Frame beam composite reinforcing method by transversely tensioning prestress carbon fiber cloth and steel

A carbon fiber cloth, transverse tensioning technology, applied in the direction of building maintenance, construction, building construction, etc., can solve the problems of reducing the efficiency of tensioning construction, complex composition of prestressed tensioning system, etc., to achieve multi-effect utilization, improve anchorage Reliability, clever and rational use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

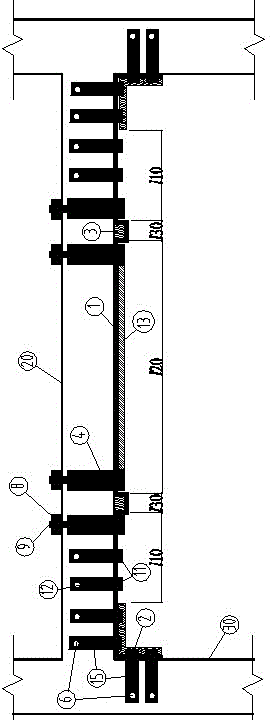

[0036] Embodiment one: if figure 1 , figure 2 and image 3 As shown, the method for compositely strengthening frame beams of transversely tensioned prestressed carbon fiber cloth and steel of the present invention comprises the following specific steps:

[0037] (A) Paste and fix both ends of the carbon fiber sheet 1 to the L-shaped steel anchor plate 2 , and then install and fix the L-shaped steel anchor plate 2 to the angle between the lower surface of the frame beam 20 and the inner surface of the frame column 30 .

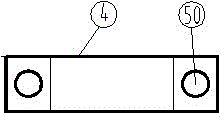

[0038] (B) Pull the carbon fiber sheet 1 horizontally downwards, insert at least two steel backing plates 3 between the upper surface of the carbon fiber sheet 1 and the lower surface of the frame beam 20, and bond and fix the upper surface of the steel backing plate 3 on the lower surface of the frame beam 20;

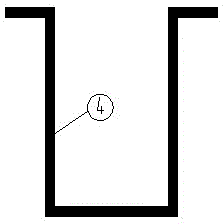

[0039] (C), symmetrically arrange a U-shaped steel plate 4 with the opening facing up on both sides of each steel backing plate 3, and pull the U-...

Embodiment 2

[0058] Embodiment two: if Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the upper part of the frame beam 20 is provided with a floor slab 40, which requires drilling holes on the bottom of the floor slab 40 on both sides of the frame beam 20 to pre-embed the second fastening bolt 10, The second fastening bolt 10 is connected with the U-shaped steel plate 4 to tension the carbon fiber sheet 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com