Patents

Literature

50results about How to "Play a role in stretching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

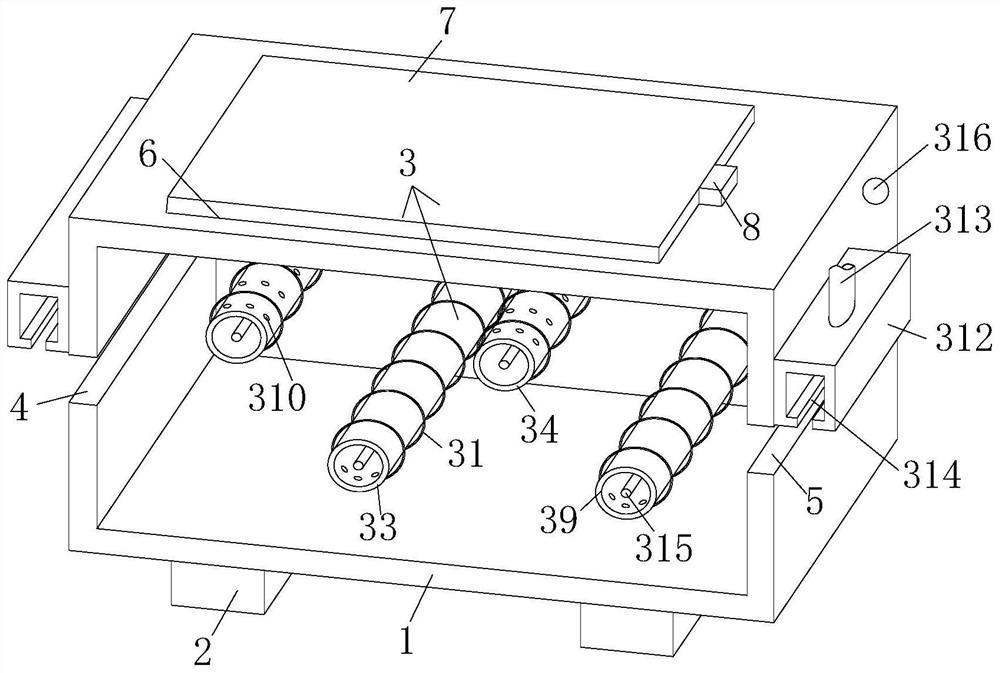

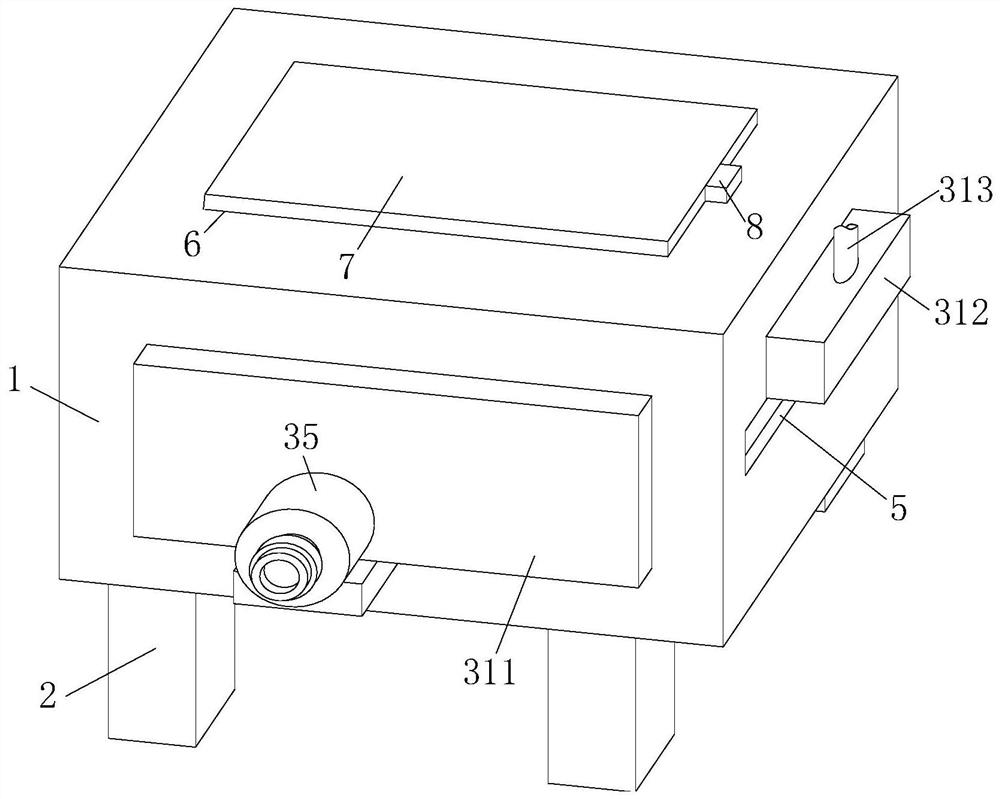

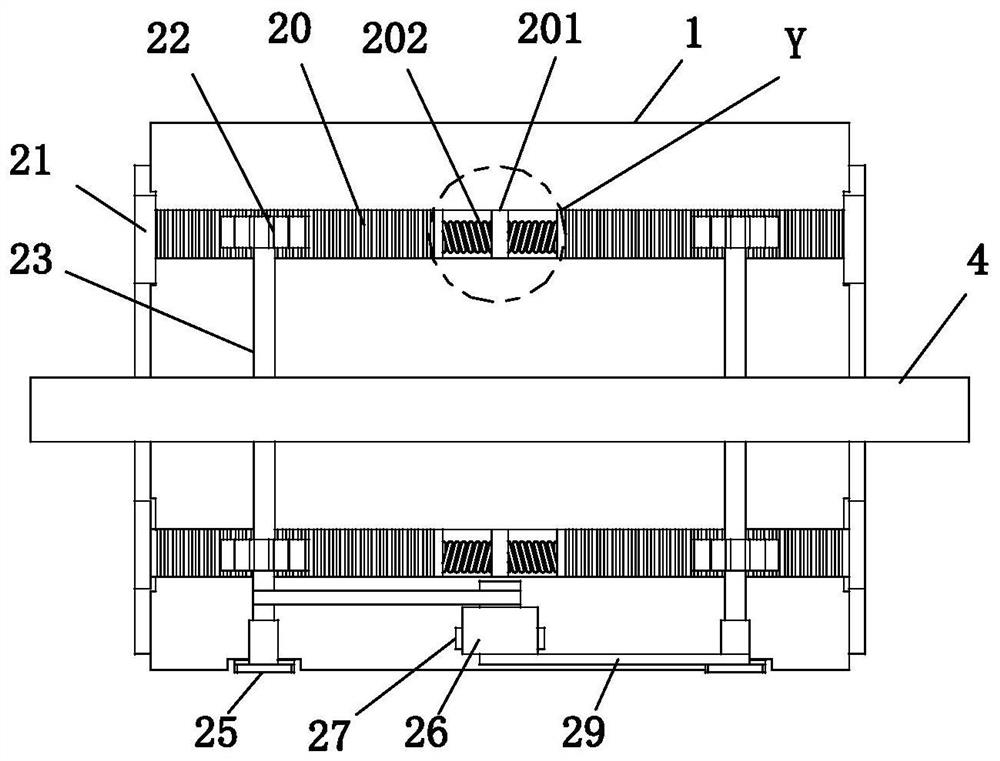

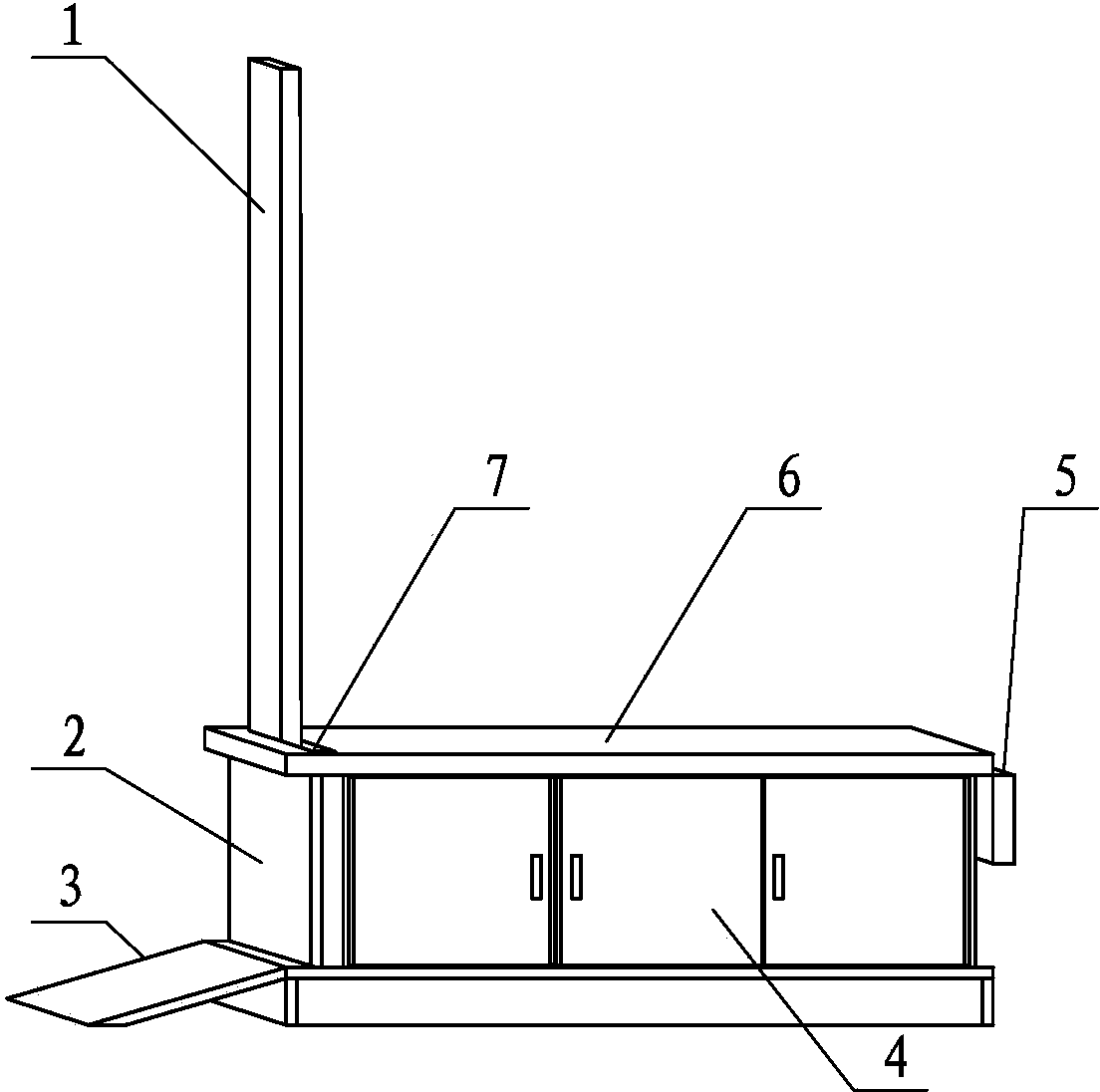

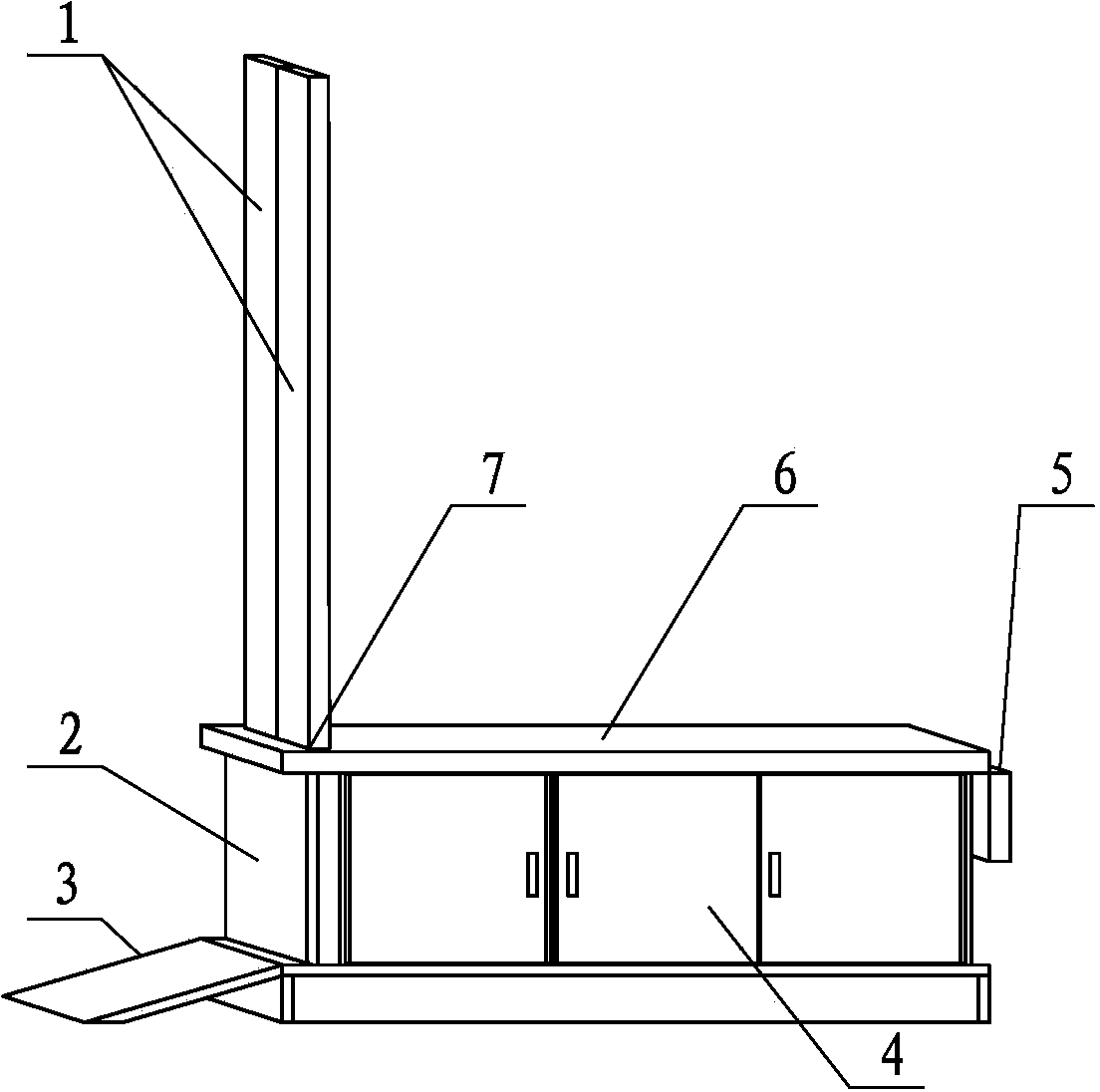

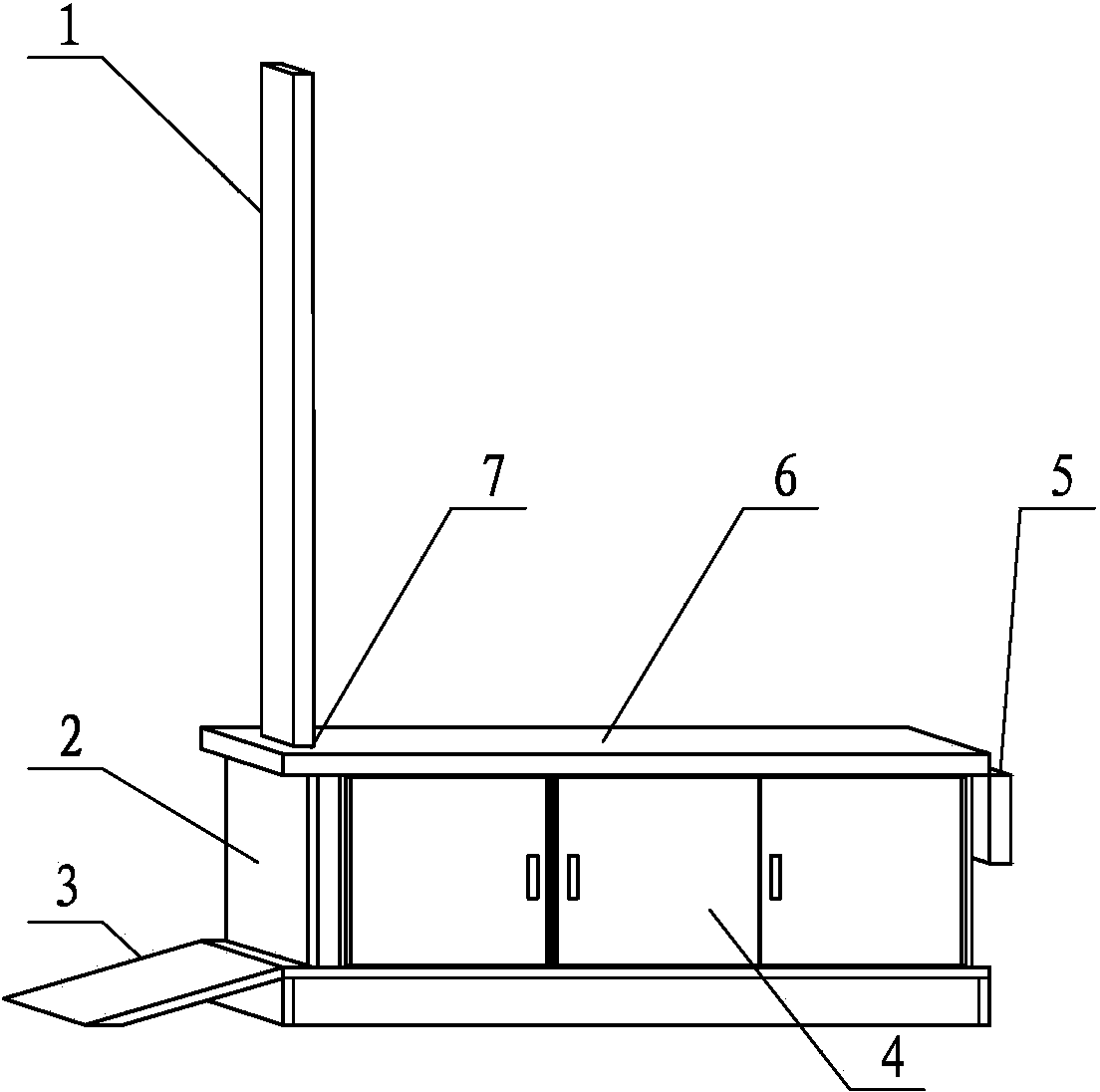

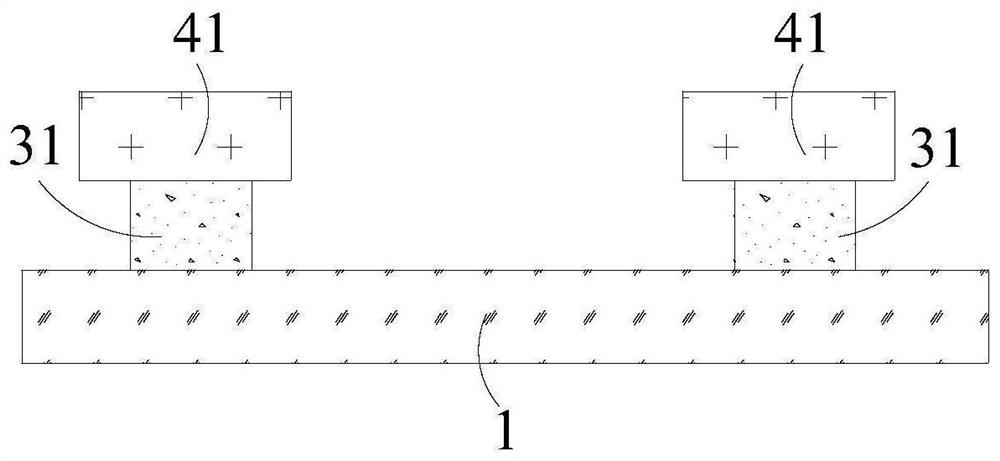

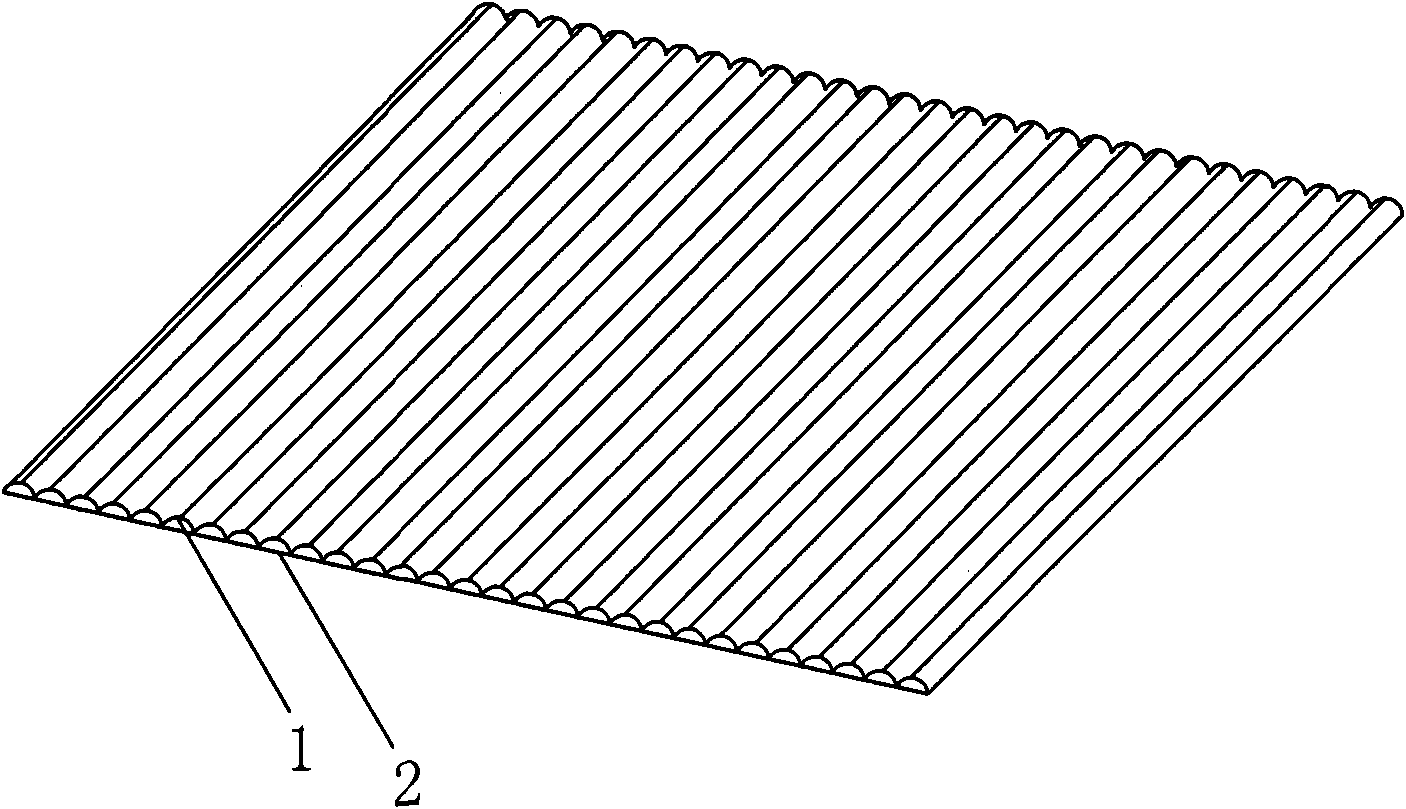

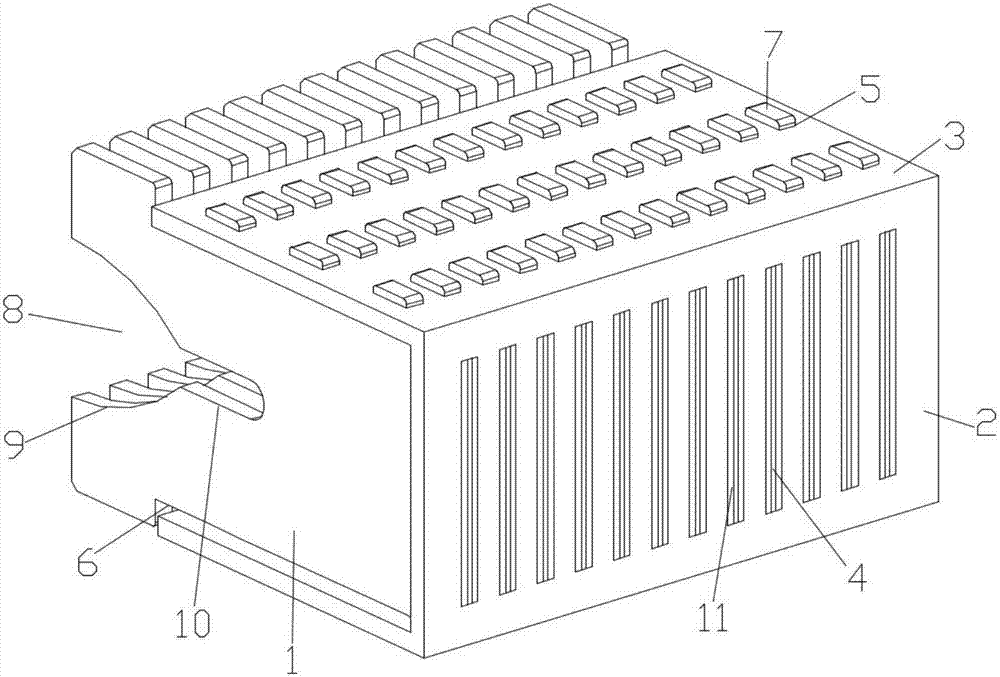

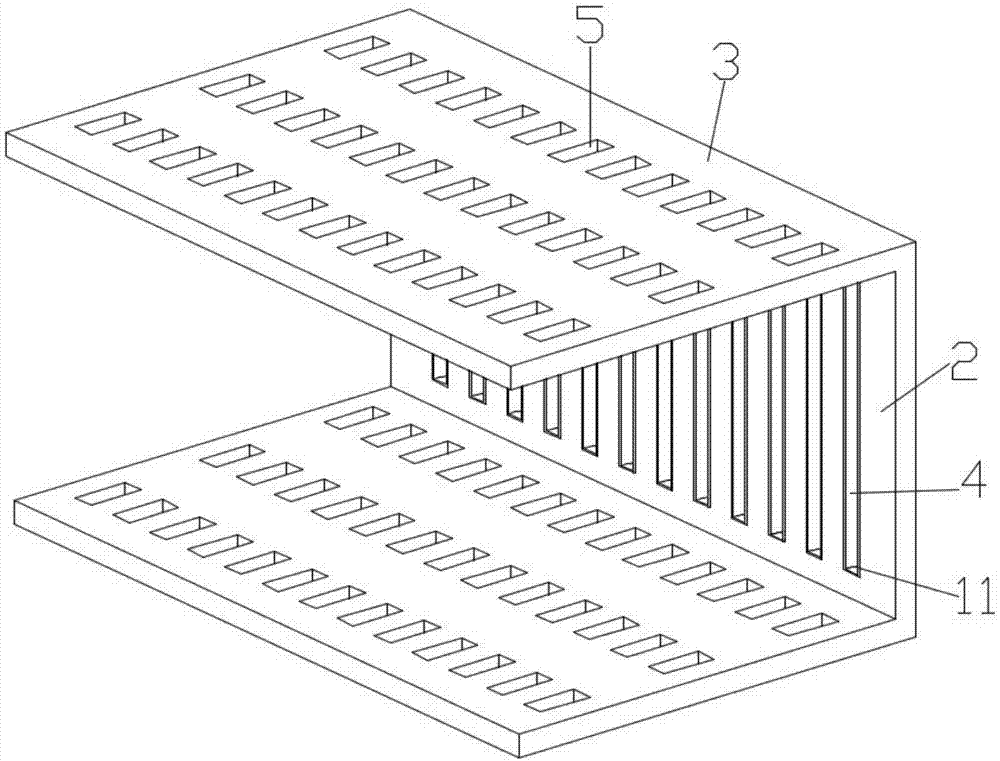

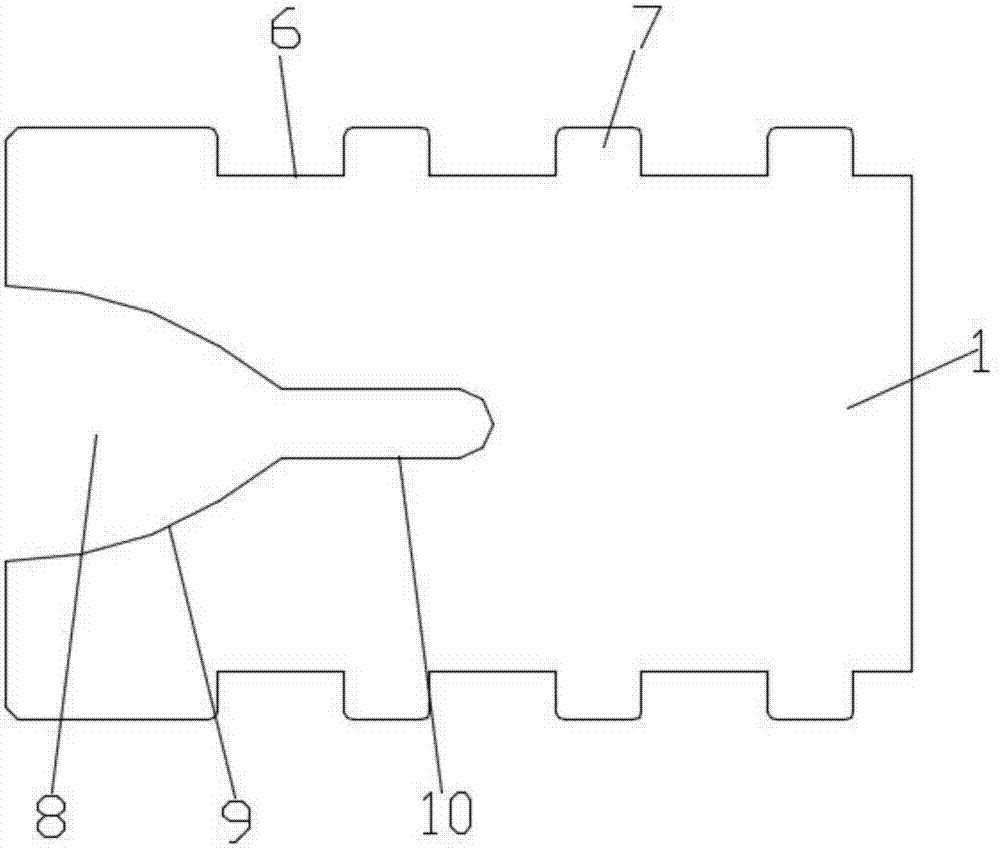

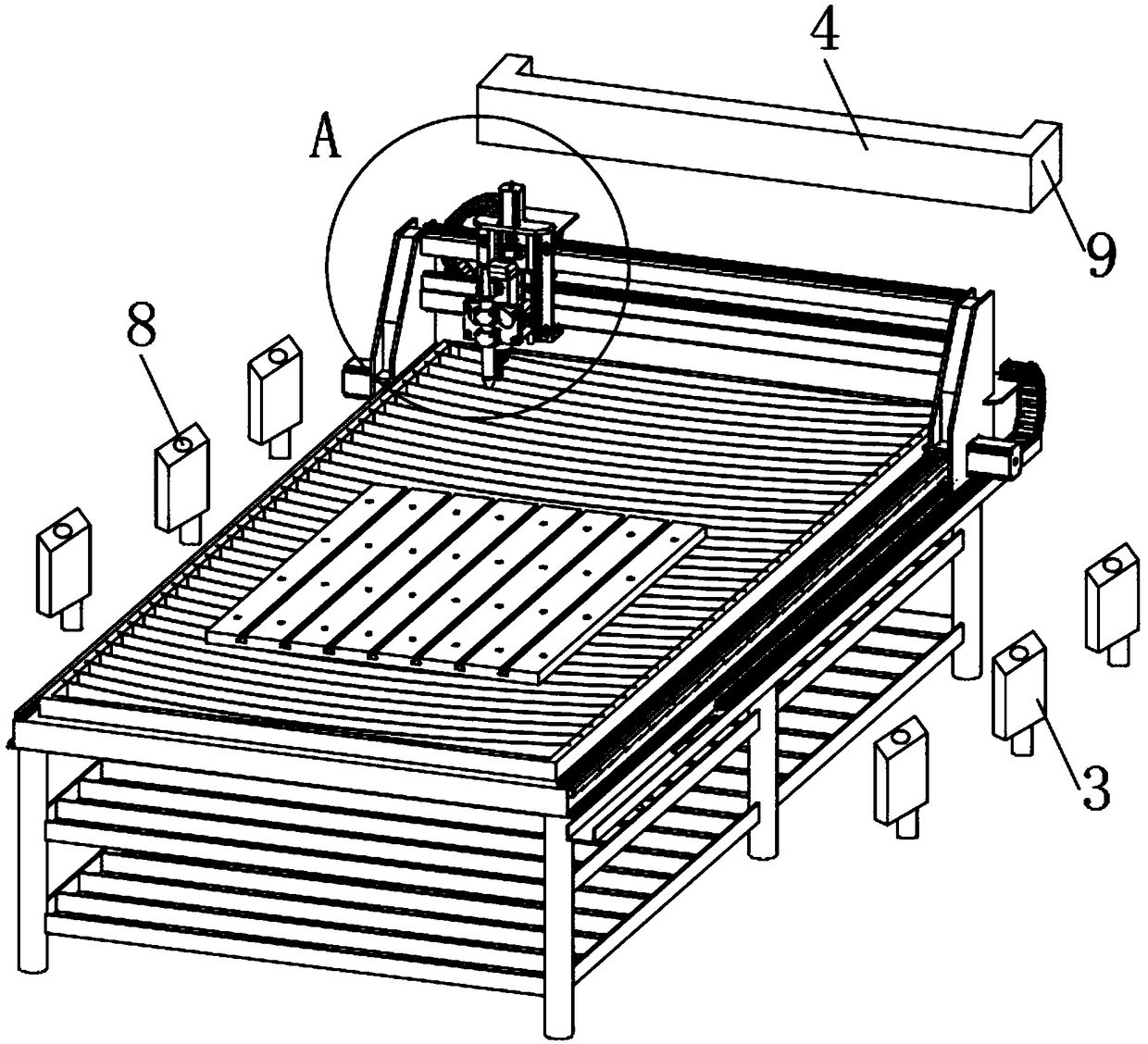

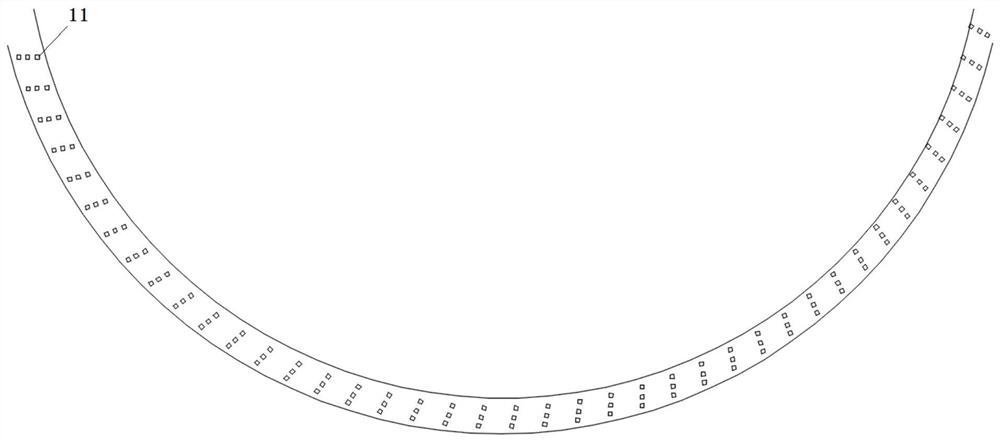

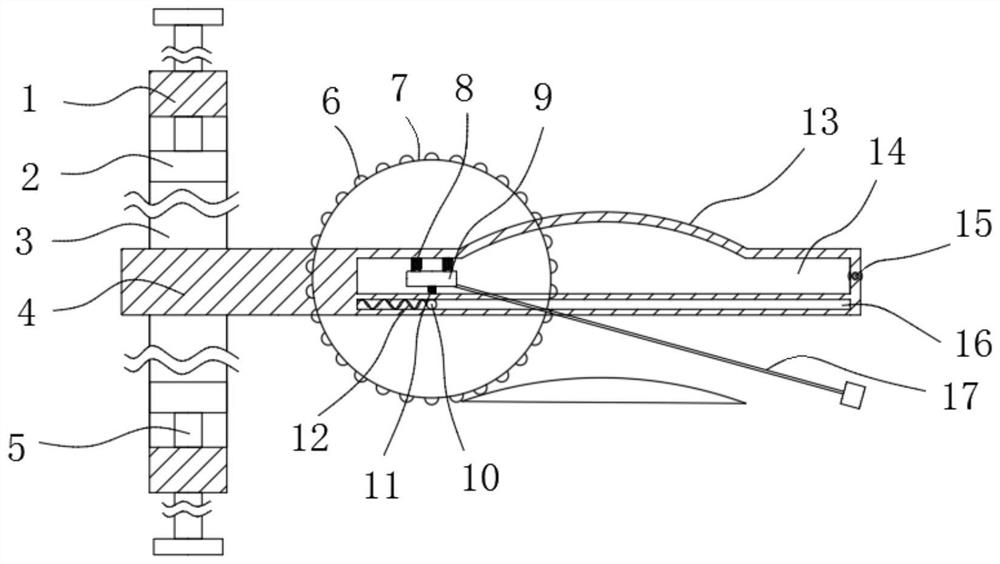

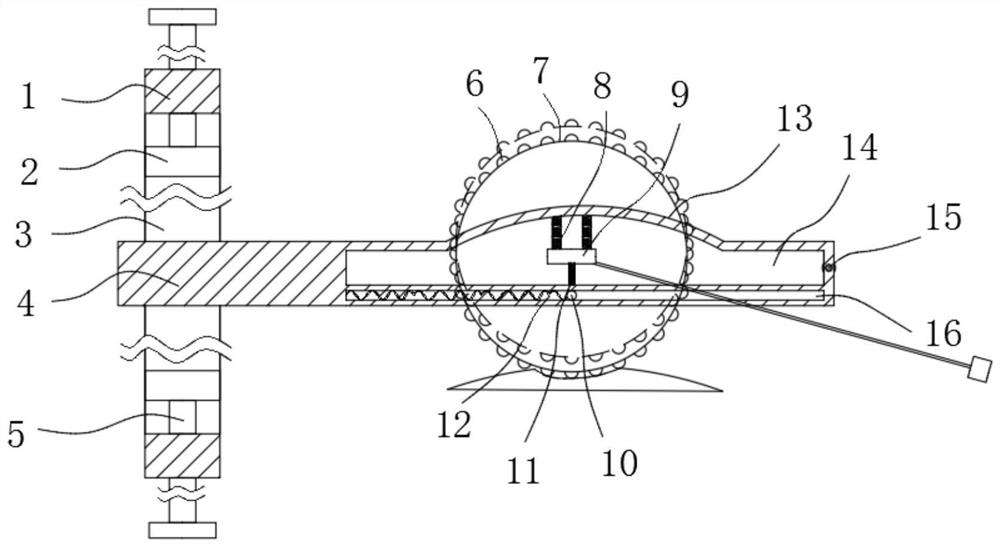

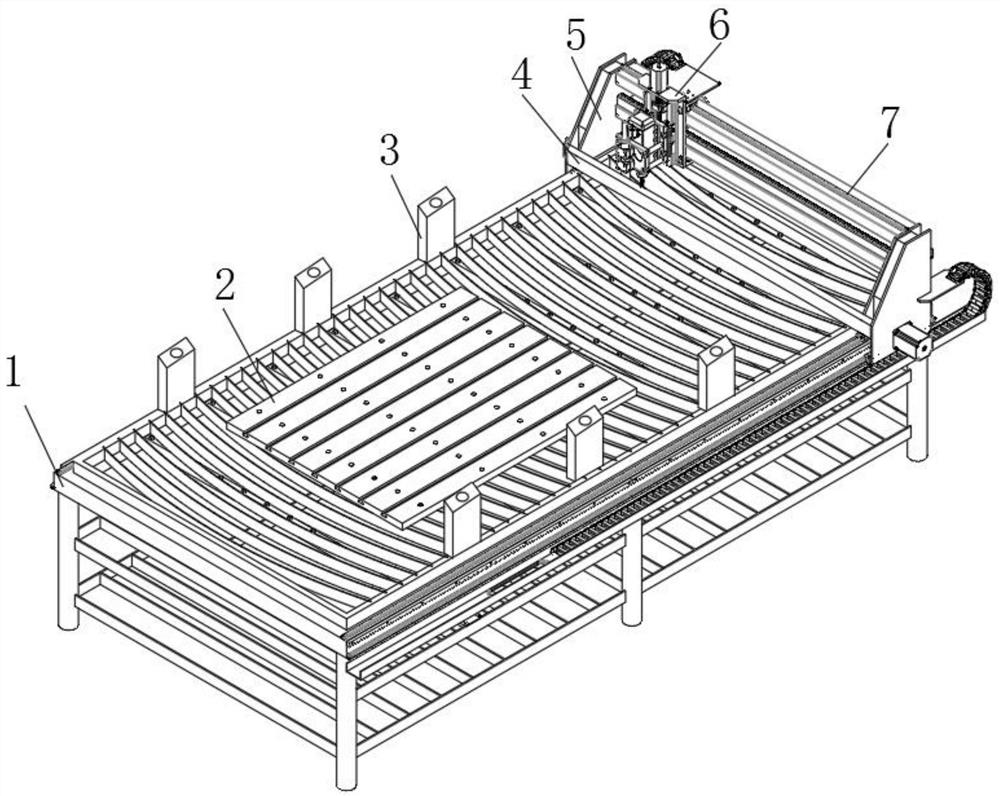

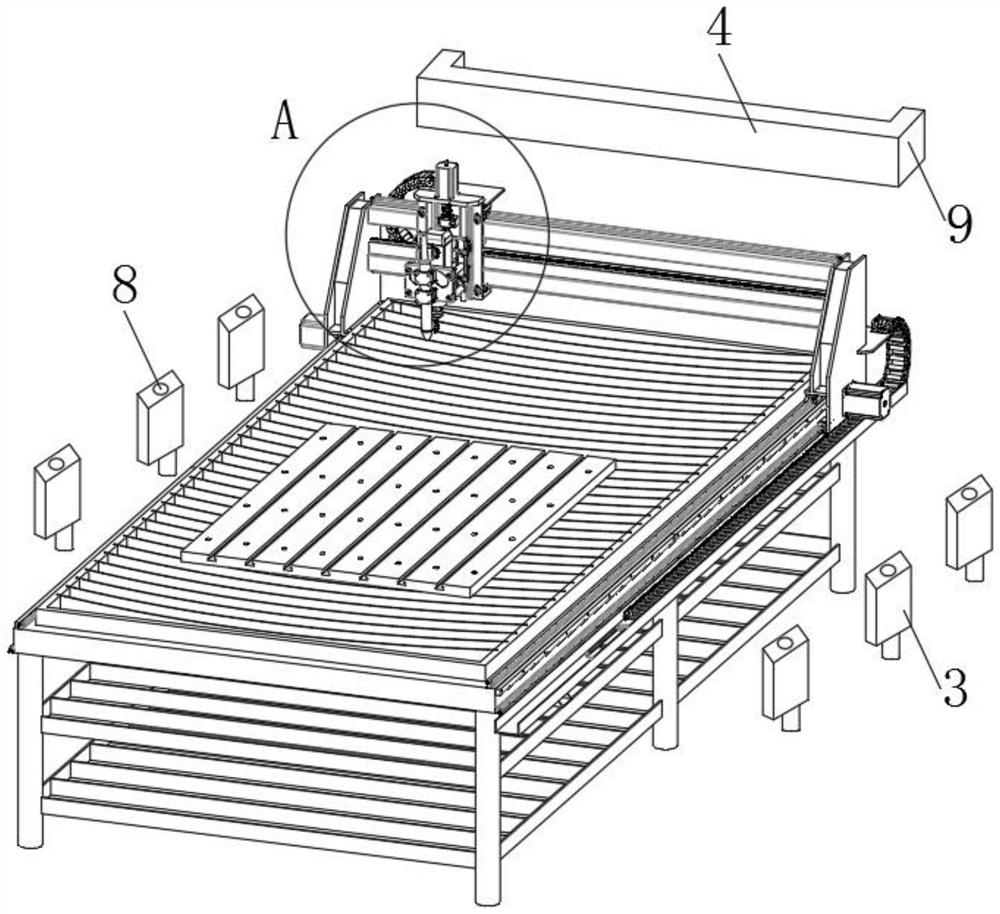

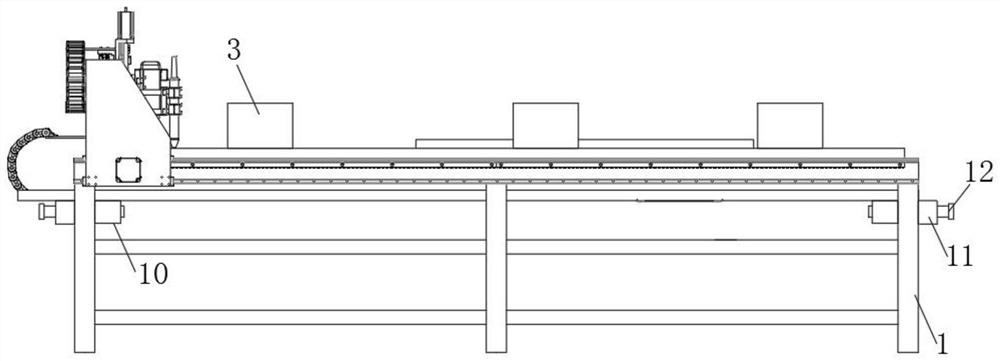

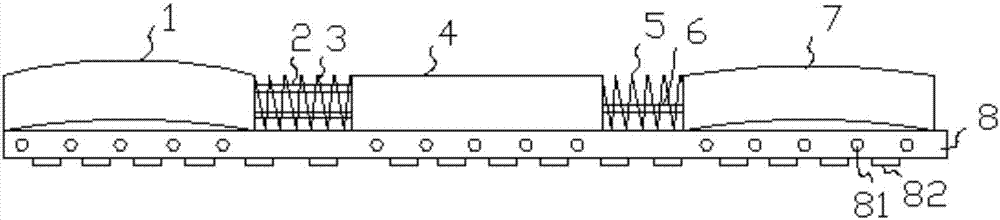

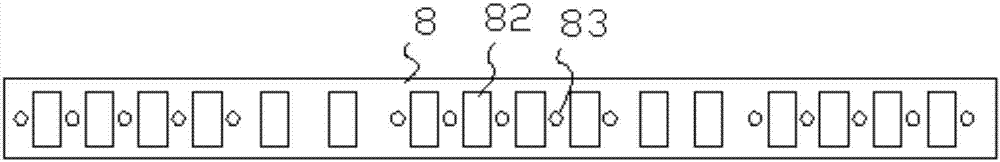

Cloth starching and sizing integration device

InactiveCN105714499AReduce manufacturing costUniform conjunctivaSucessive textile treatmentsLiquid/gas/vapor removalSlurryPulp and paper industry

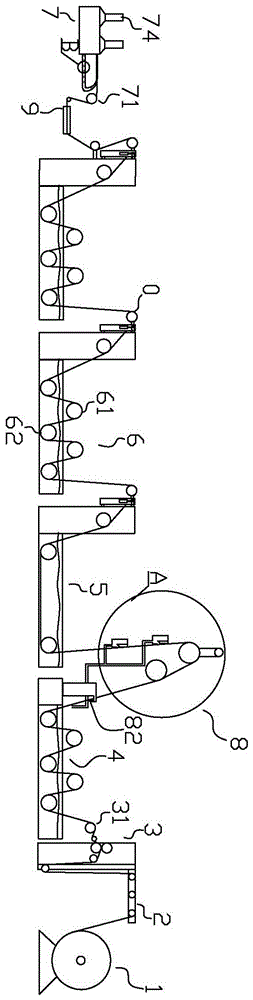

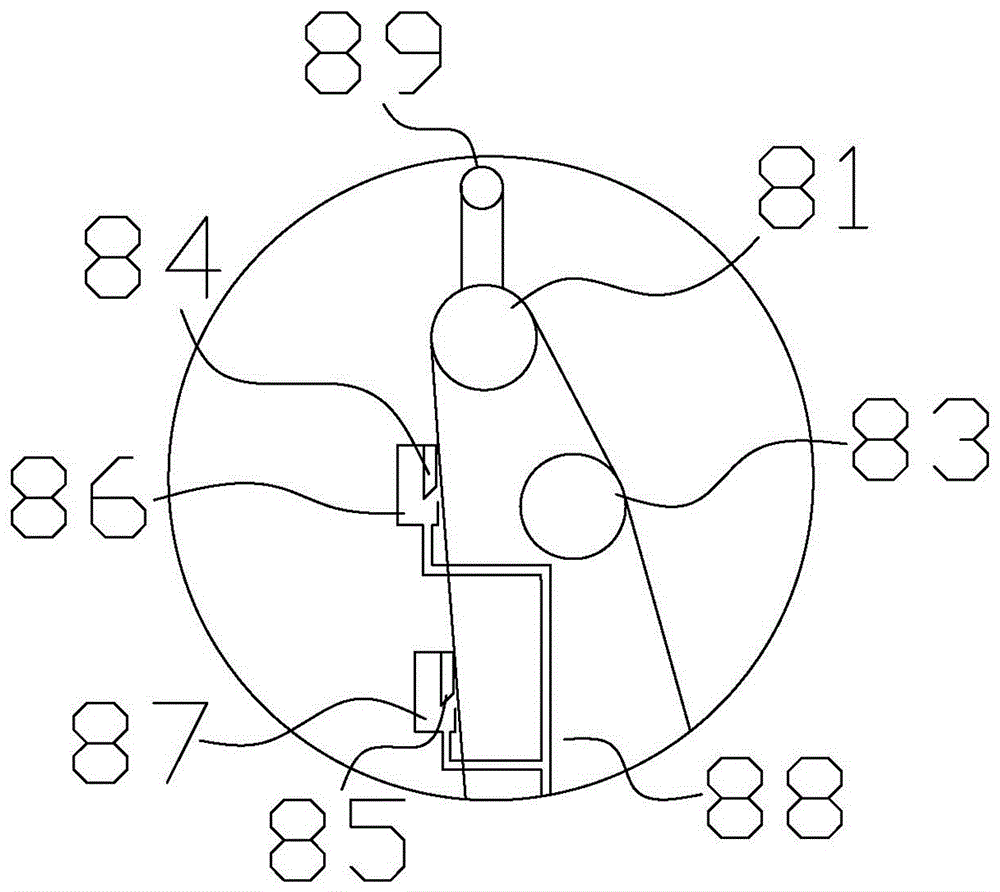

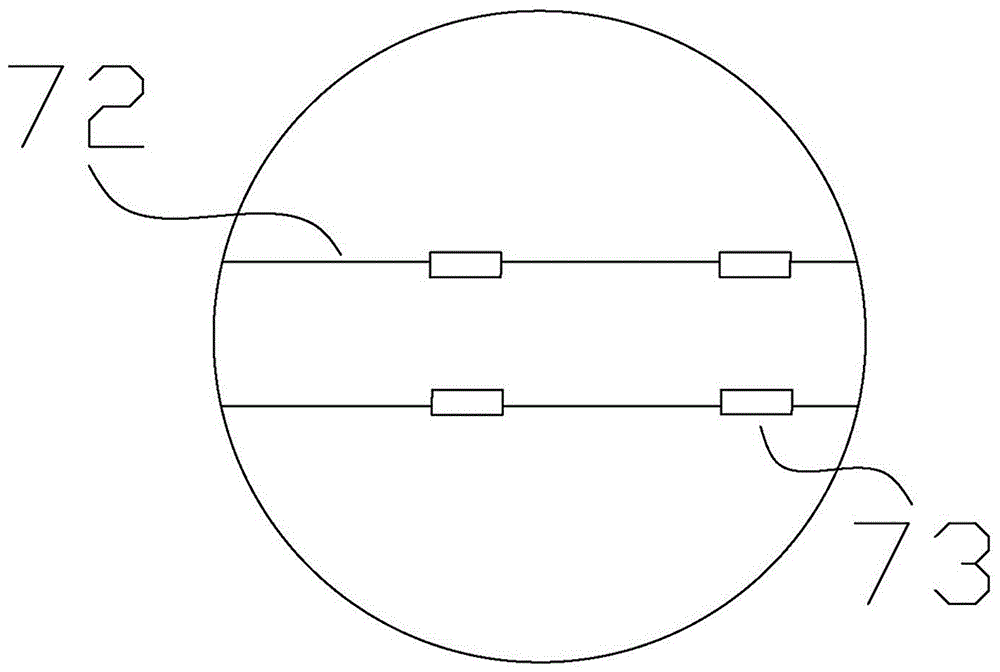

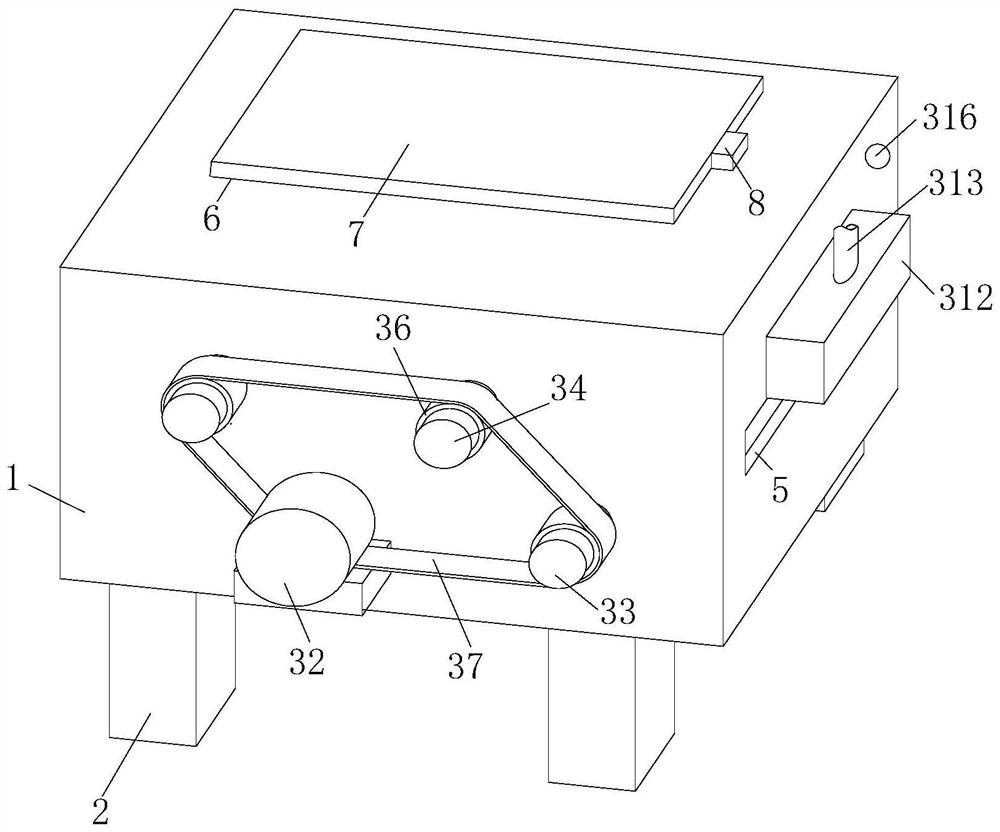

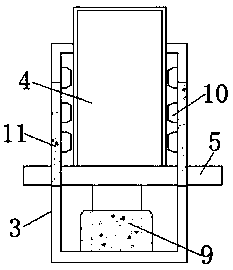

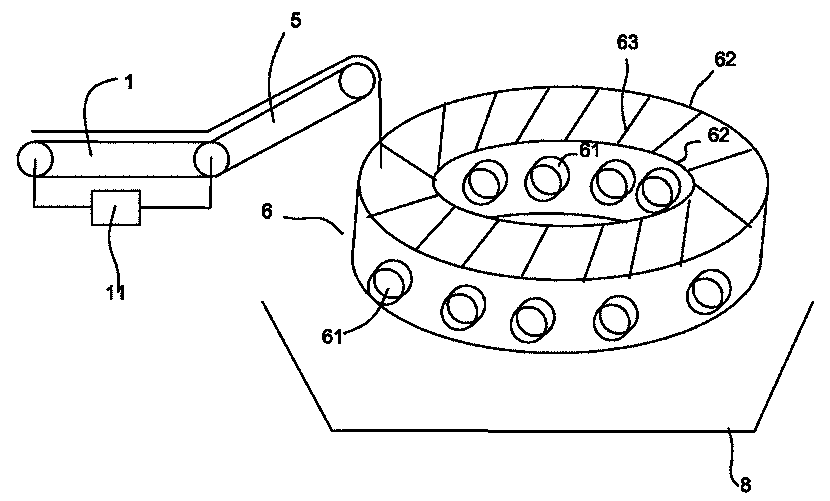

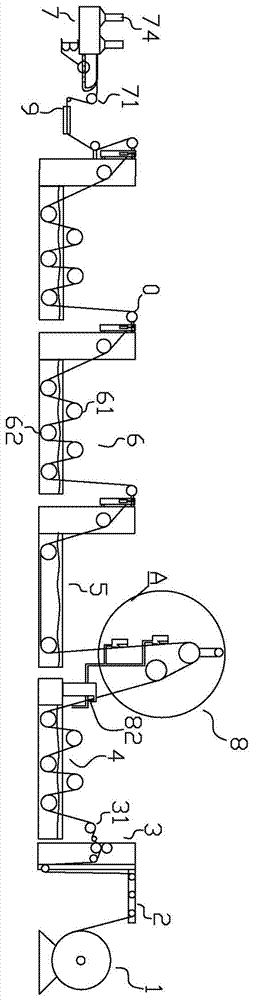

The invention relates to a cloth starching and sizing integration device, and belongs to the technical field of label cloth production. The cloth starching and sizing integration device sequentially comprises a cloth feeding device, a cloth feeding padder, a cloth feeding stretching device, a slurry pool, a film forming pool, a washing pool and a drying device, wherein a scraping recovery device is arranged between the cloth feeding stretching device and the slurry pool and comprises a rectifier roll of which the position is higher than the slurry pool; the cloth is stretched and moved among the rectifier roll, the slurry pool and the film forming pool; a coarse scraper is arranged on the cloth surface between the rectifier roll and the slurry pool; an auxiliary rectifier roll is arranged at the lower part of the rectifier roller; and a scraper, a fine scraper, a first slurry collecting tank and a second slurry collecting tank are sequentially arranged between the rectifier roll and the film forming pool. According to the cloth starching and sizing integration device, the slurry is saved; and starching is even.

Owner:HUZHOU CHANGSHENG BELT IND CO LTD

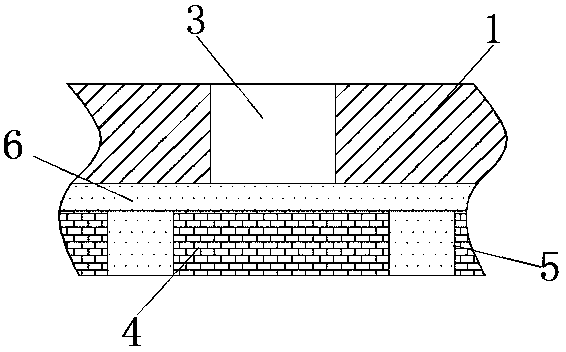

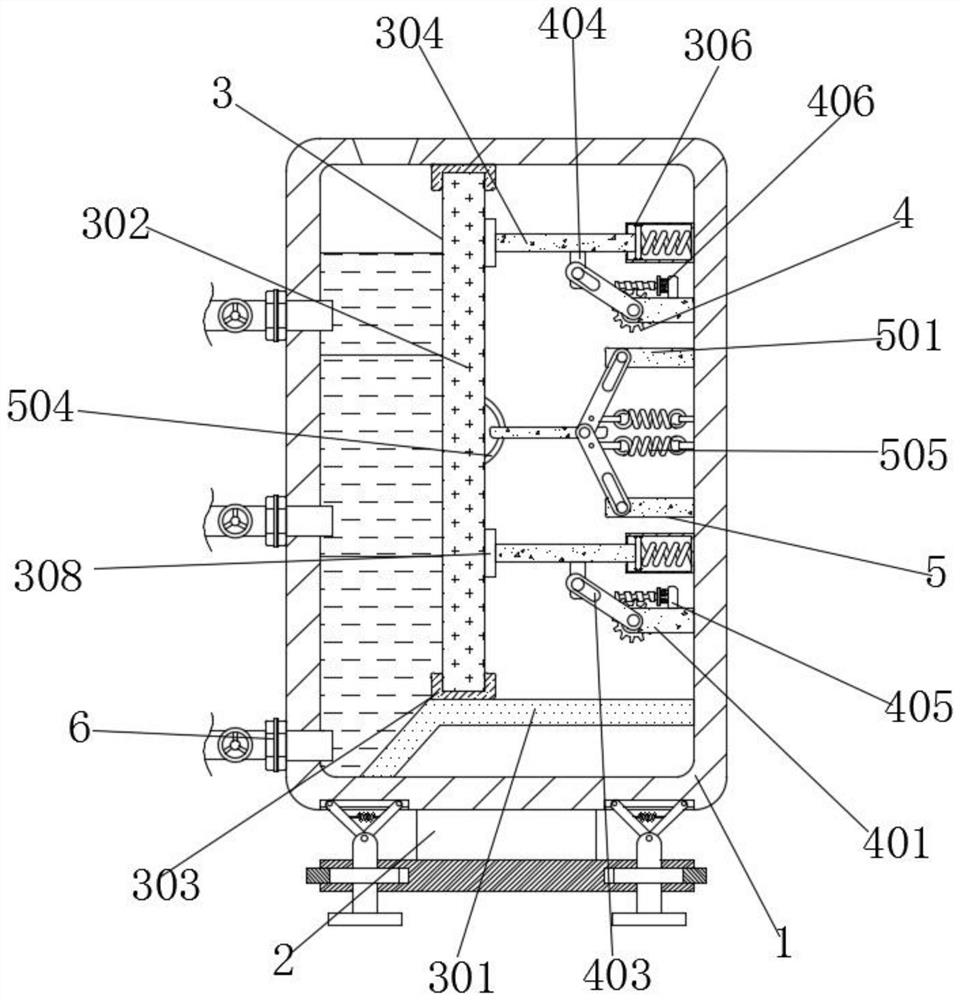

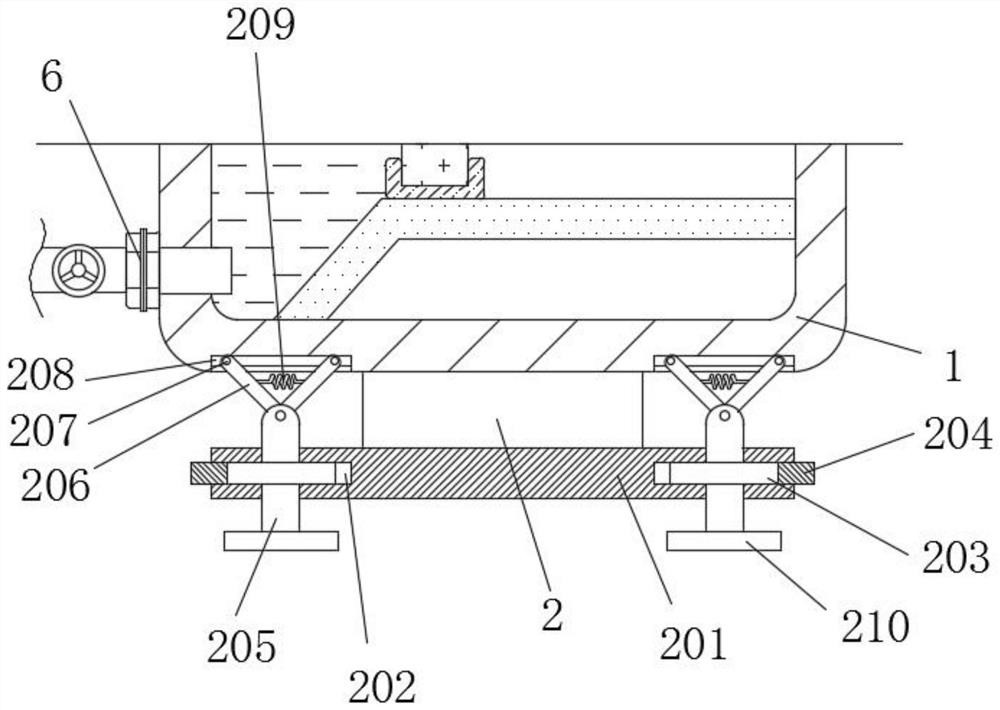

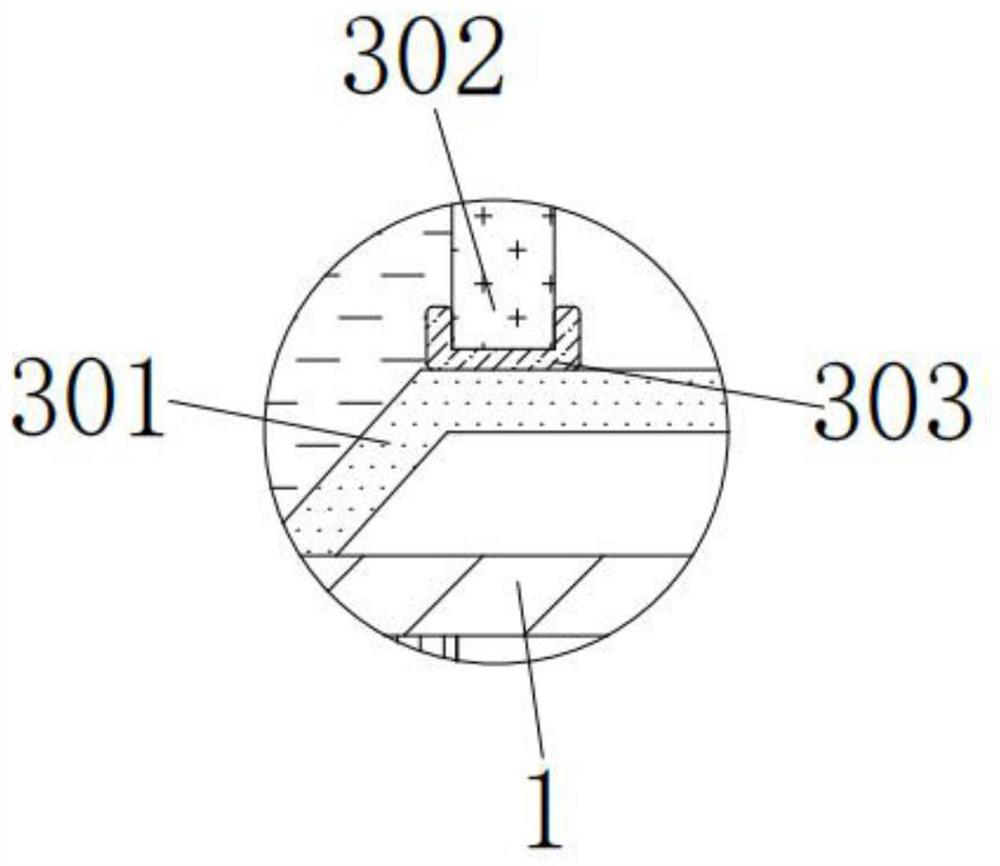

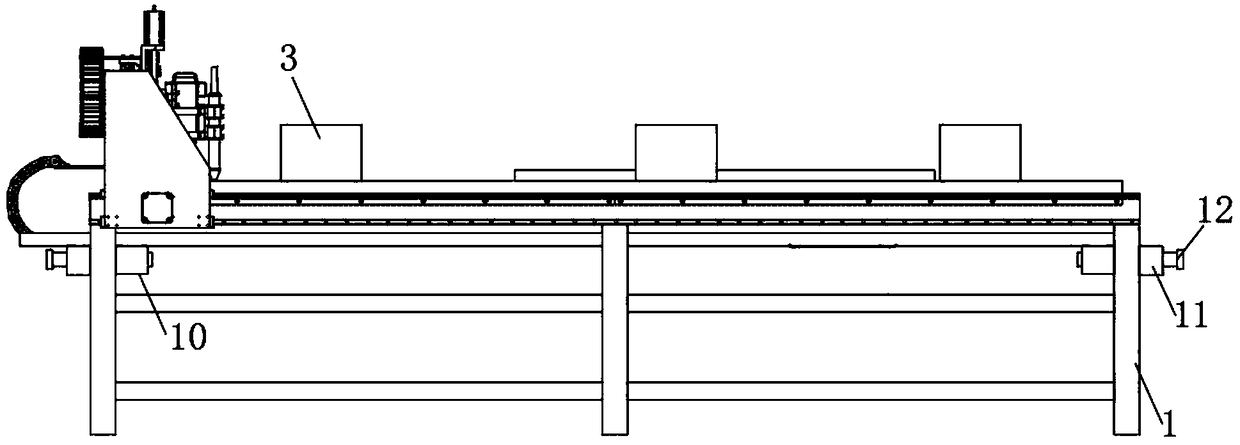

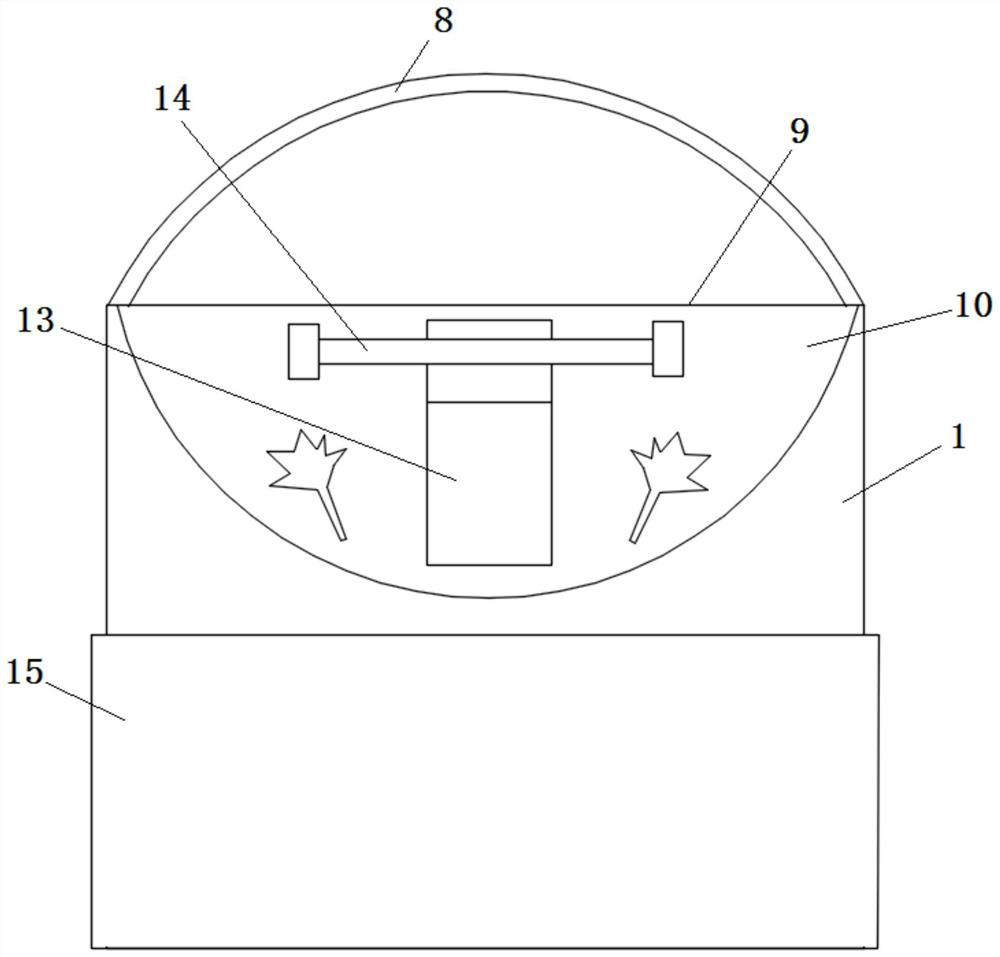

Elastic drying device for textile processing

InactiveCN111947432AEasy to dryNo disorderDrying gas arrangementsDrying machines with progressive movementsDrying timeMechanical engineering

The elastic drying device comprises a drying box body for drying cloth in the conveying process, supporting legs for supporting the drying box body and an adsorption type movable drying mechanism foradsorbing and drying the cloth in the box body; a feeding opening is formed in the surface of the drying box body; and a discharging opening is formed in the surface of the drying box body. The invention relates to the field of textile processing. According to the elastic drying device for textile processing, the special drying structure capable of avoiding disorder of the cloth in the narrow andsmall space and promoting circulation of people is designed according to the high wind disorder condition and the problem of high energy consumption in the drying process of the cloth, and the problems that when the cloth is dried by common textile drying devices, conveying disorder of the cloth is caused easily by the excessively high wind power, the situation that the cloth is not dried thoroughly is caused easily by the excessively low wind power, the conveying speed is required to be reduced and the drying time is required to be prolonged to a certain extent, and the processing efficiencyis affected are solved. The invention provides an elastic drying device for textile processing.

Owner:胡长凤

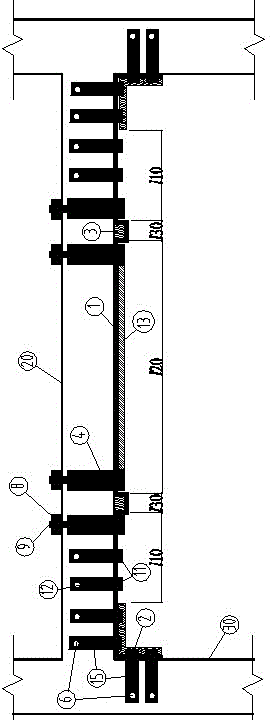

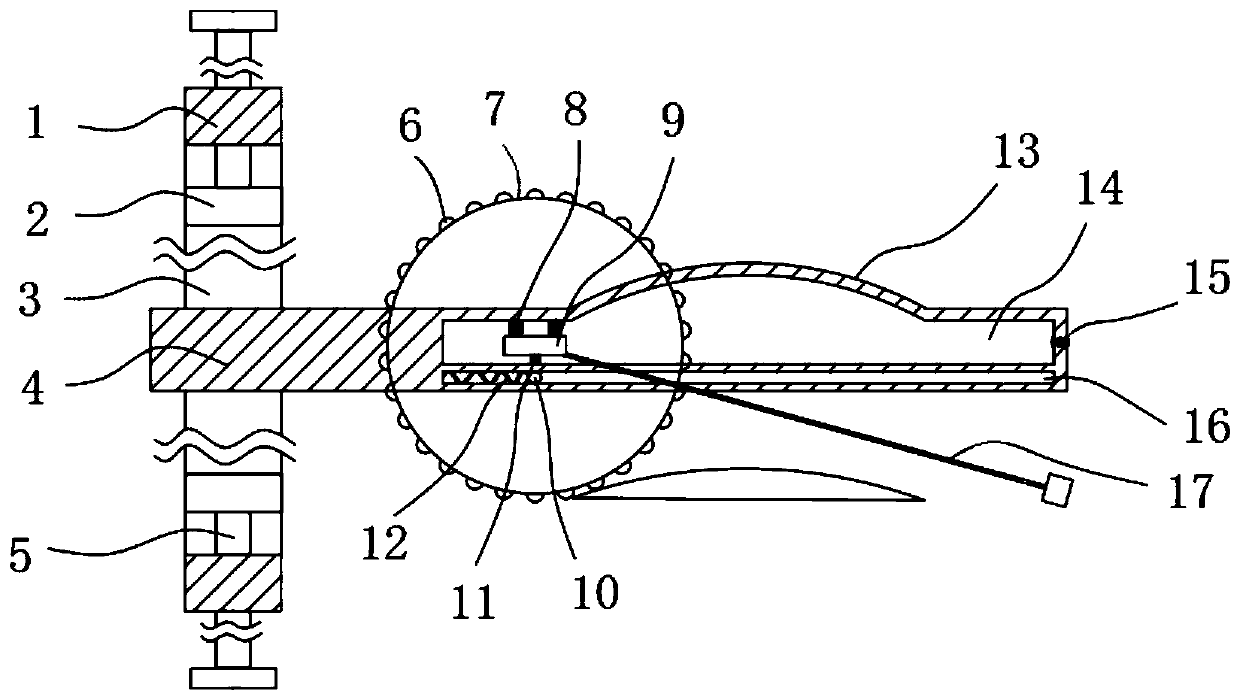

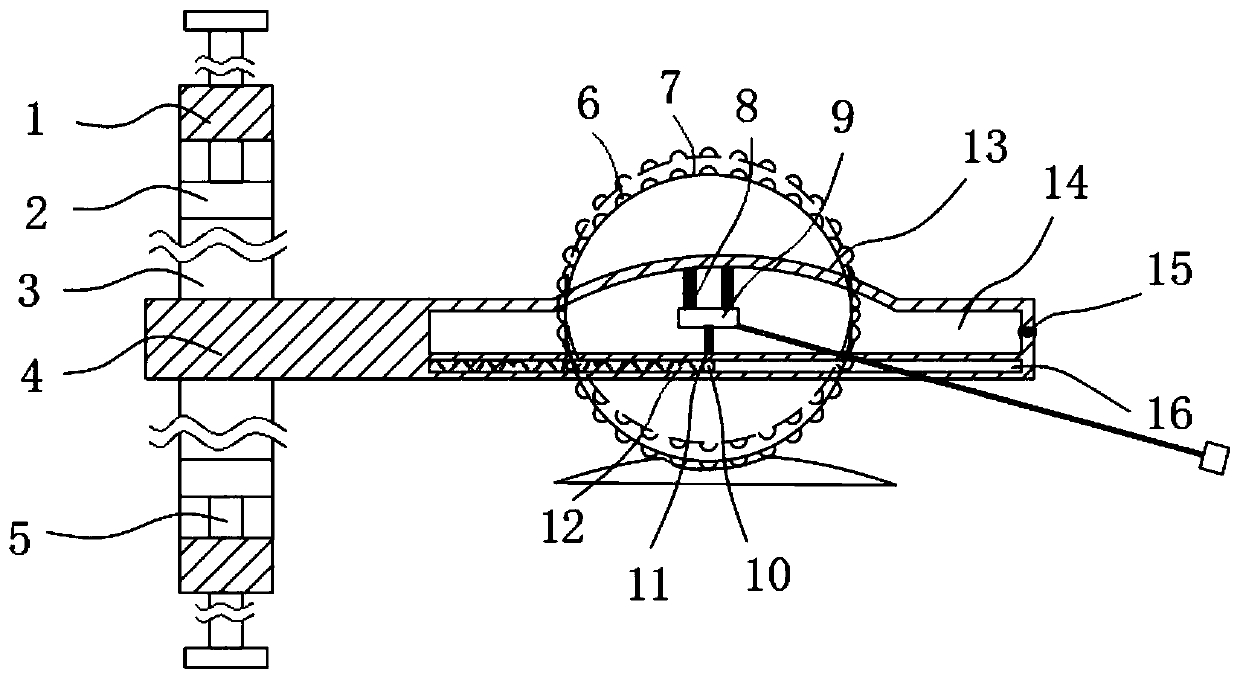

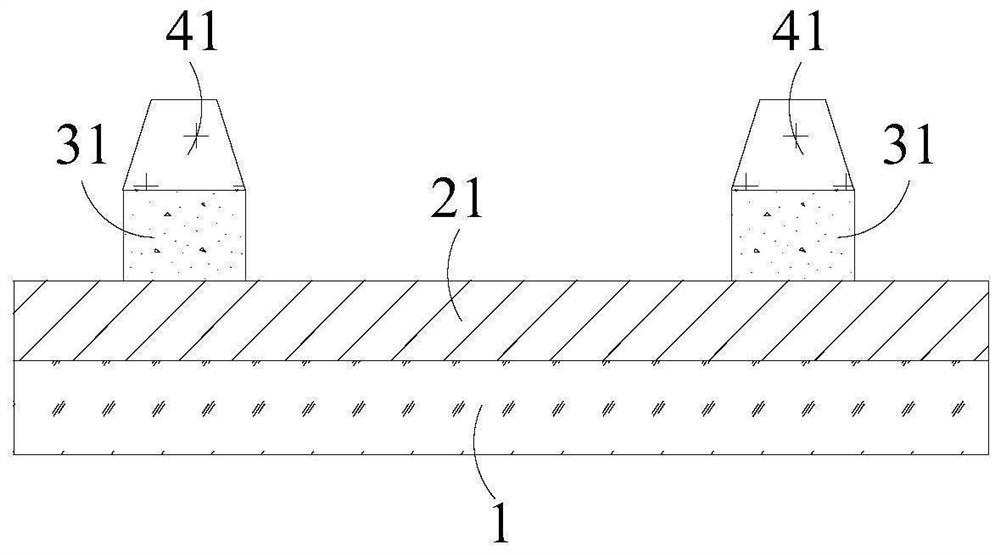

Frame beam composite reinforcing method by transversely tensioning prestress carbon fiber cloth and steel

ActiveCN103912132AImprove end anchorage reliabilityPlay a role in stretchingBuilding repairsFiberCarbon fibers

The invention relates to a frame beam composite reinforcing method by transversely tensioning prestress carbon fiber cloth and steel. The method includes: adhering and fixing two ends of a carbon fiber sheet to an L-shaped steel anchor plate, and mounting the anchor plate with the carbon fiber sheet to two ends of a frame beam; transversely downwardly tensioning the carbon fiber sheet, filling in a steel base plate, and adhering and fixing the steel base plate on the frame beam; using a U-shaped steel plate for synchronously, symmetrically, transversely and upwardly tensioning the carbon fiber sheet for once or multiple times, and fixing the U-shaped steel plate on the frame beam after the carbon fiber sheet is closes attached to the bottom of the frame beam; adhering a steal plate at the bottom of the beam with U-shaped steel hoops in sections at two ends, and anchoring through chemical anchor bolts. By the method, reliable tensioning anchoring and zero-gap adhering can be achieved easily, the high strength performance of the carbon fiber sheet is utilized to apply high-level prestress to the frame beam, the anti-shear bearing capacity of the frame beam is increased by comprehensively using a tensioning anchoring steel plate, the performances of the carbon fiber sheet and steel are brought into full play, and anti-bending and anti-shear bearing force synergetic reinforcement of the frame beam is achieved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

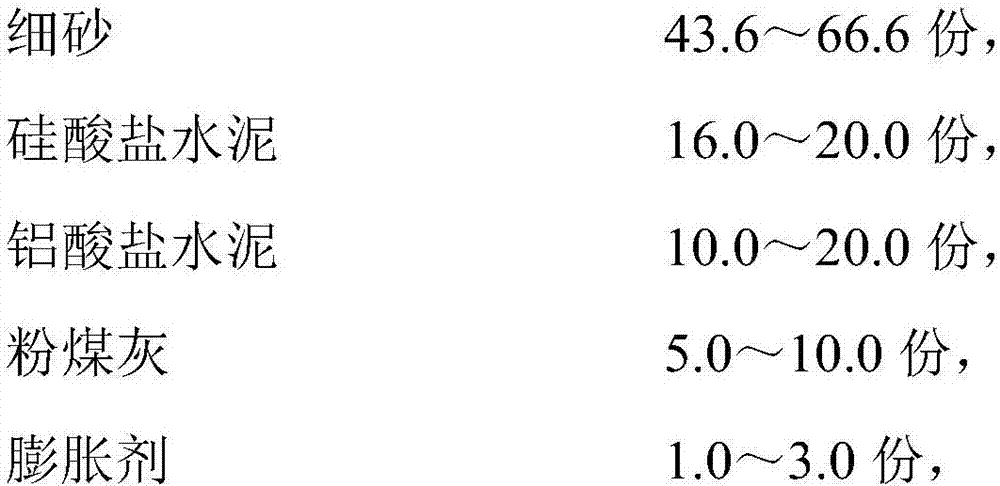

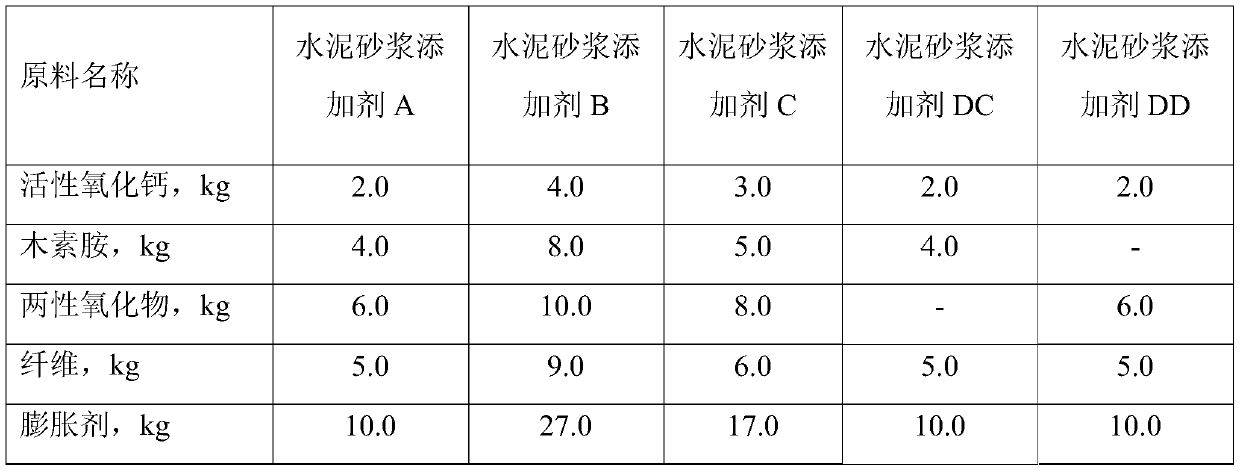

Cement mortar dry powder as well as preparation method and application thereof

The invention discloses cement mortar dry powder as well as a preparation method and application thereof. The cement mortar dry powder comprises fine sand, Portland cement, aluminate cement, coal ash, an expanding agent, fibers, amphoteric oxides, lignin amine and active calcium oxide. When being used, the cement mortar dry powder disclosed by the invention is uniformly mixed with water, and then cement mortar is made. The cement mortar dry powder disclosed by the invention has the characteristics of high early strength, controllability, no cracking, no whiskering and the like, in addition is low in preparation cost, and can not only meet management of sewer wells of city streets and rapid repairing of airfield runways, cement pavements, tunnels and the like, but also meet rapid construction requirements of back grouting of equipment foundation and reinforcement of foundation bolts.

Owner:辽宁兆利高新路面材料有限公司

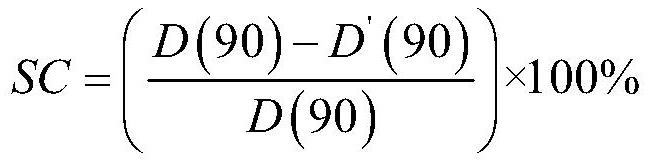

Dyeing and finishing method of fiber fabric containing PLA and PHBV

ActiveCN104499306AUniform dyeingGood shaping effectSucessive textile treatmentsBiochemical fibre treatmentChemistryEnzyme

The invention discloses a dyeing and finishing method of a fiber fabric containing PLA and PHBV. The dyeing and finishing method comprises the following steps: sewing blank cloth; desizing; tentering; drying; shaping; dyeing; and carrying out post-treatment; particularly, desizing, namely putting the blank cloth into a penetrating agent solution with the concentration being 3.5g / L-4.5g / L; padding in an enzyme solution with the enzyme concentration being 0.6g / L-1.2g / L; dyeing, namely by utilizing disperse dyes, controlling the temperature by phases; in the first phase, continually raising the temperature at 35-55 DEG C at the speed of 2-2.5 DEG C / min; in the second phase, continually raising the temperature at 55-85 DEG C at the speed of 1-1.5 DEG C / min, and keeping the temperature for 8-15 minutes after the temperature is raised to 85 DEG C; in the third phase, continually raising the temperature at 85-100 DEG C at the speed of 0.5-1 DEG C / min, and keeping the temperature for 8-15 minutes after the temperature is raised to 100 DEG C; and in the fourth phase, cooling the temperature to 50 DEG C from 100 DEG C at the speed of 1-2 DEG C / min so as to finish the whole dyeing process. The dyeing and finishing method has the advantages of rapidness in coloring, uniform dyeing and uneasiness of de-coloring.

Owner:NINGBO XINDACHANG WEAVING

Sewer well treatment method and fast-setting cement mortar dry blend

ActiveCN103806524AHigh base strengthAvoid structural collapseSewerage structuresRoad surfaceCement mortar

The invention discloses a sewer well treatment method and a fast-setting cement mortar dry blend. The sewer well treatment method includes the steps of (1) carrying out cutting to form an annular zone around a sunk sewer well cover, and taking out the sewer well cover, (2) digging out basic layer materials of the annular zone, placing a prefabricated piece at an opening of a sewer well, placing the well cover on the prefabricated piece, and adjusting the horizontal position to enable the upper surface of the well cover to be flush with the road surface, and (3) pouring the annular zone dug out around the prefabricated piece with fast-setting cement mortar. According to the sewer well treatment method, the strength of a structure around the sewer well is improved, rainwater is prevented from permeating the sewer well, and the sinking problem of the urban sewer well can be effectively solved. The construction speed is high, and traffic is not influenced. The fast-setting cement mortar dry blend comprises cement, sand, expanding agents, water reducing agents, calcium oxide and the like. The sewer well treatment method and the fast-setting cement mortar dry blend are suitable for treating the sewer well of the cement road surface and the sewer well of the pitch road surface.

Owner:CHINA PETROLEUM & CHEM CORP +1

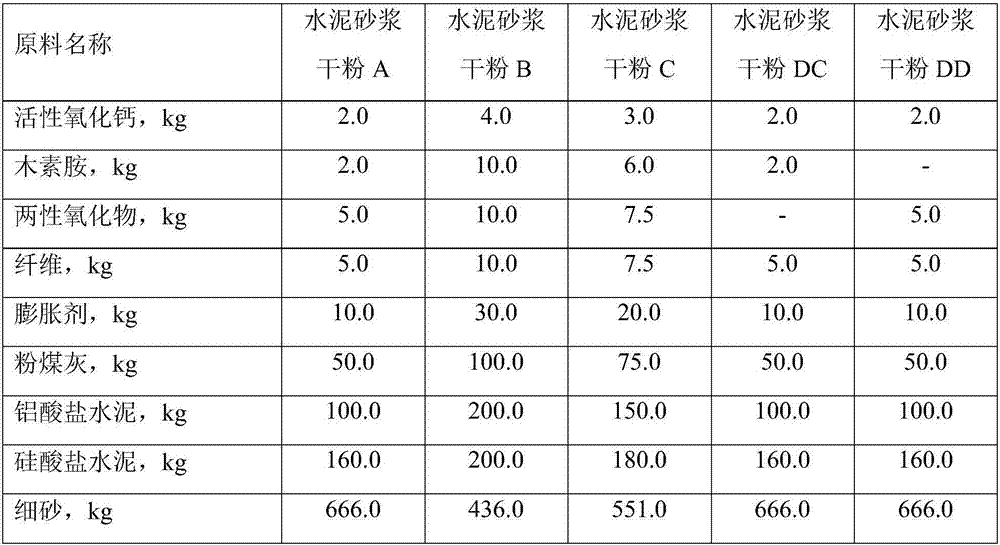

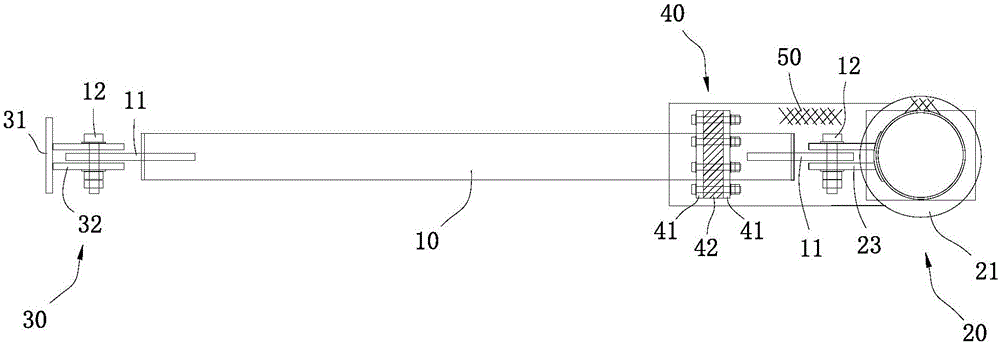

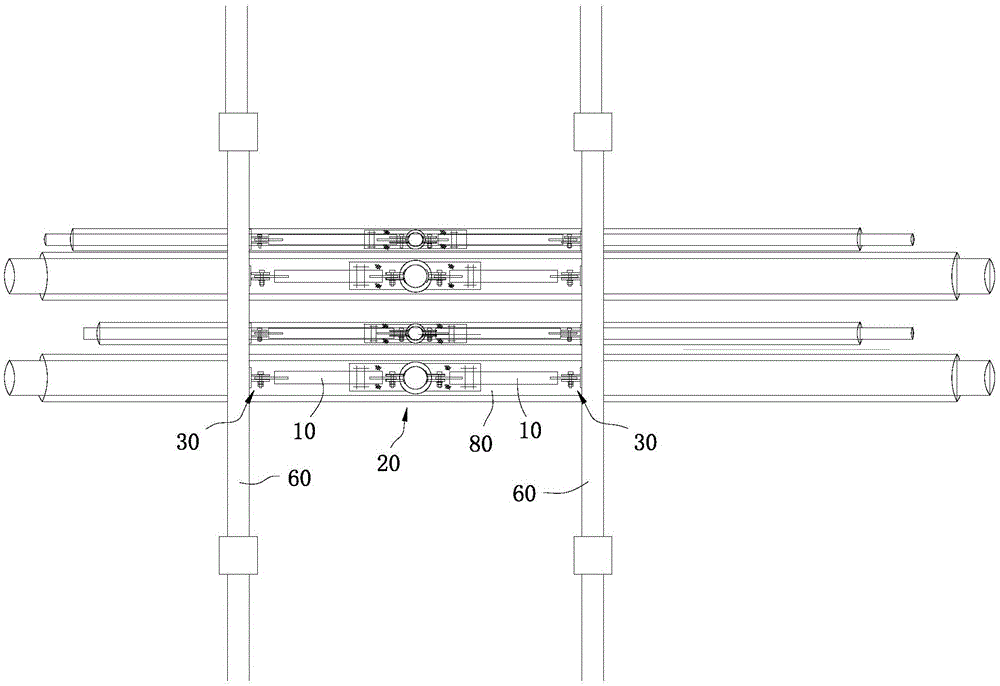

Fixing device for preventing sedimentation stretching of straight-buried pipe

ActiveCN105020472ASafe and stable useEffective "relief forcePipe laying and repairStructural engineeringPipe

The invention discloses a fixing device for preventing sedimentation stretching of a straight-buried pipe. The fixing device comprises a pull rod, a pipe fixing component and a structure fixing component, wherein the pipe fixing component comprises a fixed sleeve, an arc fixed plate and two pipe hinge plates; the structure fixing component comprises a fixed baseplate and two structure hinge plates; the two ends of the pull rod are respectively connected with hinge plates; the hinge plate at one end of the pull rod is hinged with the two pipe hinge plates; the hinge plate at the other end of the pull rod is hinged with the two structure hinge plates; the structure fixing component is fixed in strength points of such different buildings as a structural bearing platform and a ground beam; the pipe fixing component is fixed on the straight-buried pipe; as the two ends of the pull rod are hinged with the pipe fixing component and the structure fixing component, when the straight-buried pipe is stretched, the straight-buried pipe can be synchronously and uniformly stretched to the left and right sides from the middle, and the stretching stress of the straight-buried pipe is effectively dispersed; and when the straight-buried pipe is sedimentated, the pull rod can effectively unload to prevent the tensile failure.

Owner:GUANGDONG IND EQUIP INSTALLATION

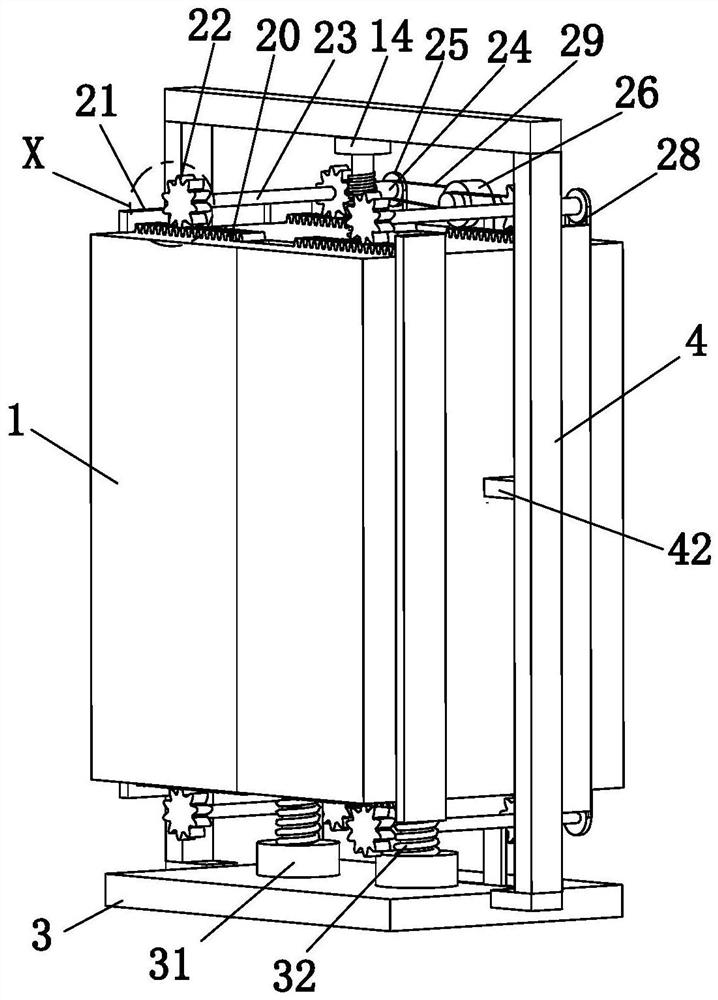

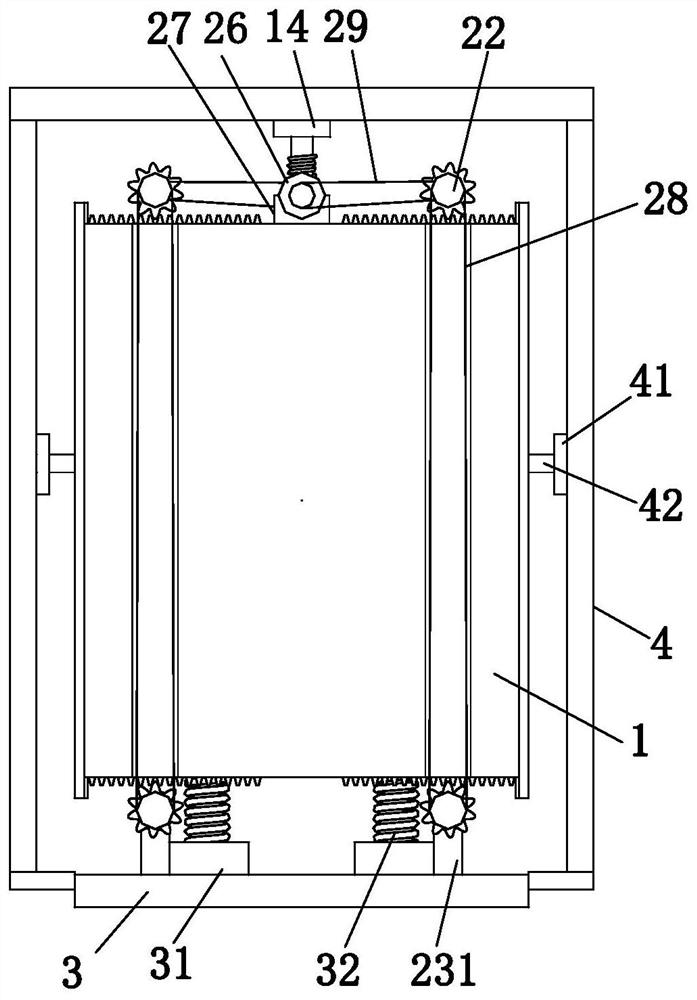

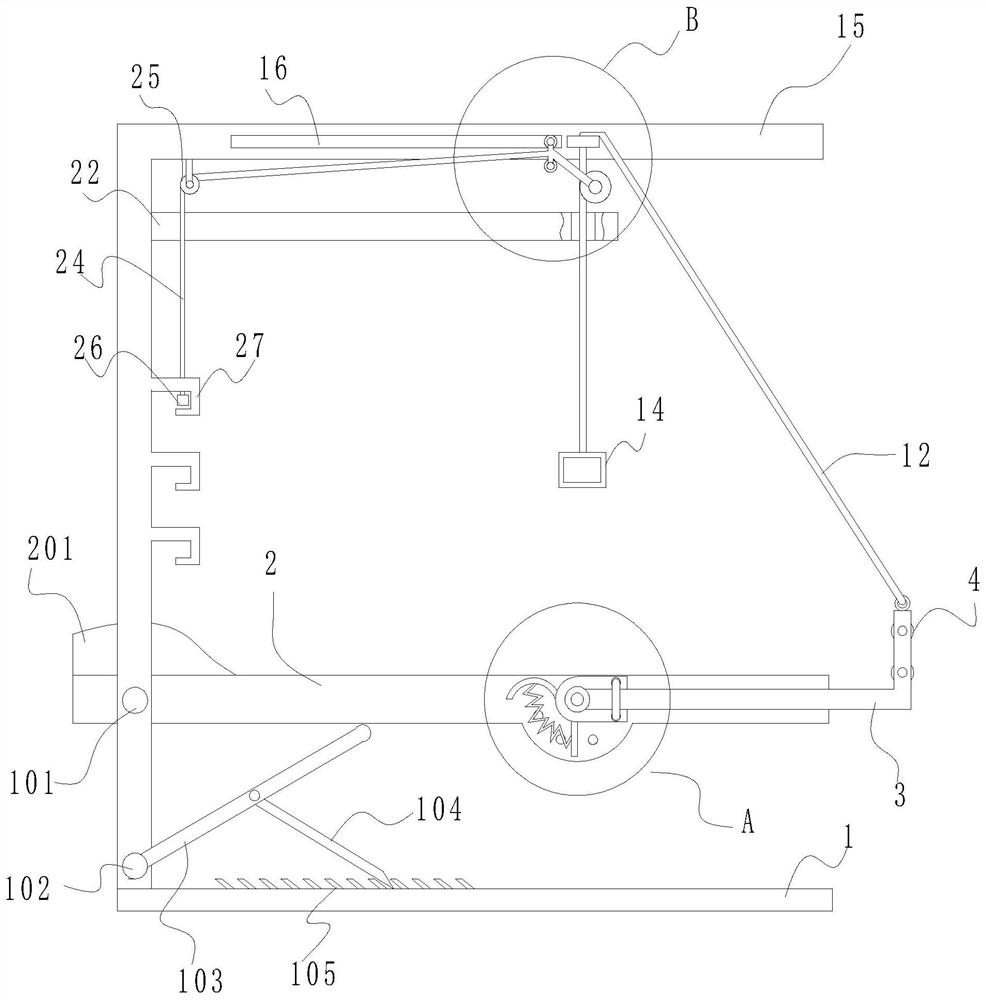

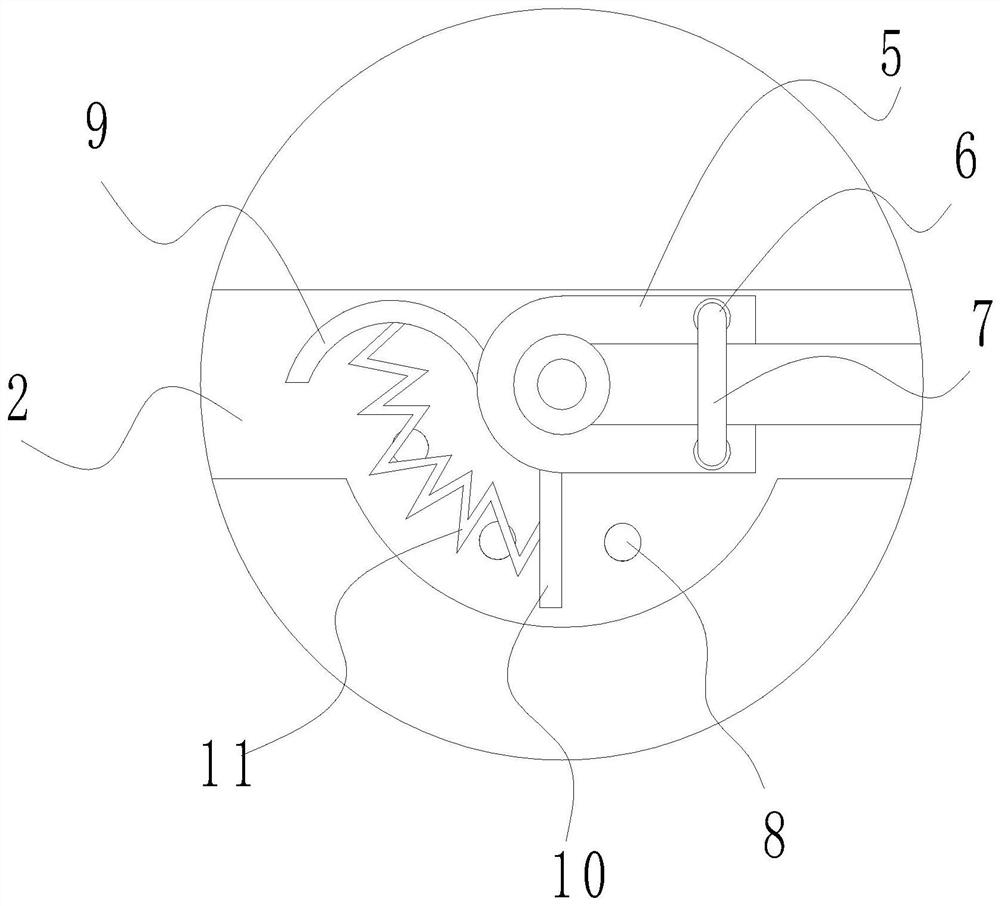

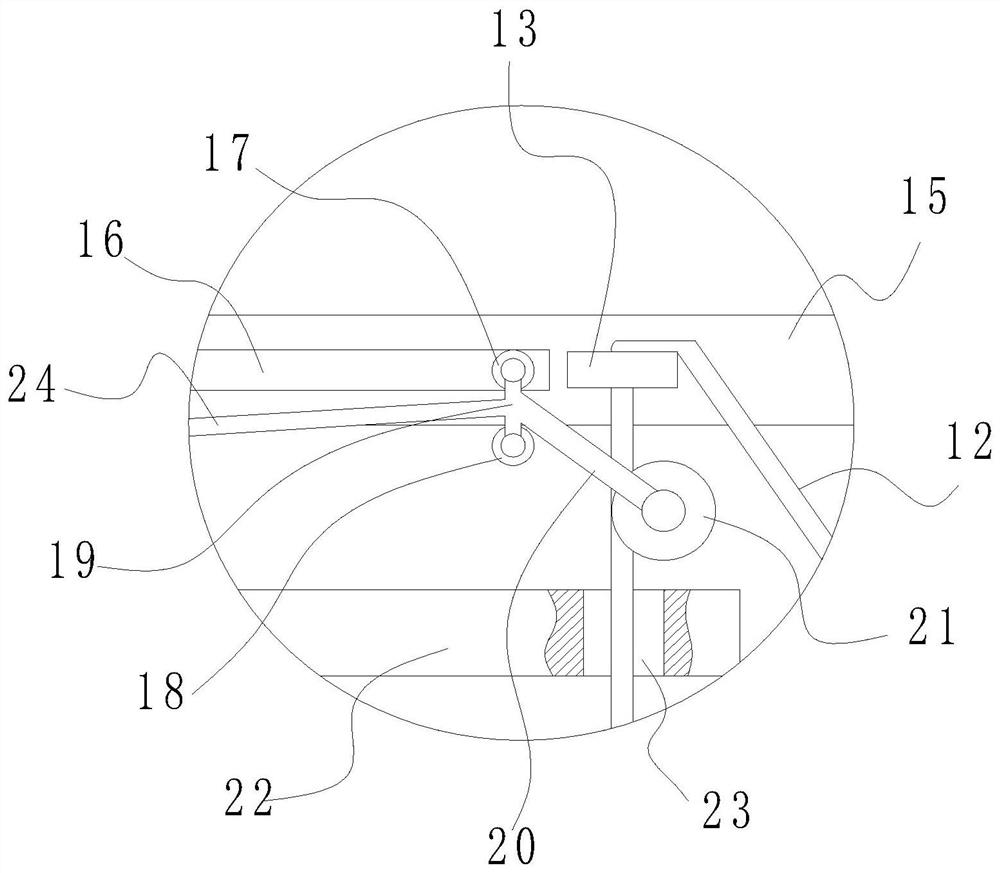

Anti-falling elevator car

ActiveCN111960212AReduce shockReduce the level of psychological panicElevatorsBuilding liftsControl theoryFriction force

The invention relates to an anti-falling elevator car which comprises a car body, an anti-falling device, a base and concentric-square-shaped racks. The anti-falling devices are symmetrically mountedat the upper and lower ends of the car body, the anti-falling devices are symmetrically arranged front and back, a base is arranged below the car body, the concentric-square-shaped racks are mounted at the left and right ends of the base, and the car body is located in the middle of the concentric-square-shaped racks. By changing design philosophy of size of a friction force between the car and awall for effective anti-falling arrangement, the anti-falling device can change the friction force between the elevator car and the wall in a quick falling process of the elevator car as a result of faults to improve the friction between the elevator car and the wall and decrease the falling speed of the elevator car to further achieve a good car anti-falling effect.

Owner:GUANGDONG SHENGDA ELEVATOR

Stretching device for bodybuilding

ActiveCN110215651AKnow the pressureAdjust in timeGymnastic exercisingChiropractic devicesLeg muscleEngineering

Owner:山东美能达健身器材股份有限公司

Temperature-control rigid expansion plugging working fluid for drilling fluid

PendingCN113122206AHigh elastic modulusHigh tensile strengthDrilling compositionFiberTemperature control

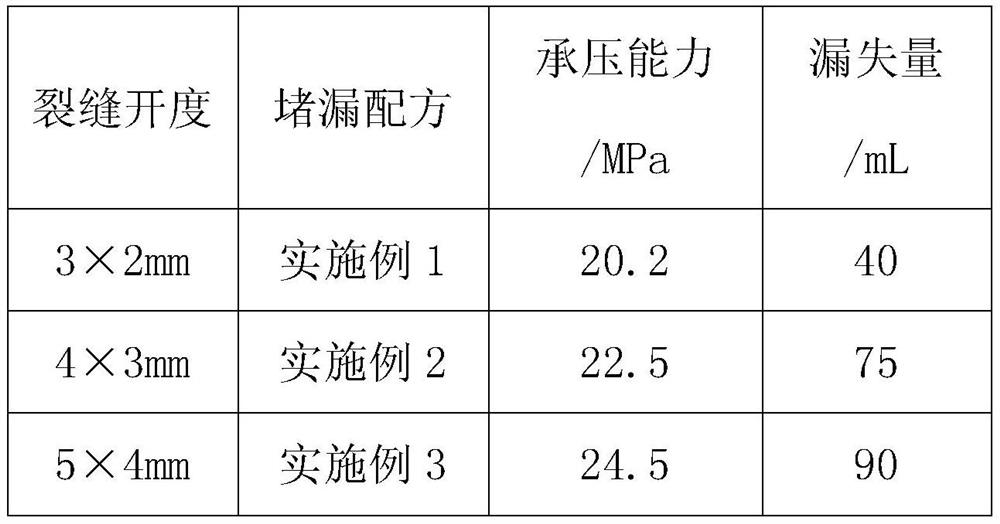

The invention relates to a temperature-control type rigid expansion plugging working fluid for a drilling fluid for a fractured leakage layer in the technical field of leakage prevention and plugging of the drilling fluid. The temperature-control type rigid expansion plugging working fluid comprises the following components in parts by weight: 100 parts of leaking stoppage base slurry, 5-10 parts of a temperature-control rigid expansion leaking stoppage agent, 10-20 parts of rigid particles, 4-10 parts of elastic particles, 2-5 parts of a flaky material and 0.2-0.4 part of a fiber material, and is compounded by optimizing the functions and particle sizes of the components. A temperature control type rigid expansion material serves as a core, deformation is generated through temperature induction excitation at a leakage channel to achieve bridging and blocking, rigid blocking materials and elastic blocking materials which are different in particle size and shape are cooperated, and a dense pressure-bearing blocking layer which is of a strong chain network structure and is high in self-adaptive capacity, high in temperature resistance, high in pressure-bearing capacity and low in leakage amount is formed, 3-5mm large opening of fractured leakage is sealed, the activation temperature can be adjusted from 70 DEG C to 100 DEG C, the pressure bearing capacity is larger than or equal to 20 MPa, and the leakage amount is smaller than or equal to 100 mL.

Owner:中石化石油工程技术服务有限公司 +2

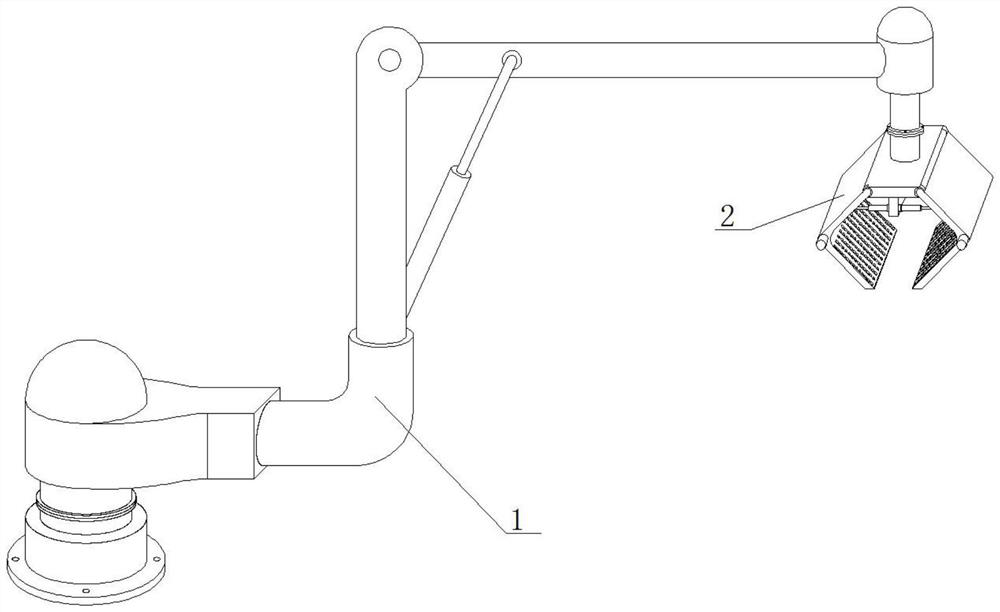

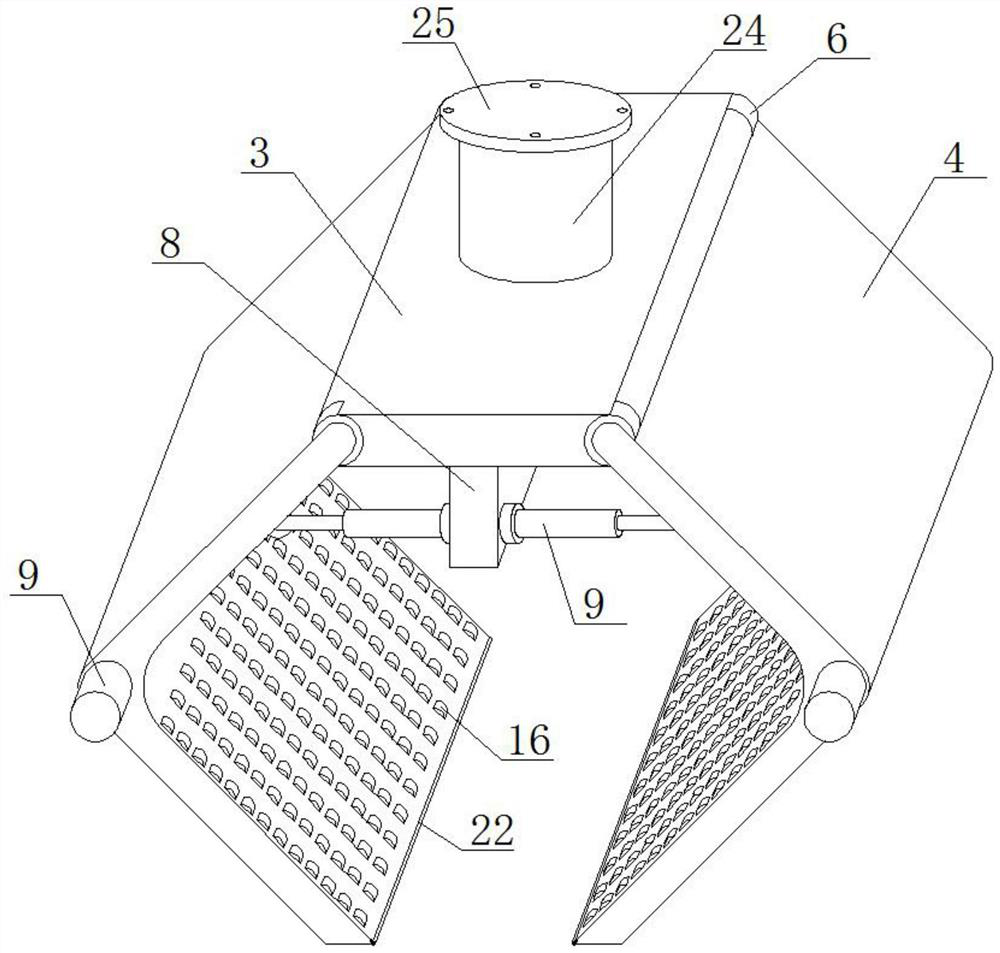

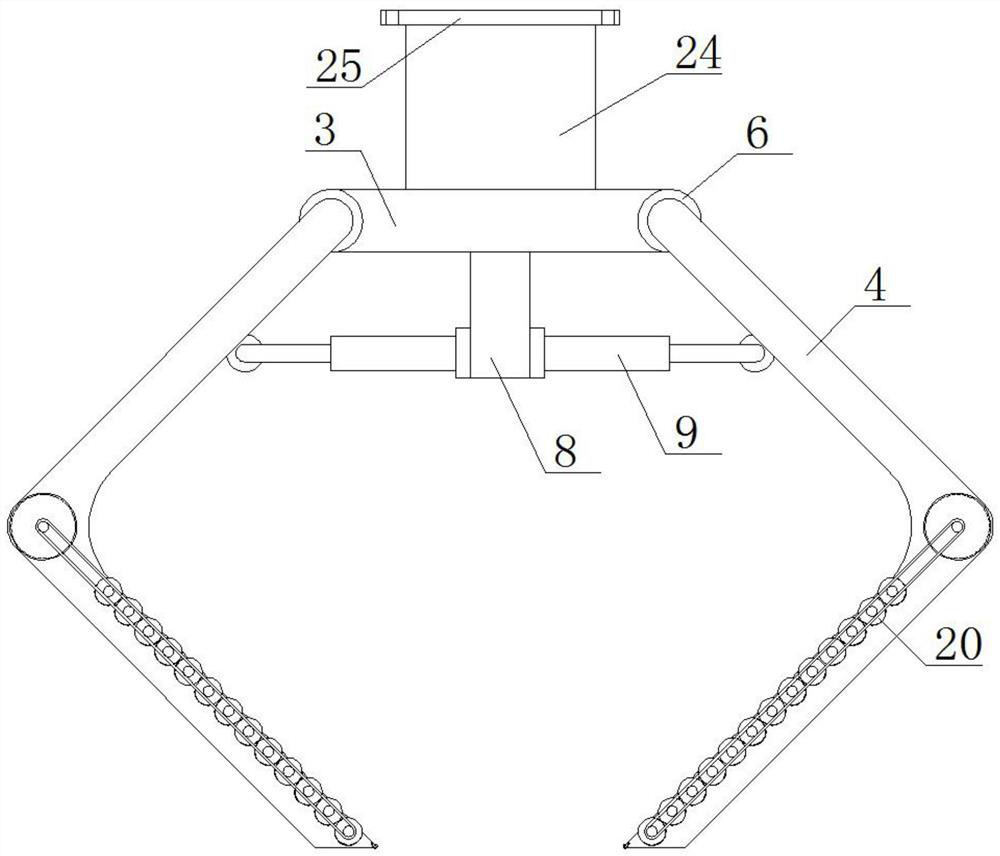

Stacking robot with sorting function

InactiveCN112777328AImprove tidinessEasy to pick upGripping headsStacking articlesStructural engineeringMechanical engineering

The invention provides a stacking robot with a sorting function. The stacking robot comprises a mechanical arm and an anti-damage clamp holder, wherein the anti-damage clamp holder comprises a middle mounting plate and two L-shaped clamping plates; a mounting vertical plate is fixedly mounted at the bottom of the middle mounting plate; and electric push rods are fixedly mounted on two sides of the mounting vertical plate. The stacking robot with the sorting function is reasonable in design; a plurality of guiding shifting devices are mounted on the L-shaped clamping plates of the anti-damage clamp holder; guiding shifting wheels of the guiding shifting devices are uniformly distributed on the surfaces of the L-shaped clamping plates; when bagged goods are stacked, in a process of clamping the bagged goods, the guiding shifting wheels rotate and can be lifted upwards from two sides of the bagged goods; and besides, bags of the bagged goods can be effectively prevented from being damaged, and the bagged goods are convenient to clamp.

Owner:王文豪

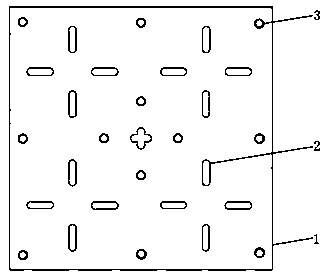

Production and installation process for steel flooring in factory

The invention discloses a production and installation process for steel flooring in a factory. The steel flooring comprises square steel floors, wherein non-slip strips are arranged on the surfaces ofthe square steel floors; reinforcing through holes are formed in the middles of the square steel floors; multiple non-slip strips are arranged; multiple reinforcing through holes are formed; the symmetrically arranged square steel floors are made of stainless steel. The production and installation process comprises the following steps: square cutting, laser drilling, hydraulic molding, glue-injection preparation, installation of steel flooring and the like. The invention relates to the technical field of factory flooring. According to the production and installation process for steel flooringin the factory, the product material and installation material have anti-rust characteristics and excellent non-slip effects and are neat and regular in non-slip lines, and excellent sense of wholeness is achieved after splicing installation. During installation, due to the operation of drilling and filling glue on the ground, the bar tying effect can be achieved, the through hole is filled withepoxy resin glue so as to form glue columns, the adhesive force is improved, vehicles with high strength and weight can be borne to pass, and the steel flooring is difficult to drop.

Owner:威海英纳吉精密机械有限公司

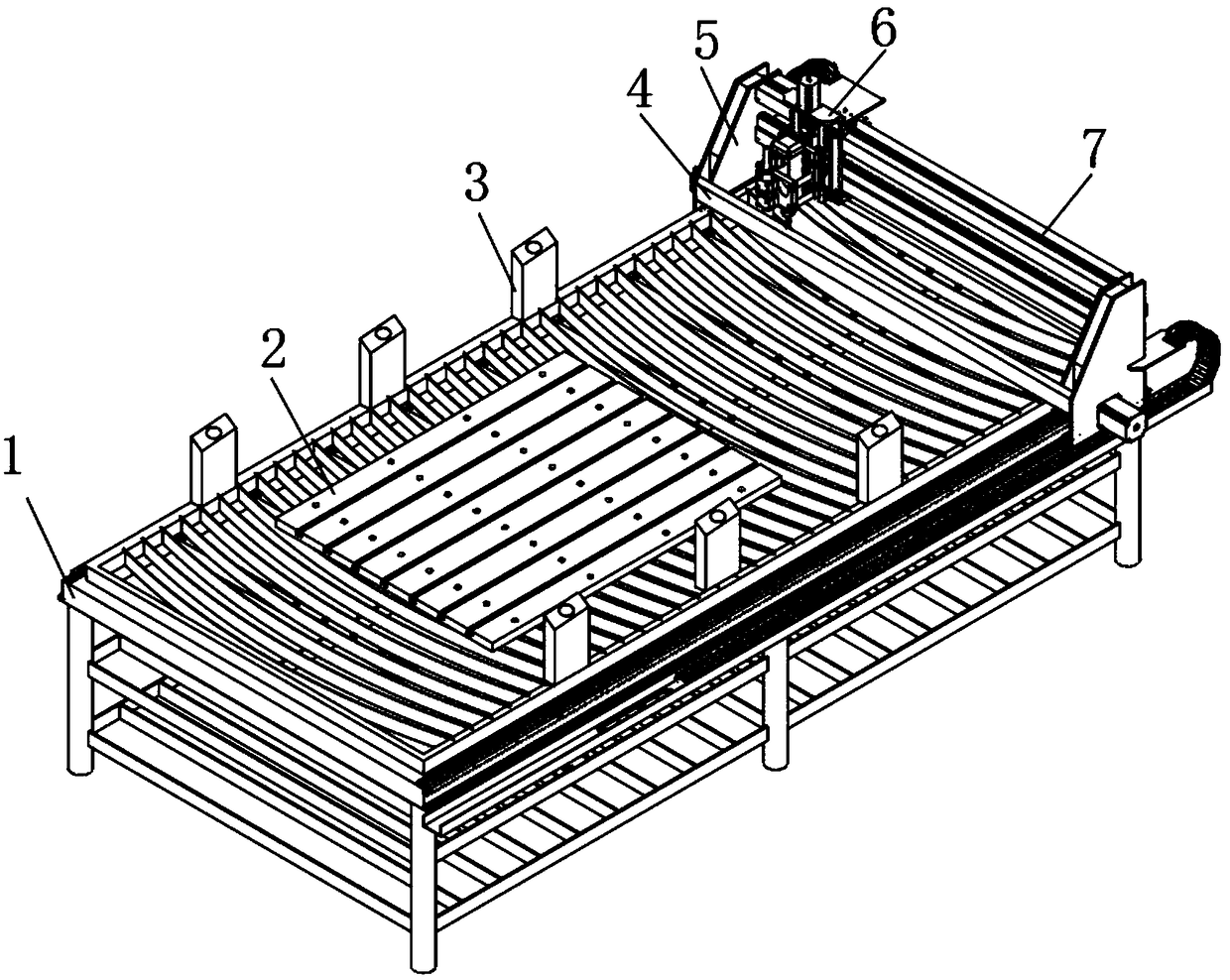

Conveying roller platform capable of being adjusted

Owner:无锡市升金源机械厂

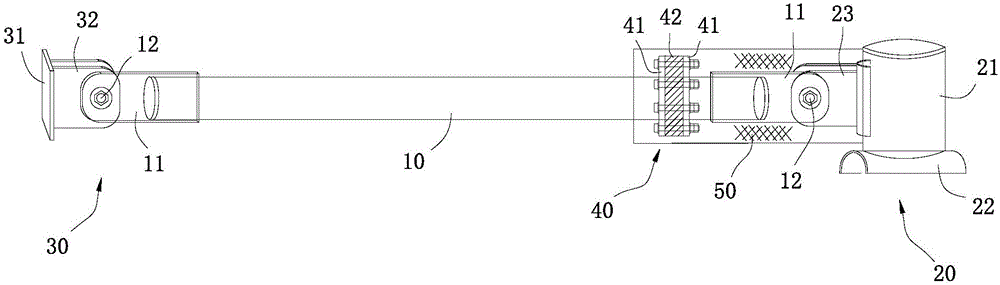

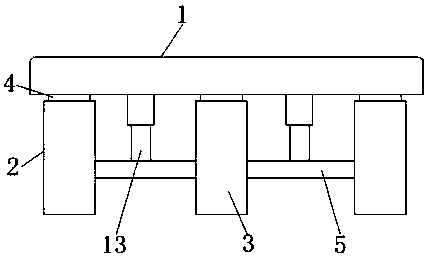

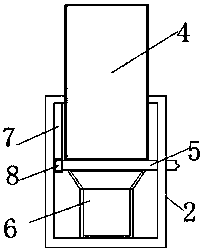

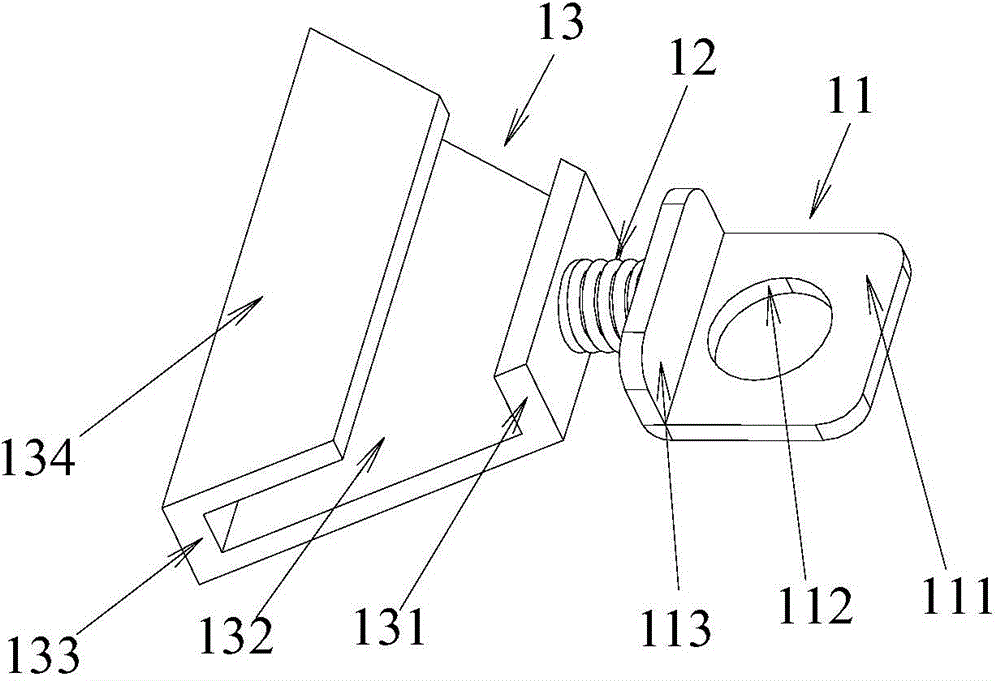

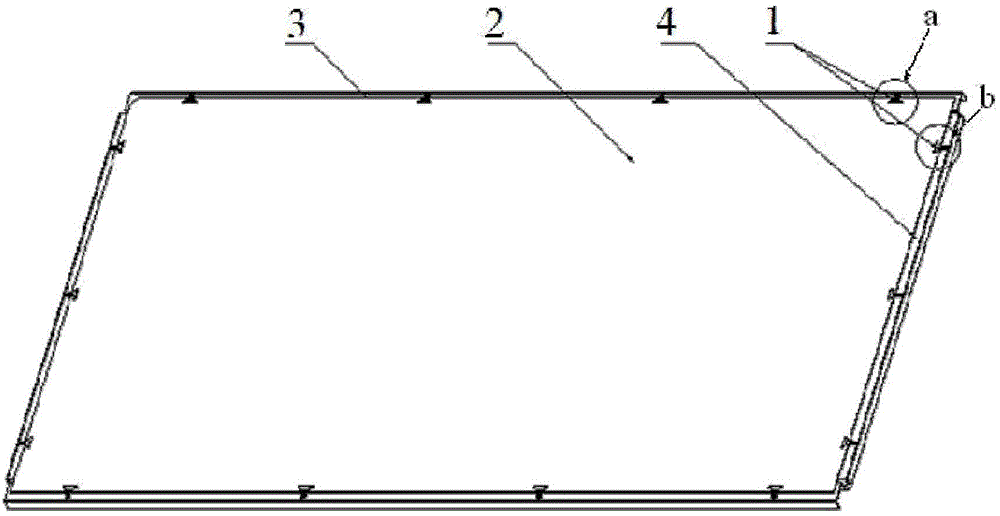

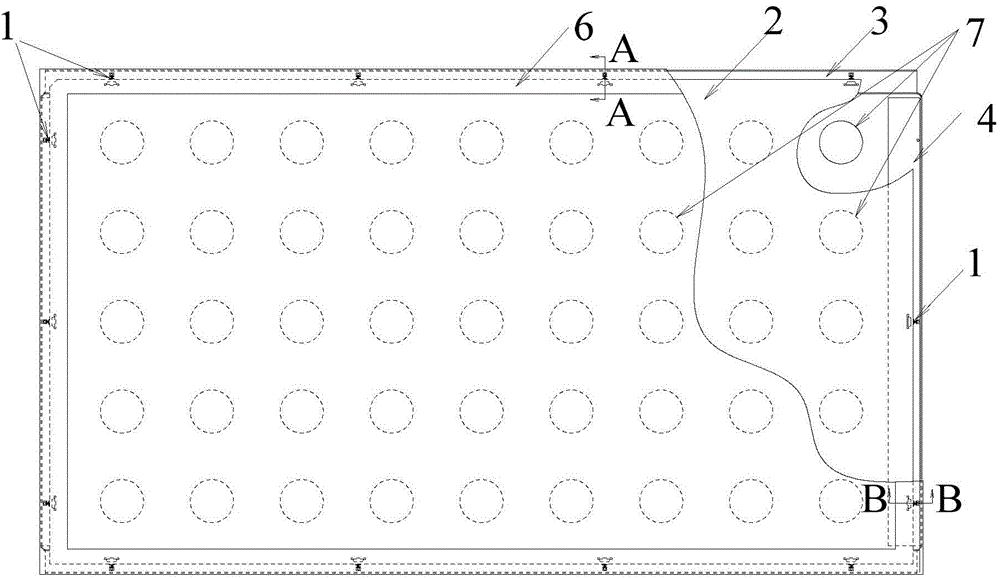

Fixing device, backlight source and display device

InactiveCN104570437APull up evenlyAvoid wrinklesPoint-like light sourceLight fasteningsWrinkle skinDisplay device

The invention discloses a fixing device, a backlight source and a display device. The fixing device comprises a hook, a connector and a fixed end, wherein the hook is connected with the fixed end by the connector. By adopting the fixing device, the backlight source and the display device, the flatness of a sheet-shaped material can be kept; moreover, a backlight source membrane material is symmetrically and uniformly stressed in each direction, a flat state is kept better and wrinkles are avoided being generated; the brightness of the display device is uniform, the phenomenon of nonuniform brightness cannot be generated, and the fixing device, the backlight source and the display device have excellent and stable quality.

Owner:BOE TECH GRP CO LTD

Multifunctional tendon pulling stool and using method thereof

InactiveCN104382720APlay a role in stretchingPromote recoveryGymnastic exercisingChiropractic devicesFatigue damageCervical spondylosis

The invention relates to a multifunctional tendon pulling stool and a using method thereof, and belongs to the field of health care instruments. The multifunctional tendon pulling stool is characterized by comprising a stool body, a vertical plate, a slope plate and a fixing belt, wherein a slot is formed in the end of the stool body; one or more vertical plates are inserted into the slot; the fixing belt is arranged on the vertical plate; the slope plate is arranged below the end, provided with the vertical plate in an inserted mode, of the stool body; one end of the slope plate is connected with the stool body; the other end of the slope plate is placed on the ground; and the height of the slope plate from the end connected with the stool body to the end placed on the ground is gradually reduced. By means of the multifunctional tendon pulling stool, a user can conveniently pull tendons, and the good rehabilitation effect on modern people suffering from accumulated fatigue damage such as cervical spondylosis and arthropathy can be achieved. In addition, the user can freely adjust the tendon pulling force and the figure angle in the tendon pulling process. The user can appropriately adjust the multifunctional tendon pulling stool according to needs; the safety performance is good; the universality is high; and the multifunctional tendon pulling stool is suitable for popularization in nowadays society.

Owner:张敬久

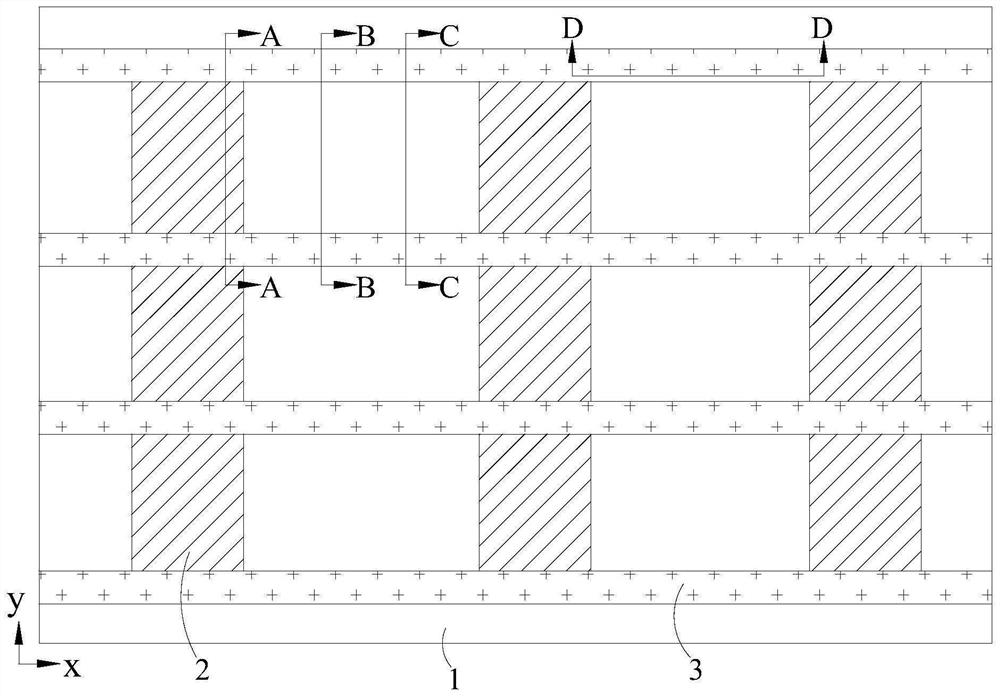

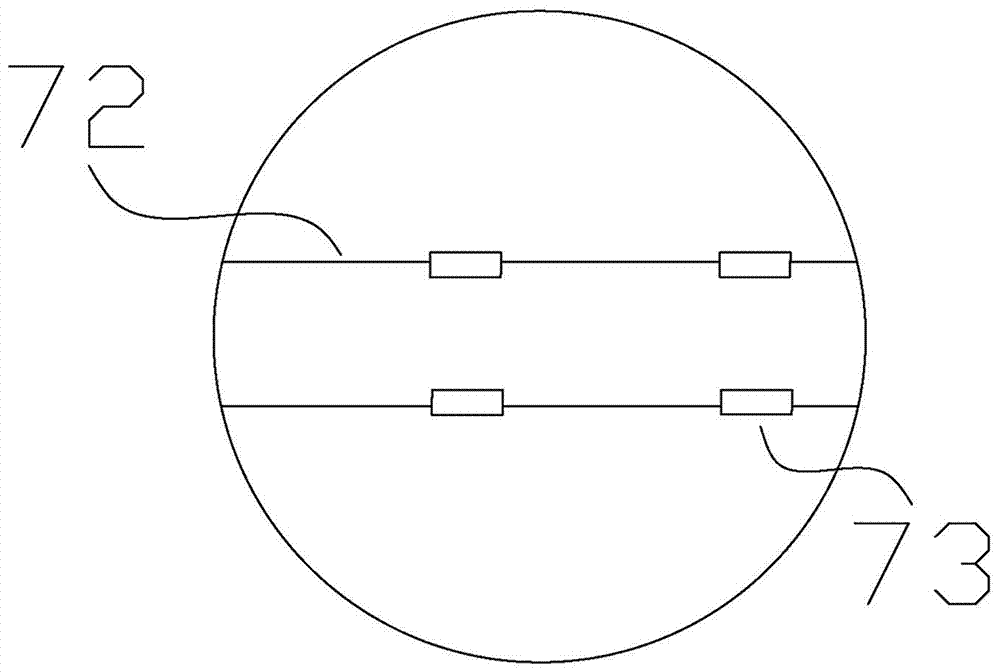

Display panel, preparation method thereof and display device

ActiveCN113193024AIncrease profitPlay a role in stretchingSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention relates to the technical field of display, and discloses a display panel, a preparation method thereof and a display device. The display panel comprises: a substrate having a first surface and a second surface opposite to each other; the first pixel limiting layer comprises a plurality of first pixel limiting strips, the first pixel limiting strips are arranged on the first face in the first direction, and a gap is formed between every two adjacent first pixel limiting strips; the second pixel limiting layer comprises a plurality of second pixel limiting strips, the second pixel limiting strips are arranged on the first face in the second direction and span the first pixel limiting layer, the first direction intersects with the second direction, each second pixel limiting strip is provided with a third face, a fourth face and a fifth face, the third face is the face close to the substrate, the fourth surface is a side surface which is far away from the substrate, the fifth surface is a side surface which is connected between the third surface and the fourth surface, the fifth surface extends along the second direction, and a plurality of protruding parts are arranged on the fifth surface. The display panel can improve the ink utilization rate of the light-emitting layer.

Owner:BOE TECH GRP CO LTD

Environment-friendly chopsticks and preparation method thereof

InactiveCN102048428AHigh hardnessSolve the problem of insufficient hardnessTablewaresPulp and paper industry

The invention belongs to the technical field of eating tools of chopsticks, in particular to disposable environment-friendly chopsticks, which comprise conical or cylindrical chopstick bodies formed by rolling sheets, and are characterized in that the section of the sheets before rolling is wavy or zigzag. The invention aims to provide disposable environment-friendly chopsticks with certain hardness, and aims to solve the problems that wooden or bamboo chopsticks cause environmental disruption and paper chopsticks have insufficient harness in the market at present.

Owner:于海宽

Lifting type plant extract distillate layering separation system

InactiveCN112169378AIncrease the support areaStable supportLiquid separationAgricultural engineeringSeparation system

The invention discloses a lifting type plant extract distillate layering separation system which comprises a first box body, a base and a plurality of water outlet pipes, the base is fixedly connectedto the lower surface of the first box body, and the water outlet pipes are fixedly connected to the interior of the left side of the first box body; an adjusting frame disc is fixedly mounted on thelower portion of the base, a mounting ring groove is formed in the outer ring of the adjusting frame disc, four lifting sleeves and an adjusting gear ring are rotatably mounted in the mounting ring groove, and when the height of a distillate storage box is adjusted, all the lifting sleeves are driven to rotate at the same time by rotating the adjusting gear ring, when the lifting sleeves rotate, lifting rods are pushed to ascend and descend, it is guaranteed that the lifting height of the lifting rods is uniform, lifting balance is guaranteed, limiting columns at the end of a connecting rod ispulled to move in a supporting sliding groove when the lifting rods ascends and descends, and the connecting rod can limit rotation of the lifting rod sand increase the supporting area of the liftingrods for the bottom of the first box body. And the supporting effect on the first box body is improved.

Owner:康季

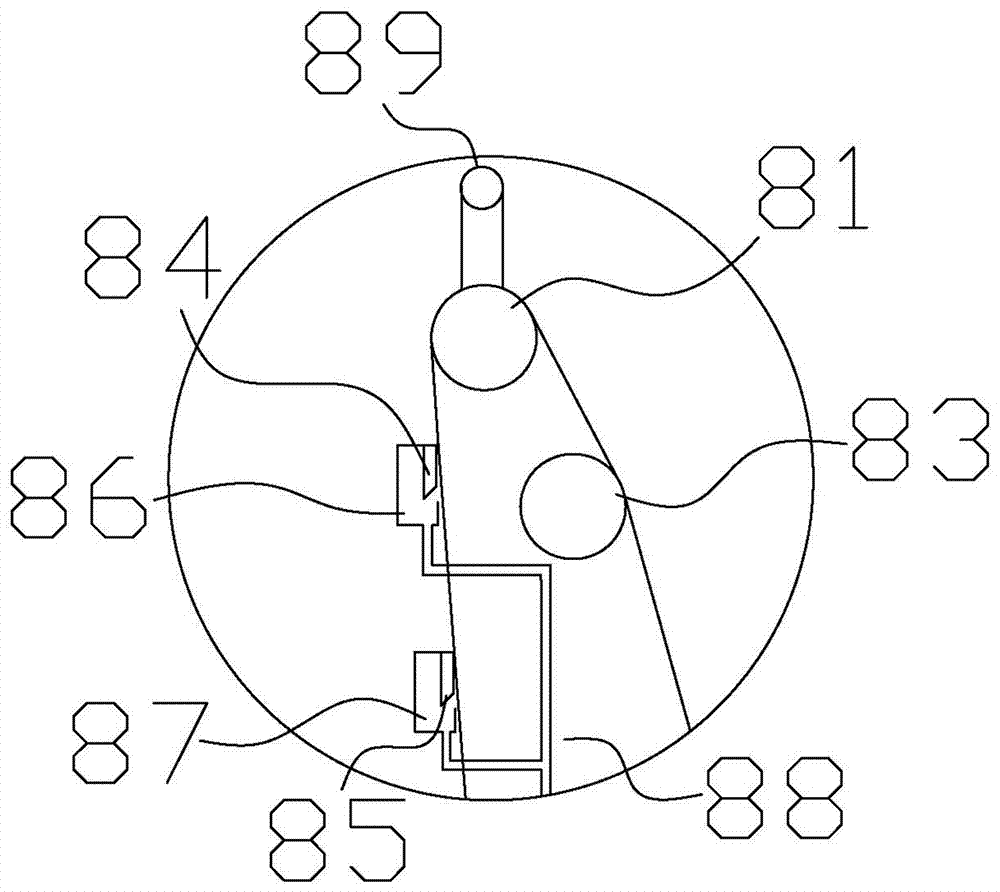

Circuit breaker arc-extinguishing chamber

PendingCN108010769AImprove impact resistanceEasy to assembleElectric switchesBlock matchCircuit breaker

The invention discloses a circuit breaker arc-extinguishing chamber which comprises a fixing plate and a plurality of arc chutes. The fixing plate comprises a bottom plate and two side plates symmetrically disposed at two opposite ends of the bottom plate. A plurality of exhaust passages are uniformly distributed on the bottom plate in the length direction of the bottom plate. A plurality of groups of fixing mechanisms are uniformly distributed on the side plates along the length direction of the side plates. The exhaust passages and the fixing mechanisms are successively staggered. The fixingmechanism includes a plurality of fixing holes uniformly distributed along the width direction of the side plate. The two opposite side ends of each arc chute are provided with fixed right angles recessed inward. Each fixed right angle is provided with a fixing block matching the fixing hole at a position corresponding to the fixing hole. One end of each fixing block penetrates through the corresponding fixing hole. The circuit breaker arc-extinguishing chamber is reasonable in structural design, good in impact resistance effect, good in heat dissipation effect, can improve arc extinguishingefficiency, and can improve the working stability of the circuit breaker when used.

Owner:GACIA ELECTRICAL APPLIANCE

Multifunctional nursing massage bed

ActiveCN109481222AImprove efficiencySave manpower and material resourcesChiropractic devicesPediatricsBed boards

The invention discloses a multifunctional nursing massage bed. The multifunctional nursing massage bed comprises a bed body, a bed plate and a massage head, wherein the bed plate is mounted in the bedbody; the middles of the two ends of the bed plate are rotatably connected with two ends of the bed body through rotating shafts; a plurality of loading holes are uniformly formed in the bed plate inthe thickness direction; the inside of each loading hole is longitudinally connected with an elastic column; the top of each elastic column is connected with a massage head; a plurality of massage layers are connected between two side plates on two sides of one end; the outer side of each massage layer is connected with an inflating layer; the outer side of each inflating layer is connected witha vibrating layer; the outer side of each vibrating layer is connected with a protecting layer; and the massage layers are connected with each other through hook-and-lope tapes on the two sides. The massage bed is diversified in function, can meet demands of different patients, is simple to operate during use, and is convenient and fast to adjust. The patient can be massaged in all directions, themassaging efficiency is high, and the effect is good.

Owner:JIANGSU VOCATIONAL COLLEGE OF MEDICINE

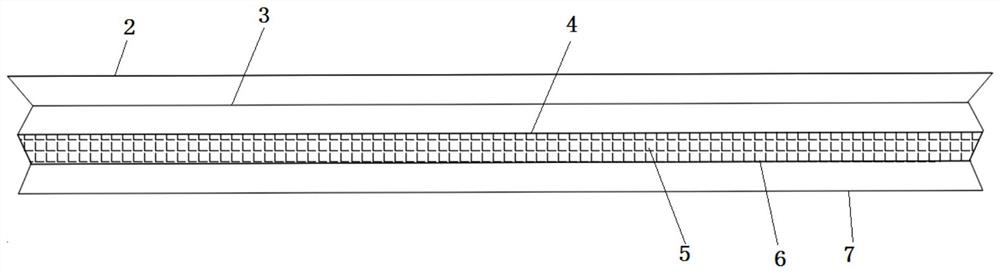

High-barrier composite woven packaging bag

InactiveCN113086390AImprove oxygen barrierImprove moisture resistanceBagsSacksMoisture resistanceMechanical engineering

The invention discloses a high-barrier composite woven packaging bag. The high-barrier composite woven packaging bag comprises a packaging bag body, wherein the packaging bag body comprises a woven outer barrier layer, a first PE waterproof layer is arranged in the outer barrier layer, an anti-cutting layer is arranged in the first PE waterproof layer, the anti-cutting layer is connected with a connecting adhesive film, the connecting adhesive film is connected with a second PE waterproof layer, and a lining layer is arranged in the second PE waterproof layer; a handle and an inlet are arranged at the top of the packaging bag body, an inlet cover is arranged at the inlet, first adhesive cloth is arranged along the edge of the inlet cover, and second adhesive cloth is arranged on the packaging bag body corresponding to the edge of the inlet cover; and a mobile phone bag is arranged on the circular-arc-shaped inlet cover, so that the performance of oxygen resistance, moisture resistance, light resistance and the like of the woven packaging bag is effectively improved, and the using effect is better. Due to the design of a reinforcing layer, the structure of the bag body is firmer and more reliable, the overall impact resistance is good, the toughness is good, and the connecting adhesive film plays a role in stretching, so that the bag body has certain stretching shrinkage resistance; and a mobile phone is prevented from falling off and is convenient to use.

Owner:青铜峡市强力塑料包装制品有限公司

stretching device for fitness

ActiveCN110215651BPlay a role in stretchingGood massageGymnastic exercisingChiropractic devicesLeg muscleStructural engineering

Owner:山东美能达健身器材股份有限公司

A multifunctional nursing massage bed

ActiveCN109481222BImprove massage efficiencySave manpower and material resourcesChiropractic devicesPhysical medicine and rehabilitationNursing care

The invention discloses a multi-functional nursing massage bed, which comprises a bed body, a bed board and a massage head. A bed board is installed inside the bed body. The inside of the bed board is evenly provided with several loading holes along the thickness direction, and the inside of the loading holes is connected with an elastic column longitudinally, and the top of the elastic column is connected with a massage head, and between the two side plates on both sides of one end There are several massage layers connected, the outside of the massage layer is connected with an inflatable layer, the outside of the inflatable layer is connected with a vibrating layer, the outside of the vibrating layer is connected with a protective layer, and the several massage layers are connected by two sides Velcro to connect each other. The massage table has various functions, can adapt to the needs of different patients, and is easy to operate and convenient to adjust during use. It can perform a full range of massage on the patient, with high massage efficiency and good effect.

Owner:苏州酷锐斯医疗科技有限公司

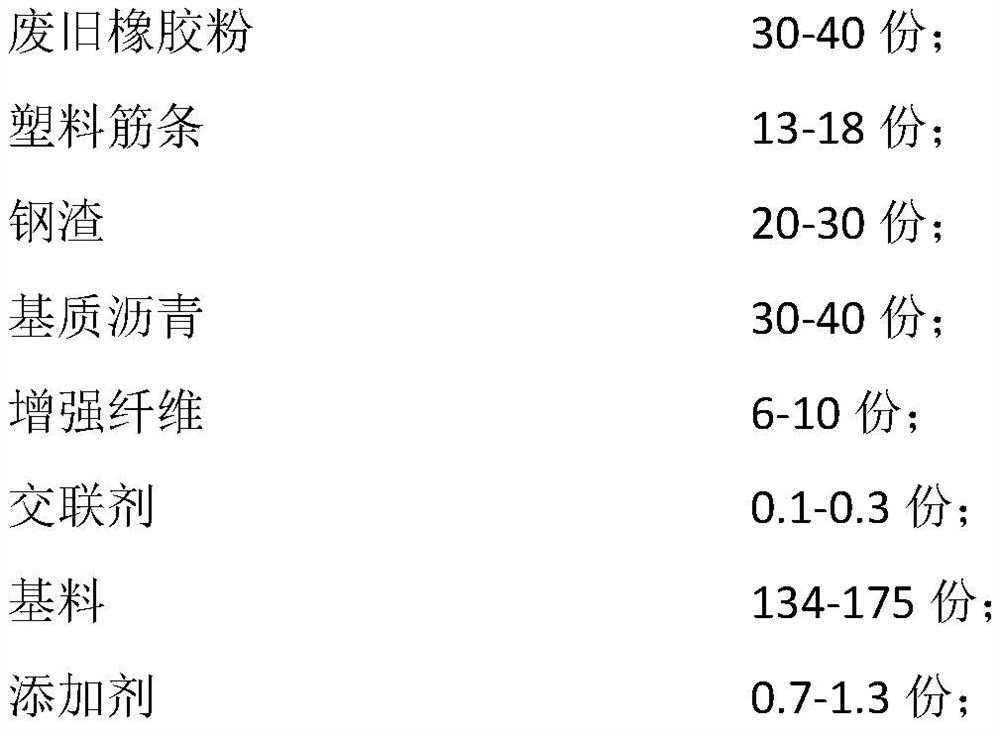

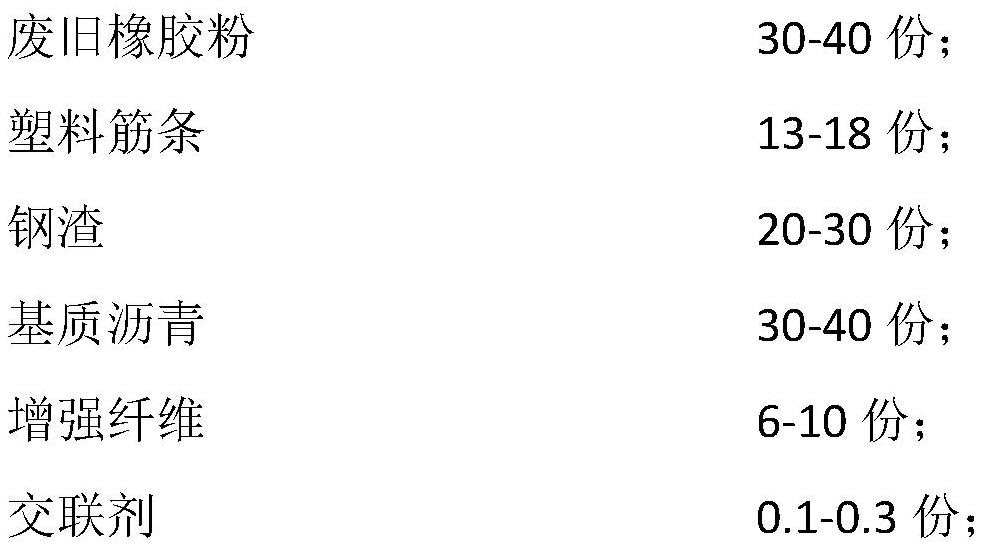

High-strength environment-friendly water-permeable material, preparation method thereof, and pavement prepared from the material

ActiveCN111704415BHigh strengthHigh porosityIn situ pavingsSolid waste managementFiberArchitectural engineering

The invention proposes a high-strength environment-friendly water-permeable material, a preparation method thereof, and a pavement prepared by the material, which belong to the technical field of pavement paving material preparation. The pavement structure includes the following components and their weight ratios: waste rubber powder: 30-40 parts; plastic ribs: 13‑18 parts; matrix asphalt: 30‑40 parts; reinforcing fiber: 6‑10 parts; crosslinking agent: 0.1‑0.3 parts; base material: 140‑185 parts; ; Water: 20‑30 parts. The high-strength environment-friendly permeable pavement of the invention can improve the strength of the pavement and prolong the service life of the pavement.

Owner:CHANGAN UNIV

Automobile intercooler protective plate

InactiveCN106930822APlay a role in stretchingAvoid breakingInternal combustion piston enginesArchitectural engineeringThermal expansion

The invention relates to the field of automobile accessories, in particular to an automobile intercooler protective plate. Through the automobile intercooler protective plate, the problem that the root of a radiator is fractured due to the fact that the thermal expansion speed of a radiating pipe is different from that of the protective plate can be effectively solved. The automobile intercooler protective plate structurally comprises a main protective plate body including a first branch plate, a second branch plate and a third branch plate; a single-row bracket is arranged between the first branch plate and the second branch plate and sleeved with a first spring; a double-row bracket is arranged between the second branch plate and the third branch plate and sleeved with a second spring; and the bottom of the main protective plate body is provided with an elastic isolation pad, and a vertical through hole and a transverse through hole are formed in the elastic isolation pad and communicate with each other. The automobile intercooler protective plate is simple in structure, convenient to use and suitable for automobiles of multiple models.

Owner:十堰市鹏展工贸有限公司

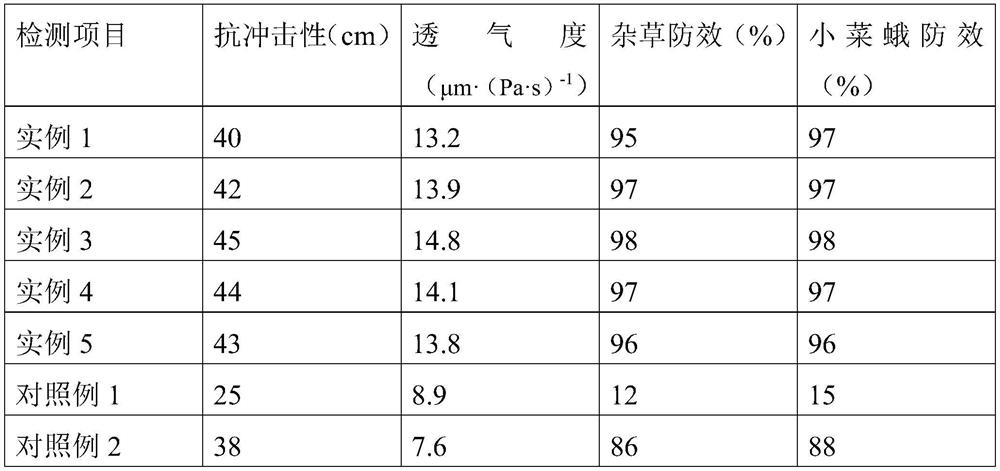

Agricultural mulching film with deinsectization and weeding functions and preparation method thereof

InactiveCN113234278AImprove impact resistanceConnectivityPlant protective coveringsPolymer scienceFiber composition

The invention relates to an agricultural mulching film with disinsection and weeding functions and a preparation method thereof, and belongs to the technical field of agricultural products. The preparation method comprises the following steps: by taking hickory nut green pericarp as a raw material, utilizing allelopathic substances and fiber components in the hickory nut green pericarp, carrying out a series of modification treatment, matching with silicon dioxide aerogel to prepare a mixed filler, doping the obtained mixed filler into a film matrix, and finally carrying out extrusion granulation, pressing and film blowing to finally prepare the agricultural mulching film with the deinsectization and weeding functions. The agricultural mulching film prepared by the invention is excellent in disinsection and weeding functions, excellent in air permeability and impact resistance and wide in application prospect.

Owner:JIANGSU WUJIN HIGHWAY PLANT NURSERY

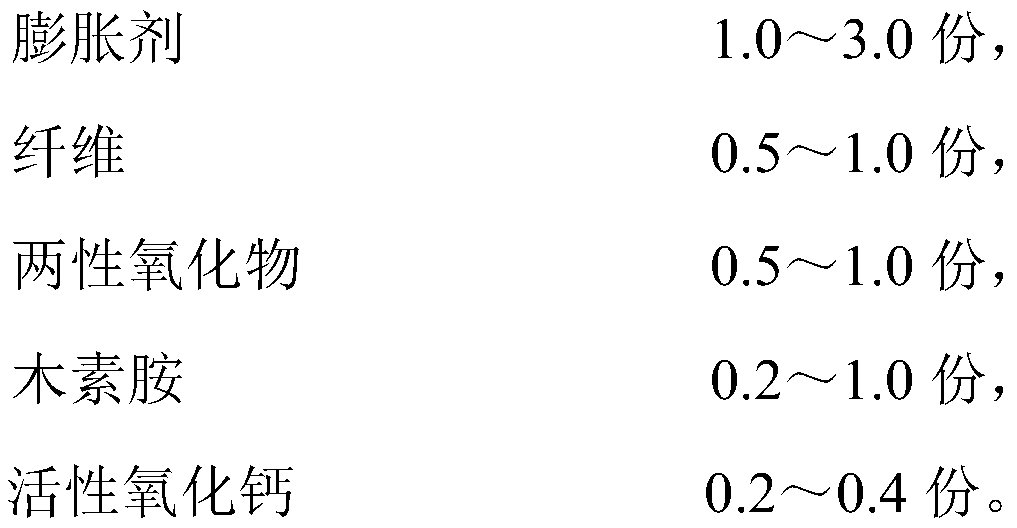

A kind of cement mortar additive and its preparation method and use method

The invention discloses a cement mortar additive and a preparation method and use method thereof. The cement mortar additive comprises a swelling agent, fibers, amphoteric oxide, lignin amine and active calcium oxide. In use, the prepared cement mortar additive, sand, cement and water are stirred to be uniform, and then cement mortar is obtained. The cement mortar prepared by using the additive has the advantages of being high in early strength, resistant to crack, free of efflorescence and the like, the preparation cost is low, and the cement mortar prepared by using the additive can meet the requirements of the governance of urban street manholes and the rapid pavement repair of airfield runways and concrete pavements or culverts and further can meet the rapid construction requirements of secondary grouting of equipment foundations, foundation bolt reinforcement and the like.

Owner:辽宁兆利高新路面材料有限公司

A kind of multifunctional fitness equipment

ActiveCN110237497BEasy to holdPlay a role in stretchingMuscle exercising devicesHuman bodyMuscle training

The invention discloses a multifunctional body-building apparatus, which comprises a base, on which a lying bed is installed, and two sides of the lying bed are respectively pivotally connected with rotating poles, and a top plate is arranged above the lying bed, and the two sides of the top plate are Two guide sleeves are respectively arranged near the middle part, one end of the stay rope is connected to the end of the rotating pole, and the other end of the stay rope passes through the guide sleeve and is connected with a handle for easy grasping. Fix the rotating rods, the human body is lying on the bed, you can perform sit-up training, you can also hold the handles tightly with both hands, use the arm strength to pull the upper body of the human body, you can exercise the arm strength; fix one of the rotating rods At a certain position, the other rotating rod is not fixed, and the two feet are respectively fixed on the two rotating rods, and the handle connected to the unfixed rotating rod is pulled, so as to exercise the strength of the arms and pull the legs at the same time. Muscle training; multi-function, can realize the exercise of multiple parts.

Owner:ANHUI BUSINESS COLLEGE

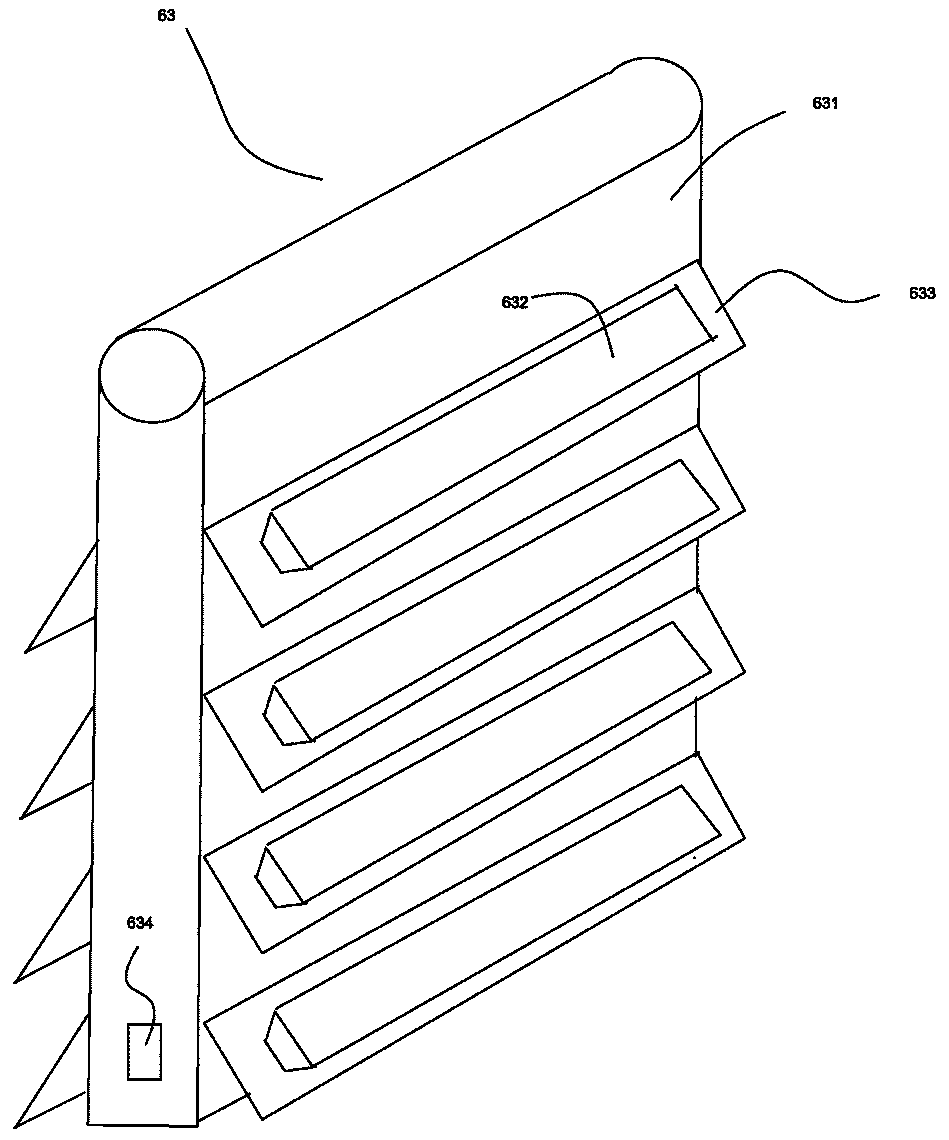

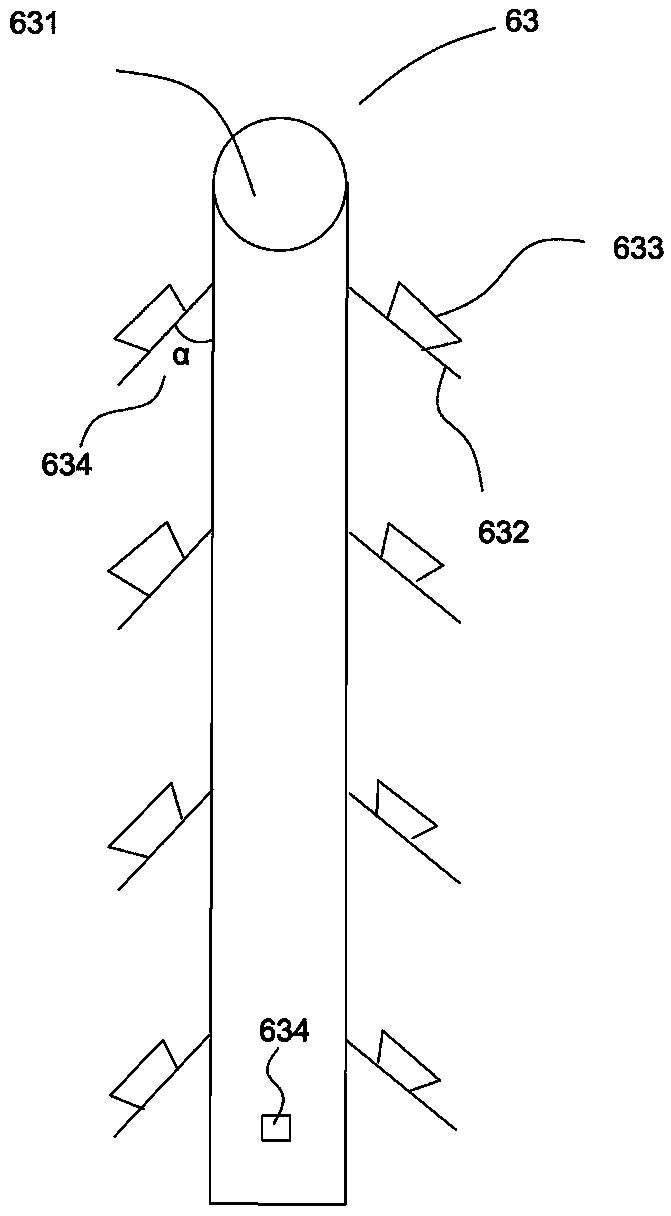

Efficient rubber cooling machine

The invention discloses an efficient rubber cooling machine. The efficient rubber cooling machine comprises a feeding conveyer belt, a lifting conveyer belt connected with the feeding conveyer belt, and a recirculation cooler arranged below the lifting conveyer belt. The feeding conveyer belt is provided with a speed controller. The recirculation cooler comprises supports which are oppositely arranged and are further provided with air cooling structures and a plurality of suspension structures which are arranged between the supports and can make circulated movement. Each suspension structure comprises a moving plate and a plurality of supporting plates which are arranged at the two sides of the moving plate and used for supporting rubber. An included angle alpha is formed between the supporting plates and the corresponding moving plates. The included angle alpha can be adjusted. The efficient rubber cooling machine is good in cooling effect and high in efficiency, the structure is simple and operation is convenient.

Owner:ANHUI LIXIN RUBBER TECH CO LTD

An integrated device for sizing and shaping cloth

InactiveCN105714499BReduce manufacturing costUniform conjunctivaSucessive textile treatmentsLiquid/gas/vapor removalSlurryPulp and paper industry

Owner:HUZHOU CHANGSHENG BELT IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com