Agricultural mulching film with deinsectization and weeding functions and preparation method thereof

An agricultural mulch film and functional technology, applied in the field of agricultural mulch film and its preparation, can solve the problems of affecting the scope of use, increasing labor costs, poor impact resistance, etc., and achieve the effects of strong toughness, improved waterproof performance, and improved impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

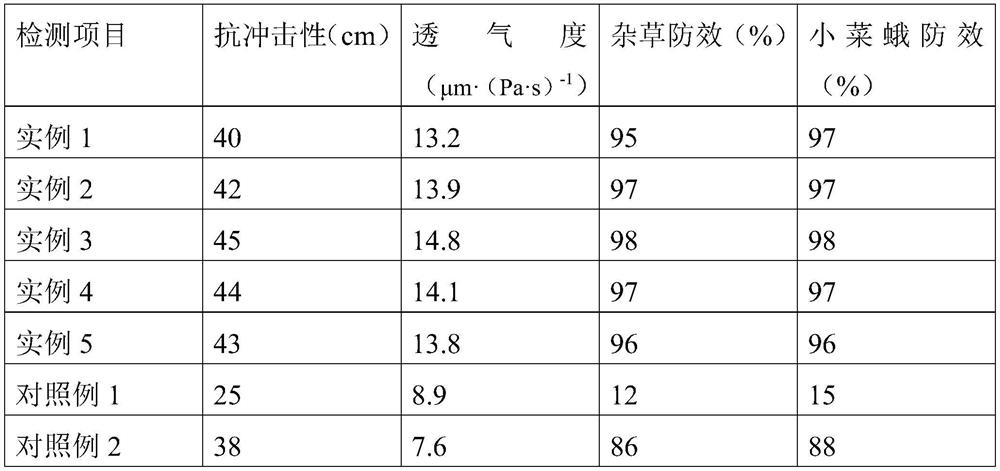

Examples

example 1

[0044] (1) Weigh the hickory green fruit peel and lay it flat on the ground, repeatedly roll it 20 times with a stone roller, collect the rolling product, and obtain the rolling product, and mix the rolling product with a mass fraction of 5% sodium hydroxide solution Mix according to the mass ratio of 1:10, pour into the reaction kettle, heat up to 80°C, stir and react for 30min to obtain the pretreated product;

[0045] (2) Mix the above pretreated product with citric acid solution with a mass fraction of 10% in a mass ratio of 1:8 and put it into a high-temperature and high-pressure cooking tank. Set the temperature in the high-temperature and high-pressure cooking tank to 250°C and the pressure to 1.7MPa , under the above conditions, high temperature and high pressure cooking for 10h, to obtain the reaction product;

[0046] (3) above-mentioned reaction product is packed in the reaction kettle, then add the cellulase of reaction product quality 2% in the reaction kettle, an...

example 2

[0052] (1) Weigh the hickory green fruit peel and lay it flat on the ground, repeatedly roll it 20 times with a stone roller, collect the rolling product, and obtain the rolling product, and mix the rolling product with a mass fraction of 5% sodium hydroxide solution Mix according to the mass ratio of 1:10, pour into the reaction kettle, heat up to 80°C, stir and react for 30min to obtain the pretreated product;

[0053] (2) Mix the above pretreated product with citric acid solution with a mass fraction of 10% in a mass ratio of 1:8 and put it into a high-temperature and high-pressure cooking tank. Set the temperature in the high-temperature and high-pressure cooking tank to 250°C and the pressure to 1.7MPa , under the above conditions, high temperature and high pressure cooking for 10h, to obtain the reaction product;

[0054](3) above-mentioned reaction product is packed in the reaction kettle, then add the cellulase of reaction product quality 2% in the reaction kettle, and...

example 3

[0060] (1) Weigh the hickory green fruit peel and lay it flat on the ground, repeatedly roll it 20 times with a stone roller, collect the rolling product, and obtain the rolling product, and mix the rolling product with a mass fraction of 5% sodium hydroxide solution Mix according to the mass ratio of 1:10, pour into the reaction kettle, heat up to 80°C, stir and react for 30min to obtain the pretreated product;

[0061] (2) Mix the above pretreated product with citric acid solution with a mass fraction of 10% in a mass ratio of 1:8 and put it into a high-temperature and high-pressure cooking tank. Set the temperature in the high-temperature and high-pressure cooking tank to 250°C and the pressure to 1.7MPa , under the above conditions, high temperature and high pressure cooking for 10h, to obtain the reaction product;

[0062] (3) above-mentioned reaction product is packed in the reaction kettle, then add the cellulase of reaction product quality 2% in the reaction kettle, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com