Color-changing water-based ink containing hollyhock flower extract and preparation method thereof

A technology of hollyhocks and water-based ink, applied in the field of printing ink, can solve the problems of loss of artistic value and use value of printed products, and achieve the effect of bright patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The ink preparation process can be divided into four stages: batching, stirring pre-dispersion, grinding fine dispersion and ink adjustment.

[0038] 1) Ingredients: Water-soluble toner, water-soluble acrylic resin, polyether surfactant, isopropanol, purified water, marshmallow flower extract and additives are prepared according to weight percentage;

[0039] 2) Stirring pre-dispersion: Put the above-mentioned water-soluble toner, water-soluble acrylic resin, polyether surfactant, isopropanol and 50-80% pure water into the beating pot for high-speed pre-dispersion;

[0040] 3) Grinding and fine dispersion: Send the dispersed materials into the sand mill for sand grinding and dispersion. When the fineness of the materials is lower than 15 μm, send the materials into the ink mixing pot;

[0041] 4) Adjust the ink: Add the above-mentioned hollyhock flower extract, additives and the remaining purified water, and mix evenly to obtain the product.

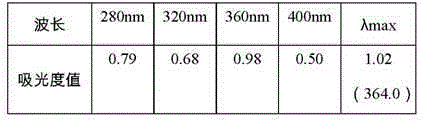

[0042] The extract of hol...

Embodiment 1

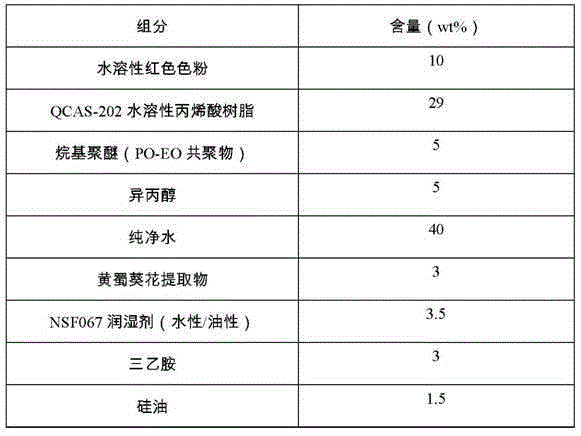

[0055] Raw materials: the weight percentage of specific components is shown in Table 3.

[0056] The composition of the aqueous ink of table 3 embodiment 1

[0057]

[0058] Preparation process: Water-soluble red toner, water-soluble acrylic resin, polyether surfactant, isopropanol, triethylamine, silicone oil defoamer and two-thirds of pure water prepared according to the above formula ratio are put into beating In the pot, beat at a high speed for 30-60 minutes below 45°C for pre-dispersion, and then send the dispersed material into the sand mill for sand-mill dispersion through the delivery pump. During sand-milling, the temperature of the material is kept at 45°C Next, when the fineness of the material is lower than 15 μm, the material will flow into the ink mixing pot, add hollyhock flower extract, NSF067 wetting agent (water-based / oil-based), and the remaining one-third of pure water for further processing Mix until uniform, adjust the ink until the inspection index ...

Embodiment 2

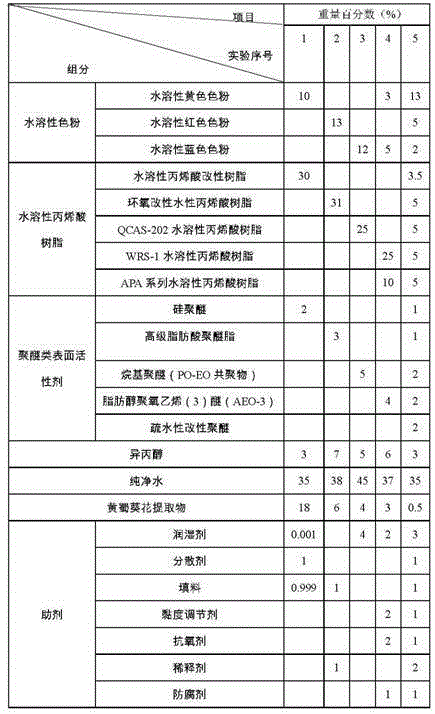

[0059] Example 2 With the weight percent batching of each component shown in table 4:

[0060] The composition of the aqueous ink of table 4 embodiment 2

[0061]

[0062] For the preparation process, refer to the preparation process of Example 1.

[0063] The light fastness of the ink (non-decolorization) is measured by a professional measurement method for printed matter and printing ink. The principle is: under the specified conditions, the test sample and the blue wool standard sample are exposed to the xenon arc lamp at the same time, and the light fastness is evaluated by finding a level similar to the test sample in the blue wool standard sample. Under the condition that other formulas remain unchanged, the lightfastness of the non-discoloration water-based ink added with hollyhock flower extract is 1-3 grades higher than that of the water-based ink without hollyhock flower extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com