Cement mortar dry powder as well as preparation method and application thereof

A cement mortar and dry powder technology, which is applied in the field of cement mortar dry powder and its preparation, can solve the problems of calcium oxide active ingredient content requirements, freeze-thaw resistance defects, metal component corrosion, etc., and achieve controllable initial hardening time and good crack resistance and freeze-thaw resistance, the effect of promoting the formation of crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

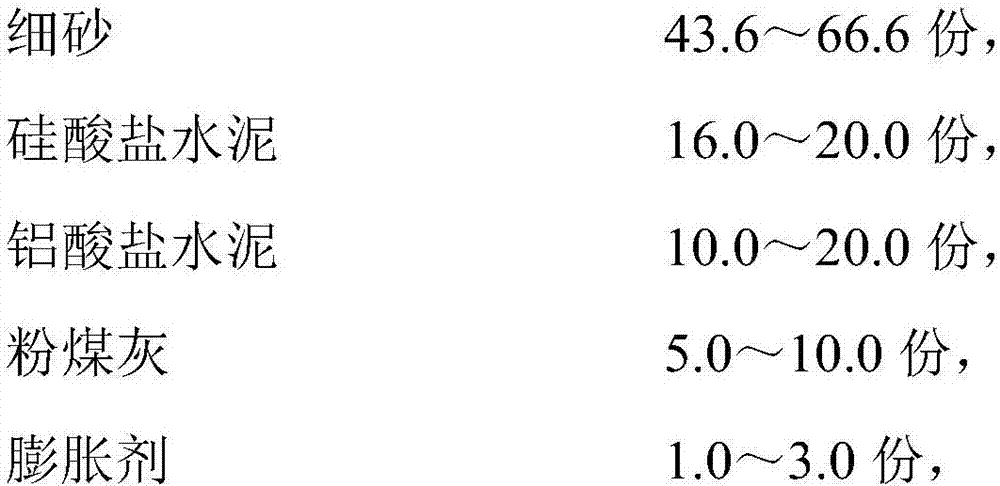

Method used

Image

Examples

Embodiment 1

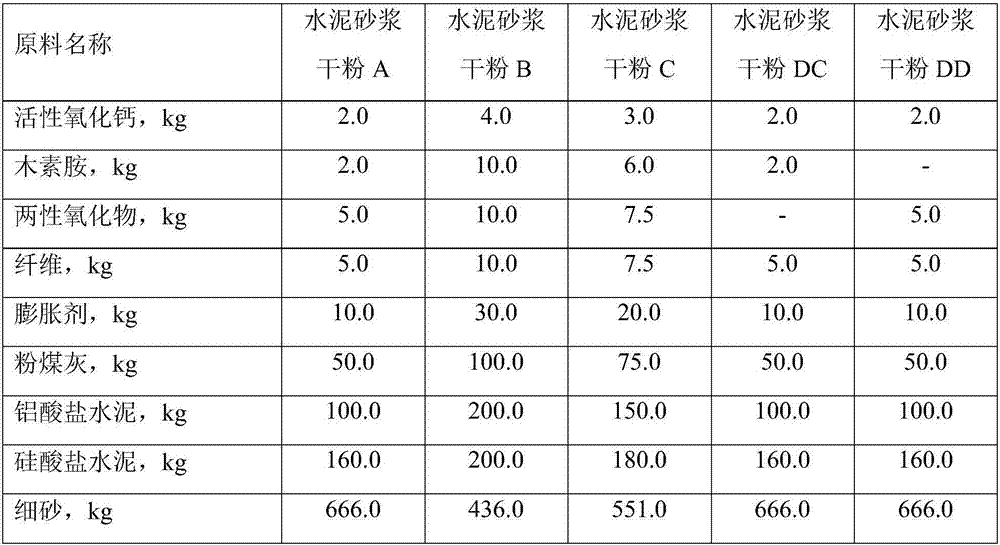

[0049] Under confirming that various raw materials and equipment dry state, take by weighing the active calcium oxide of 2.0kg (active calcium oxide mass content is 80%), the lignin amine (quaternary ammonium salt type) of 2.0kg, the amphoteric oxide of 5.0kg ( Al 2 o 3 ), 5.0kg of fiber (kapok fiber), add to 100.0kg of quartz sand and mix well; then add 10.0kg of U-shaped expansion agent (specific surface area is 2800cm 2 / g), 50.0kg of fly ash (particle size 0.05mm), 100.0kg of aluminate cement with a strength grade of 425, and 160.0kg of Portland cement with a strength grade of 525, mix well; finally add 566.0 kg of quartz sand, fully mixed, to obtain cement mortar dry powder A of the present invention, sealed packaging. See Table 1 for the ratio.

Embodiment 2

[0051] After confirming the dry state of various raw materials and equipment, weigh 4.0kg of activated calcium oxide (the mass content of activated calcium oxide is 72%), 10.0kg of ligninamine (tertiary amine type), 10.0kg of amphoteric oxide (ZnO ), 10.0kg of fiber (polyester fiber), add to 36.0kg of river sand and mix well; then add 30.0kg of U-shaped expansion agent (specific surface area is 3000cm 2 / g), 100.0kg of fly ash (particle size 0.04mm), 200.0kg of aluminate cement with strength grade of 325, 200.0kg of Portland cement with strength grade of 425, mix well; finally add 400kg The river sand is fully mixed uniformly to obtain dry cement mortar powder B of the present invention, which is sealed and packaged. See Table 1 for the ratio.

Embodiment 3

[0053] After confirming the dry state of various raw materials and equipment, weigh 3.0kg of active calcium oxide (active calcium oxide mass content is 75%), 6.0kg of ligninamine (polyamine type), 7.5kg of amphoteric oxide (TiO 2 ), 7.5kg of fiber (asbestos fiber), add to 51.0kg of sea sand and mix well; then add 20.0kg of U-shaped expansion agent (specific surface area is 2900cm 2 / g), 75.0kg of fly ash (particle size is 0.06mm), 150.0kg of aluminate cement with a strength grade of 525, and 180.0kg of Portland cement with a strength grade of 325, mix well; finally add 500kg The sea sand is fully mixed uniformly to obtain dry cement mortar powder C of the present invention, which is sealed and packaged. See Table 1 for the ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com