Halogen-free flame retardant thin-wall type control cable for special motor train

A technology for controlling cables and thin walls, applied in the direction of insulated cables, flexible cables, cable/conductor manufacturing, etc., to achieve the effects of excellent flexibility, good roundness, and strong anti-electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

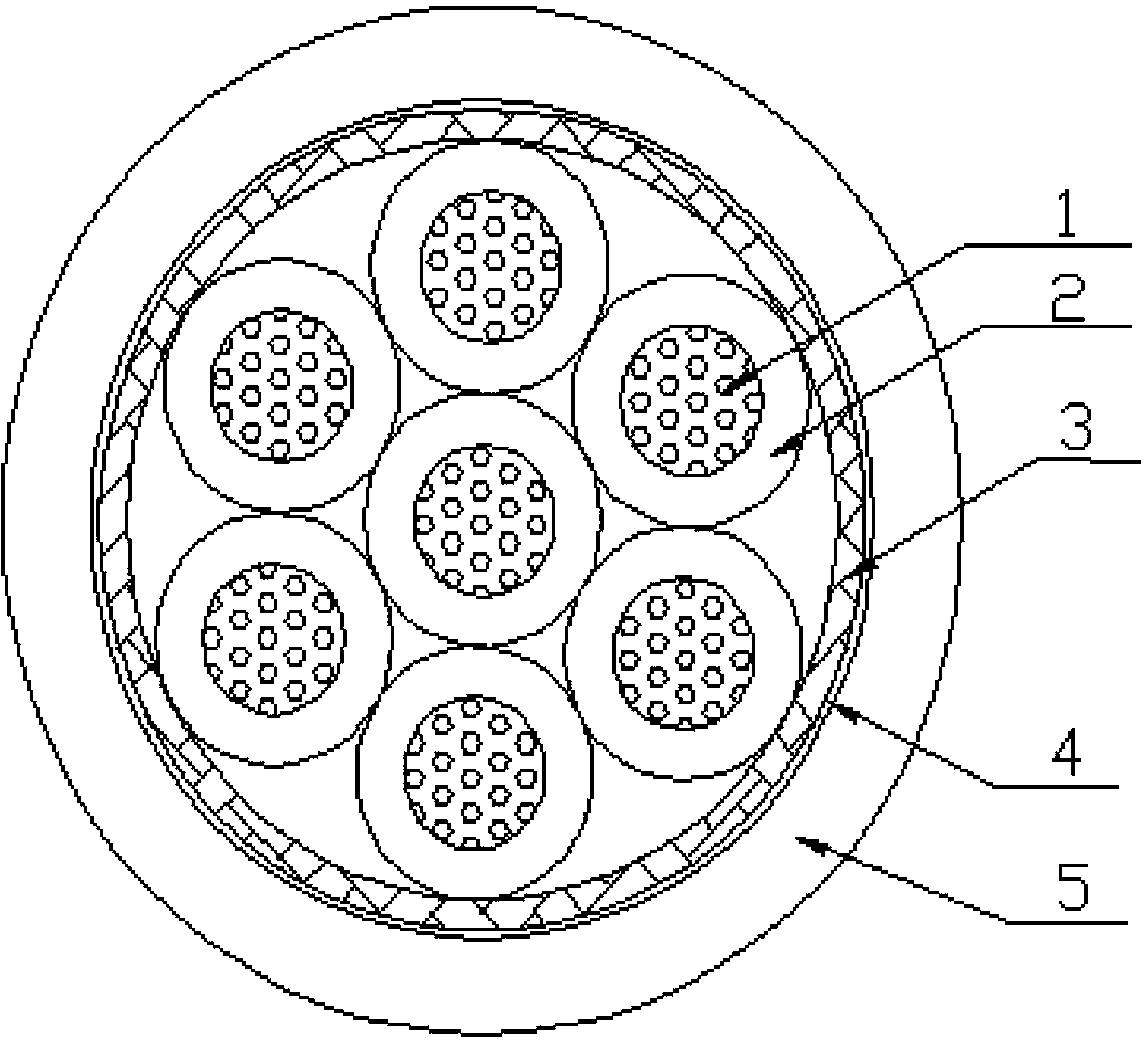

[0015] Such as figure 1 as shown, figure 1 It is a schematic cross-sectional structure diagram of a halogen-free flame-retardant thin-walled special motor vehicle control cable proposed by the present invention.

[0016] refer to figure 1 , a halogen-free flame-retardant thin-walled special motor vehicle control cable. The conductor core 1 is covered with an insulating layer 2, and the two form a core. Among them, the conductor core 1 is a soft conductor composed of five types of tinned copper wires concentrically twisted. The twisting pitch is not more than 20 times the outer diameter of the conductor. It adopts a concentric bundle twisted structure, which has good roundness, low signal attenuation, and is convenient for construction and wiring. When the terminal is installed; the insulation layer 2 is prepared by thin-walled extrusion technology of Class III oil-resistant materials that meet the standards. It is low-smoke, halogen-free, and flame-retardant. The outer diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com