Motorcycle frame fixing rack for online production

A motorcycle and fixing seat technology, which is applied in the field of vehicle loading tooling, can solve the problems of not designing the main bracket, etc., and achieve the effect of simple structure, meeting the loading requirements, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

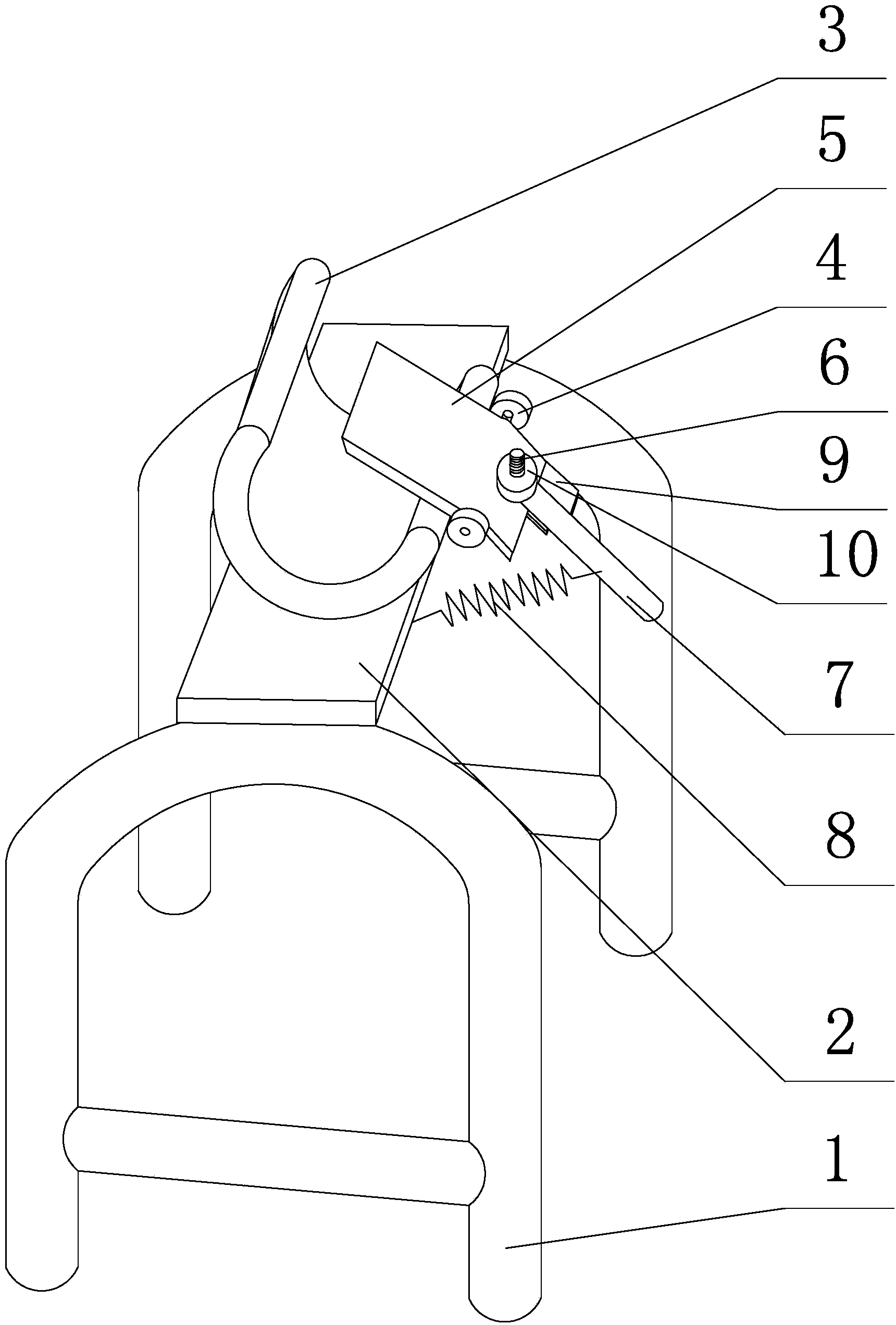

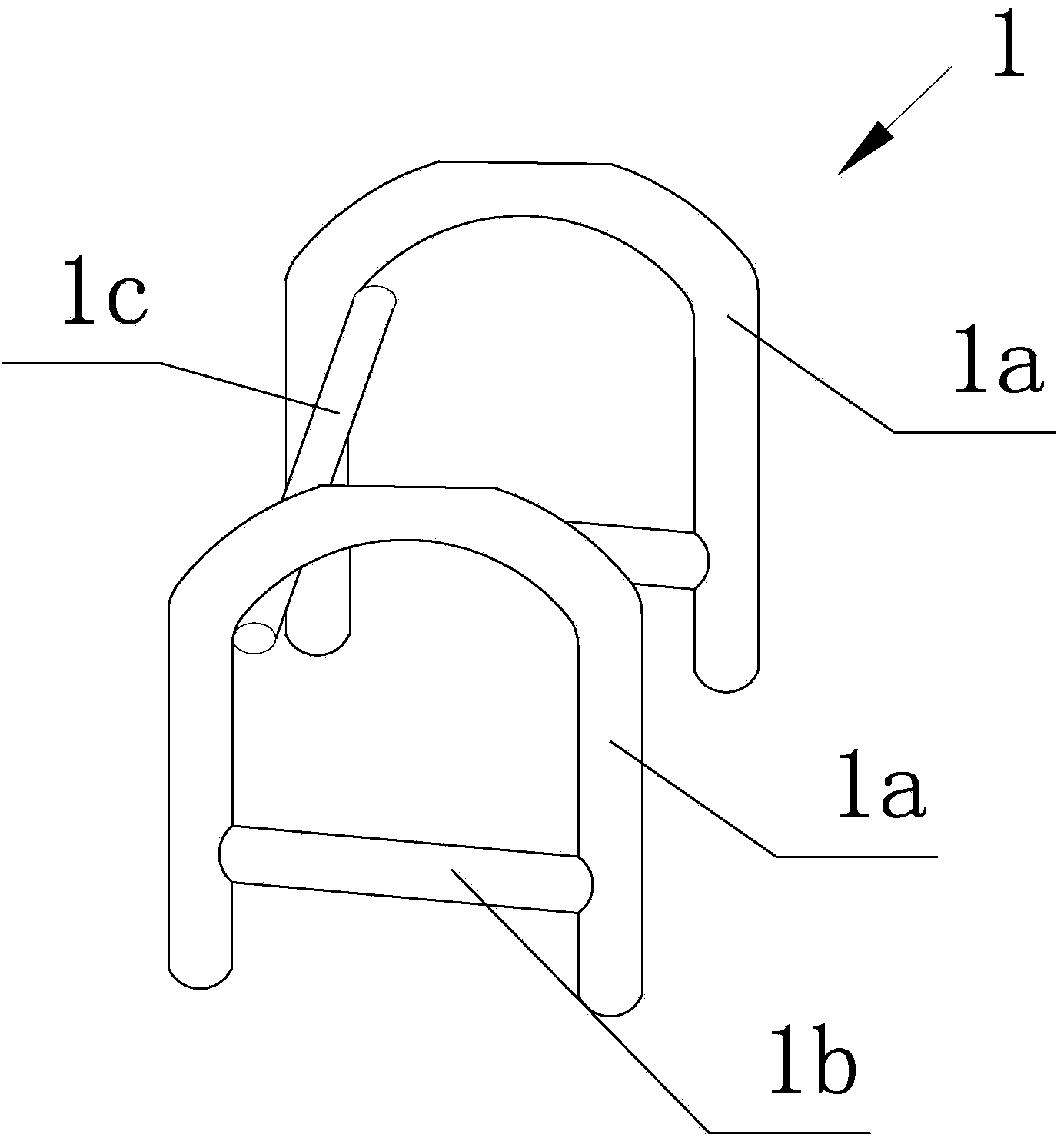

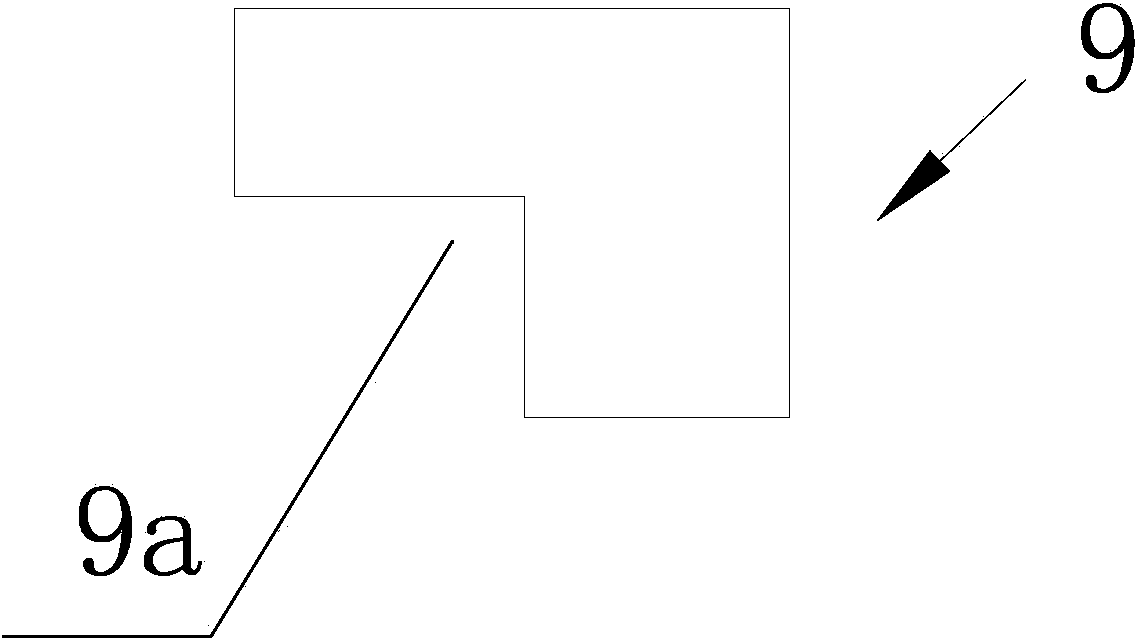

[0014] like figure 1 As shown, a motorcycle frame is fixed on the line, which consists of a four-legged support frame 1, a horizontal connecting plate 2, a semicircular arc plate 3, a hinge 4, a movable pressing plate 5, a vertical screw 6, a pressing plate handle 7, and a spring 8 , Handle limit plate 9, nut 10 etc. are formed.

[0015] The top of the four-leg support frame 1 is welded with a horizontal connecting plate 2 , and the top of the horizontal connecting plate 2 is welded with an upward semicircular arc plate 3 , and the horizontal connecting plate 2 plays the role of supporting the semicircular arc plate 3 . The opening of semicircular arc plate 3 is upwards, just puts into for the lower beam of vehicle frame. A hinge 4 is welded on one side of the semicircular arc plate 3, and the hinge 4 is parallel to the axis of the semicircular arc plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com