Evaluation method of refining device parts prone to corrosion

An evaluation method and corrosion evaluation technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems that have not yet been reliably and scientifically evaluated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

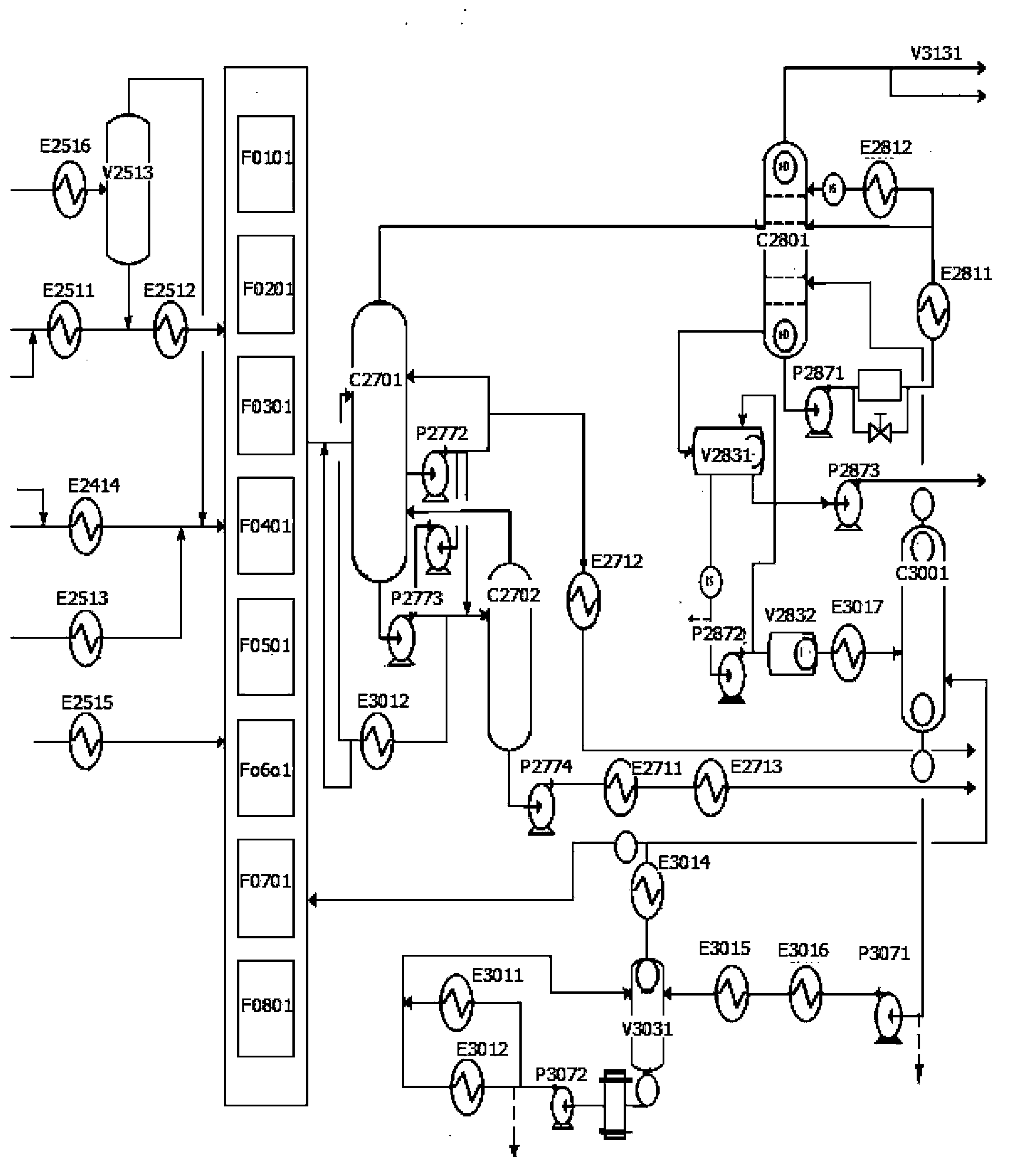

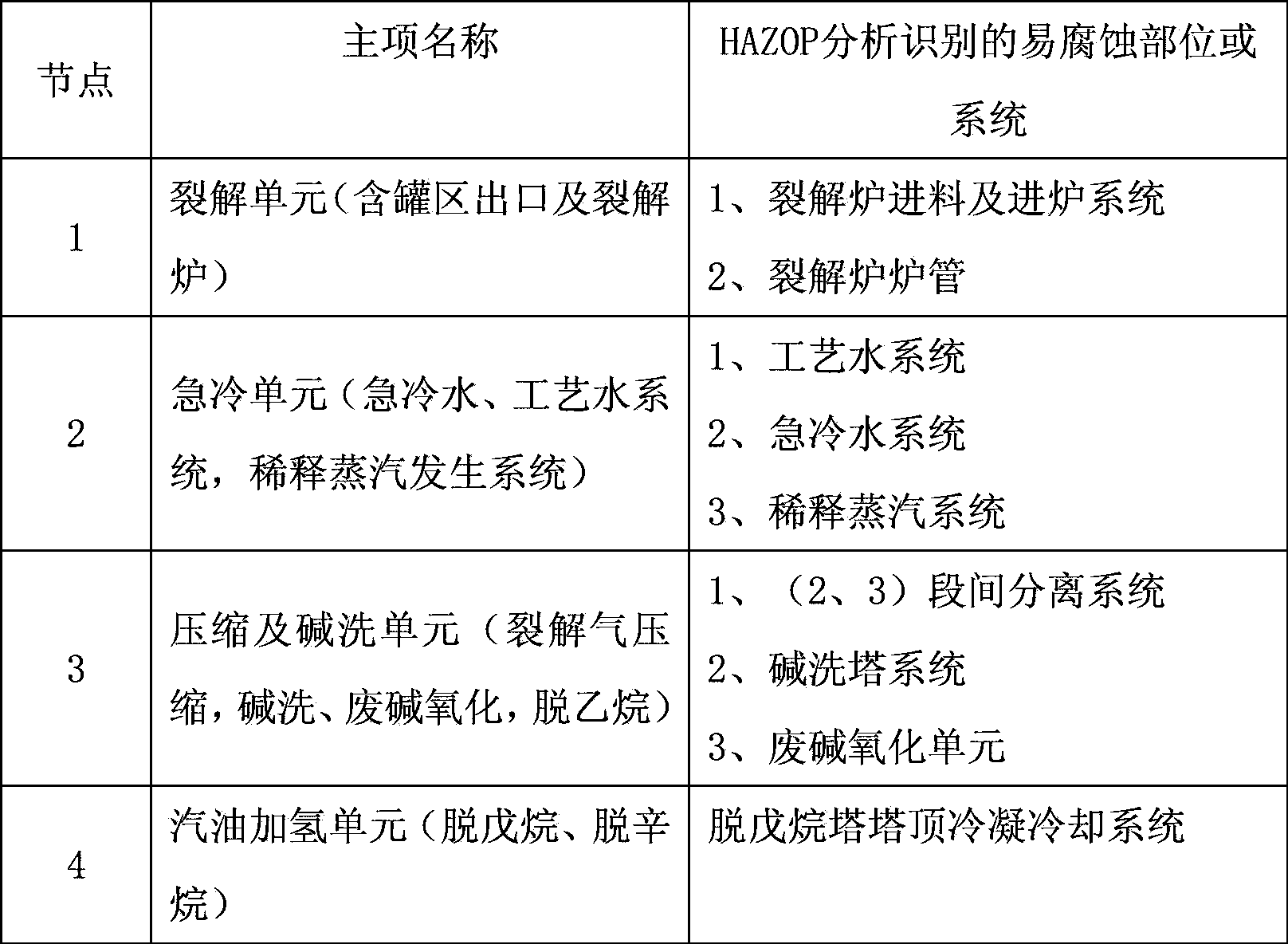

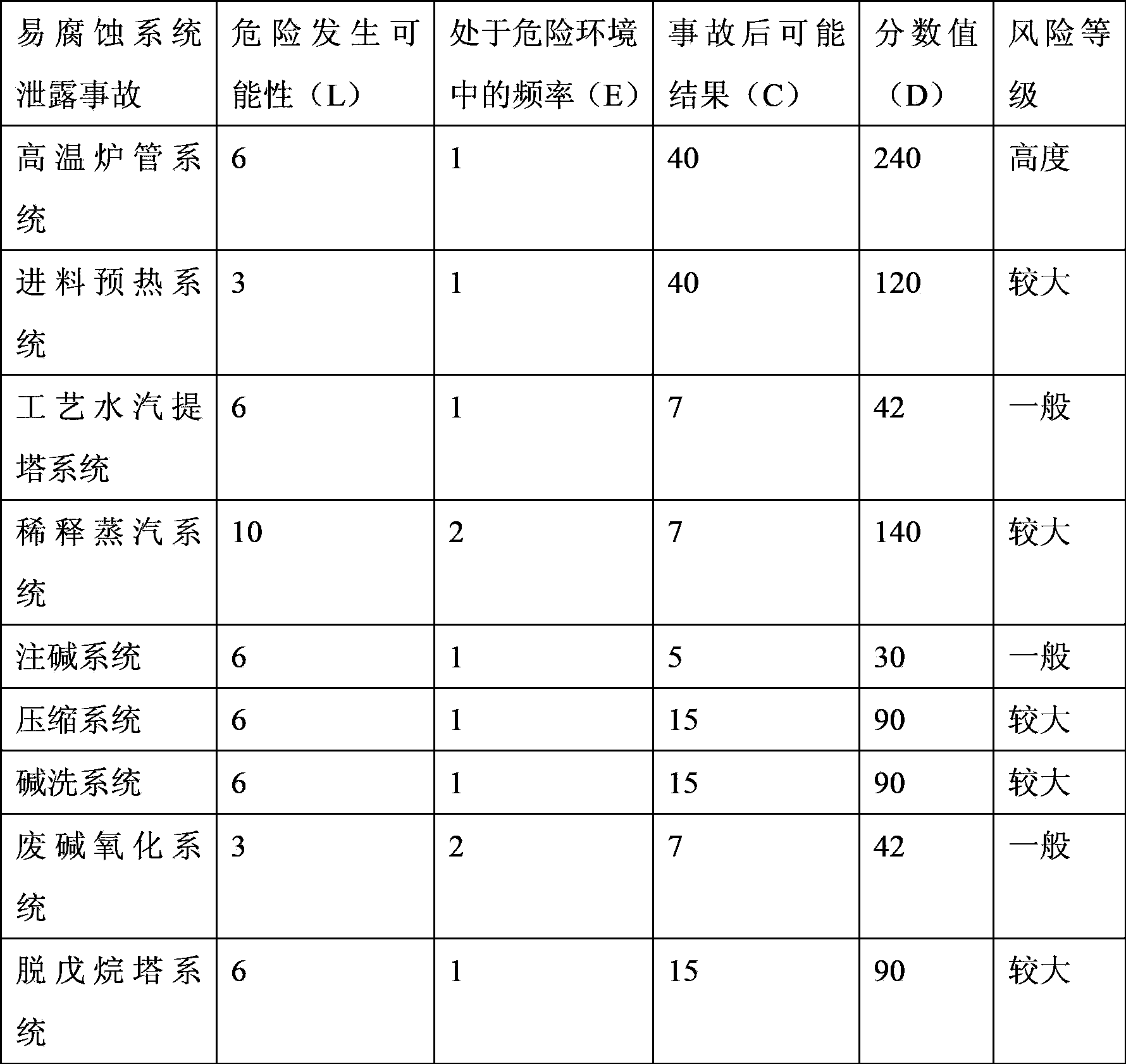

[0019] Take the newly built 1 million tons / year cracking unit as an example:

[0020] 1) Through the RBI risk analysis of 259 pieces of equipment and 5025 pipelines, it is determined that the main failure modes are: internal corrosion thinning, stress corrosion cracking and external corrosion. The internal corrosion thinning includes high-temperature sulfide corrosion, high-temperature H 2 S / H 2 Corrosion, corrosion and high temperature oxidation of wet hydrogen sulfide / carbon dioxide gas, stress corrosion cracking including wet H 2 Sulfide stress corrosion cracking, carbonate stress corrosion cracking and alkali stress corrosion cracking in S environment. High-temperature sulfide corrosion mainly occurs in the pyrolysis gas pipeline from the cracking furnace outlet to the 10-C-2701 oil washing tower in the cracking section; 2 S / H 2 Corrosion mainly occurs in the pyrolysis gas pipeline from the outlet of the cracking furnace in the cracking section to the 10-C-2701 oil scru...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap