Integrated automatic microscopic welding equipment

A technology of welding equipment and automatic spot welding, which is applied in welding equipment, resistance welding equipment, welding power supply, etc. It can solve the problems of independent adjustment, overall weight of the machine head, and the accuracy of electrode force cannot meet the requirements of spot welding, etc., to achieve accurate electrode force Effect of improving output and spot welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

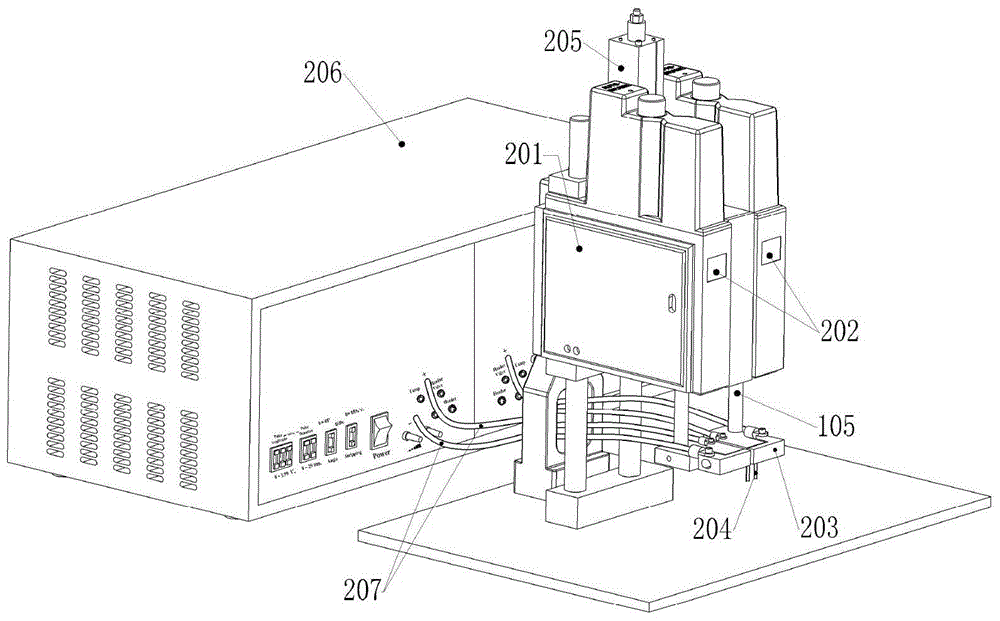

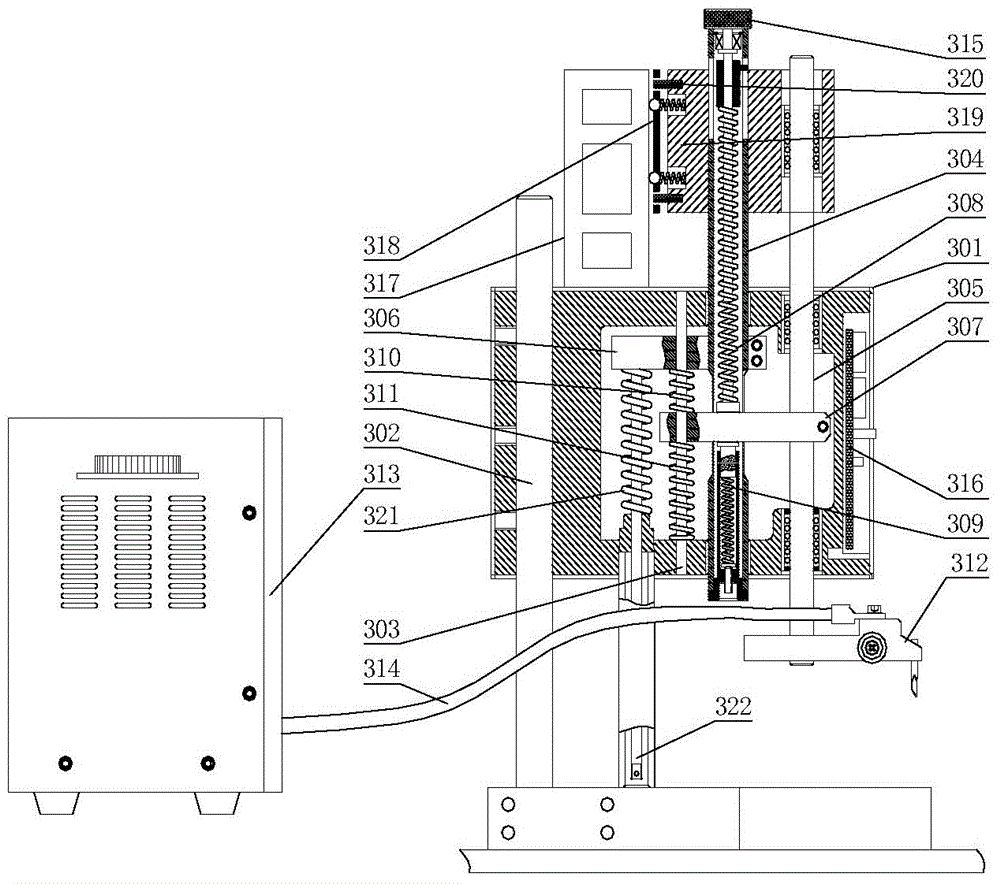

[0040] The present invention will carry out overall introduction according to following each aspect as follows: 1, overall structure; 2, two spot welding machine heads that are installed into one; 3, the head frame of spot welding machine; 4, resistance welding power supply; head clip.

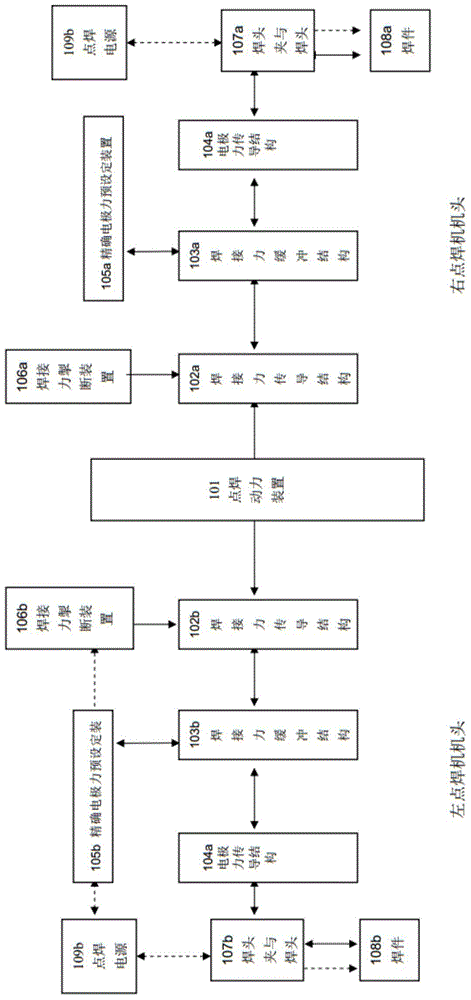

[0041] 1. First, combine the attached figure 1 Introduce the general structural block diagram of the present invention.

[0042] figure 1 While showing the overall structural frame of the spot welding equipment of the present invention, it also shows its structural principle, which includes a spot welding power device 101, welding force transmission structures 102a, 102b, welding force buffer structures 103a, 103b, electrode force transmission Structure 104a, 104b, precise electrode force preset device 105a, 105b, welding force breaking device 106a, 106b, welding head clip and welding head 107a, 107b, and the electrode force applied by the spot welding equipment of the present invention for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com