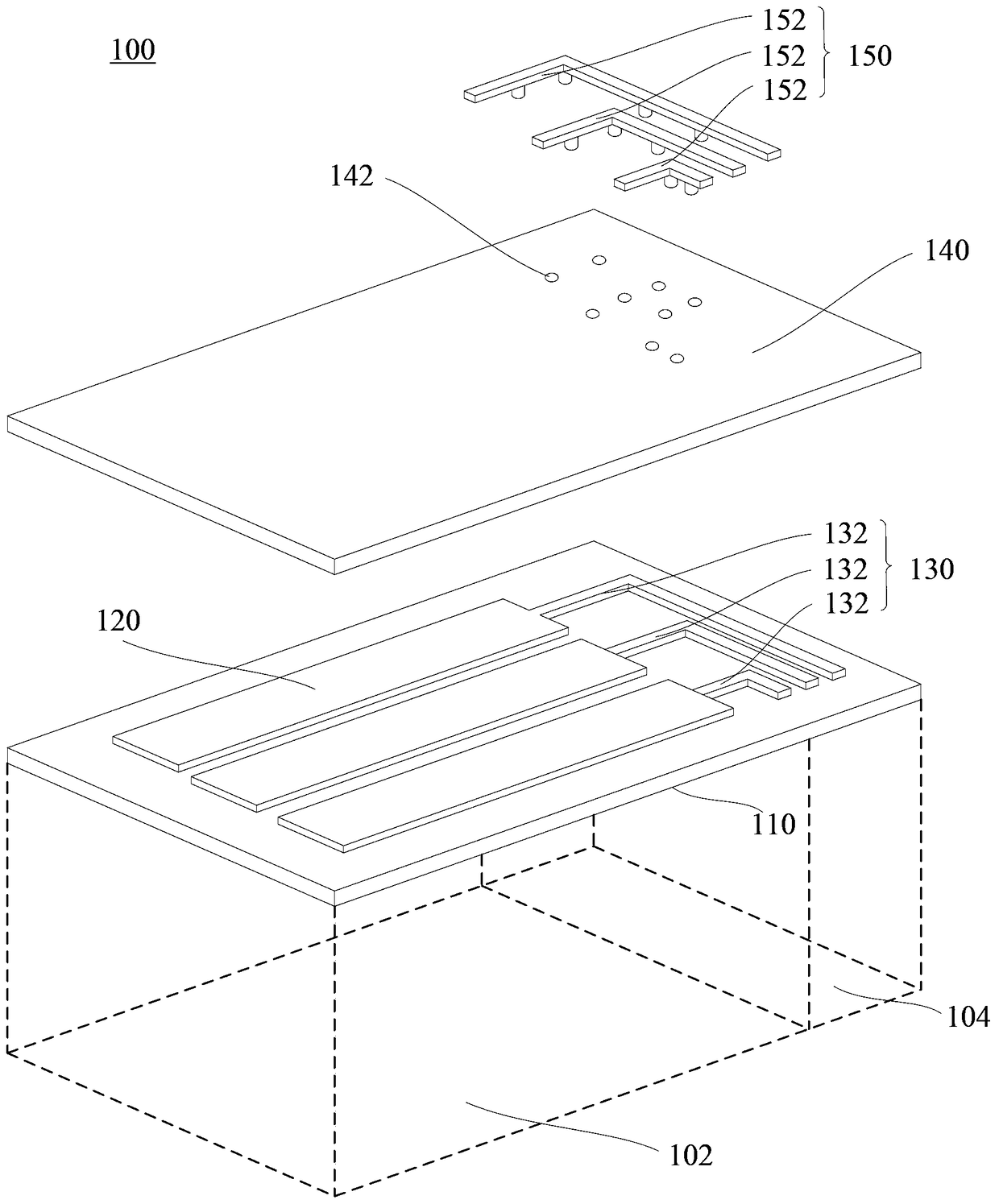

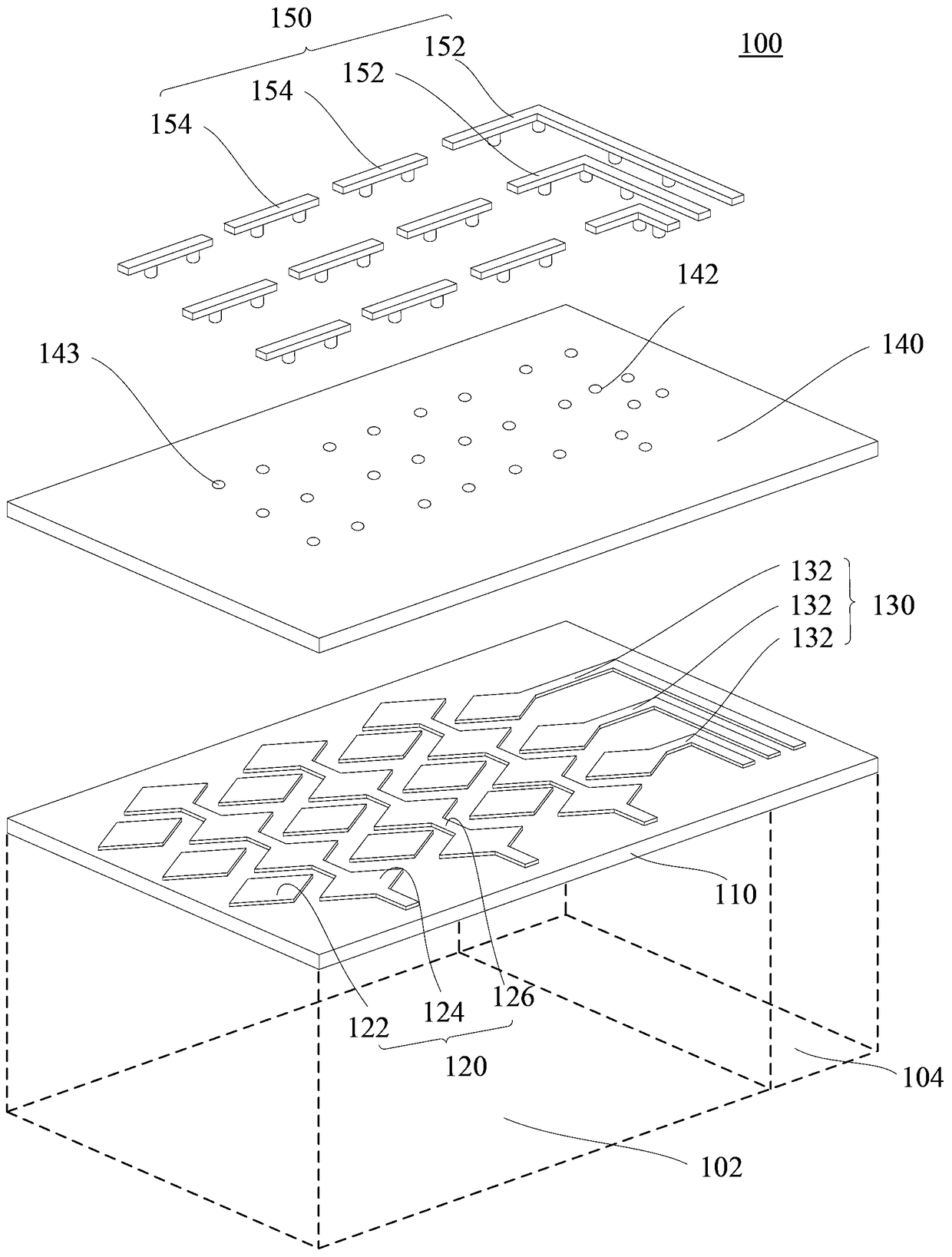

[0017] see figure 2 , is an exploded view of the touch panel of an embodiment. The touch panel 100 defines a sensing area 102 and a circuit area 104 located at the edge of the sensing area 102 . The touch panel 100 includes an electrode layer 120 , a first wire layer 130 , an insulating layer 140 and a second wire layer 150 . The position and quantity of the wiring area 104 can be adjusted according to the specific structure of the electrode layer 120 and the number of the first wiring 132 contained in the first wiring layer 130 , for example, the wiring area 104 can be located on one side or more than one side of the electrode layer 120 . The electrode layer 120 is located in the sensing area 102 , and the first wire layer 130 is located in the circuit area 104 and is electrically connected to the electrode layer 120 . The second wire layer 150 is electrically connected to the first wire layer 130 in the wiring area 104 . The insulating layer 140 can be disposed between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com