High-strength environment-friendly water-permeable material, preparation method thereof, and pavement prepared from the material

A permeable material and environmentally friendly technology, which is applied in clay preparation devices, chemical instruments and methods, and coagulation pavement for on-site paving, etc., can solve the problem of low overall strength of pavement materials, reduce urban heat island effect, and extend service life. , the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the above-mentioned high-strength environment-friendly water-permeable material comprises the following steps:

[0050] A) Melt the base asphalt and raise the temperature to 170-190°C, mix waste rubber powder and plastic ribs into the base asphalt, and shear and mix for 40-50 minutes at a shear speed of 2000-5000 rpm, Add surfactant and keep stirring for 5-10 minutes, grind with shear colloid mill for 10-20 minutes, add cross-linking agent, keep stirring for 2-3 hours to form rubber composite modified asphalt;

[0051] B) mixing steel slag, reinforcing fiber, coarse aggregate, fine aggregate, cement and water for 30 to 60 seconds to prepare a mixed base material;

[0052] C) Add the rubber composite modified asphalt prepared in step A) to the mixed base material prepared in step B), and stir for 3-5 minutes under the condition of 175-185°C to obtain a high-strength environment-friendly permeable material.

[0053] Preferably, step B) is specif...

Embodiment 1

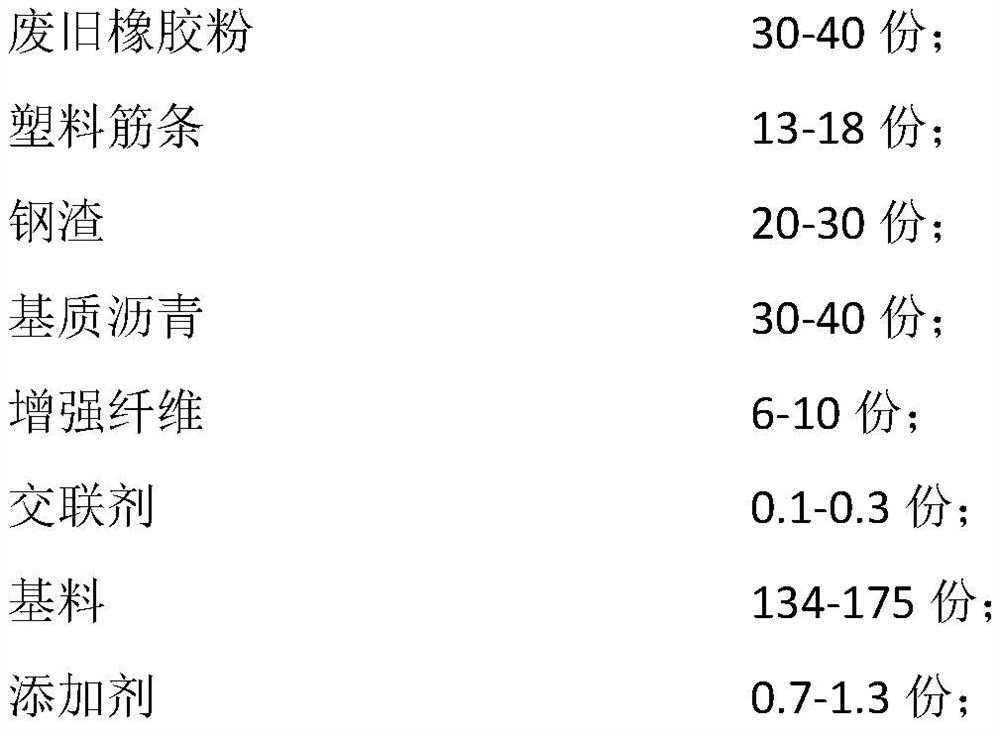

[0055] The high-strength environment-friendly water-permeable material of this embodiment is formed by the following components and their weight ratios:

[0056]

[0057]Waste rubber powder is crushed and sieved from waste tires. The mesh size of the sieve is 20 mesh. Rod-shaped structure, steel slag is formed by crushing industrial scrap steel, its particle size is 2mm, the surfactant is a non-ionic surfactant, of which the non-ionic surfactant is alkyl alcohol amide polyoxyethylene ether, cross-linked The agent is sulfur powder, the reinforcing fiber is glass fiber, the coarse aggregate and fine aggregate are both basalt, the cement is 42.5 grade Portland cement, and the matrix asphalt is No. 70 A grade petroleum asphalt.

[0058] The preparation method of the high-strength environment-friendly water-permeable material of this embodiment comprises the following steps:

[0059] A) Melt the base asphalt at 130°C and heat it up to 170°C, mix waste rubber powder and plastic ...

Embodiment 2

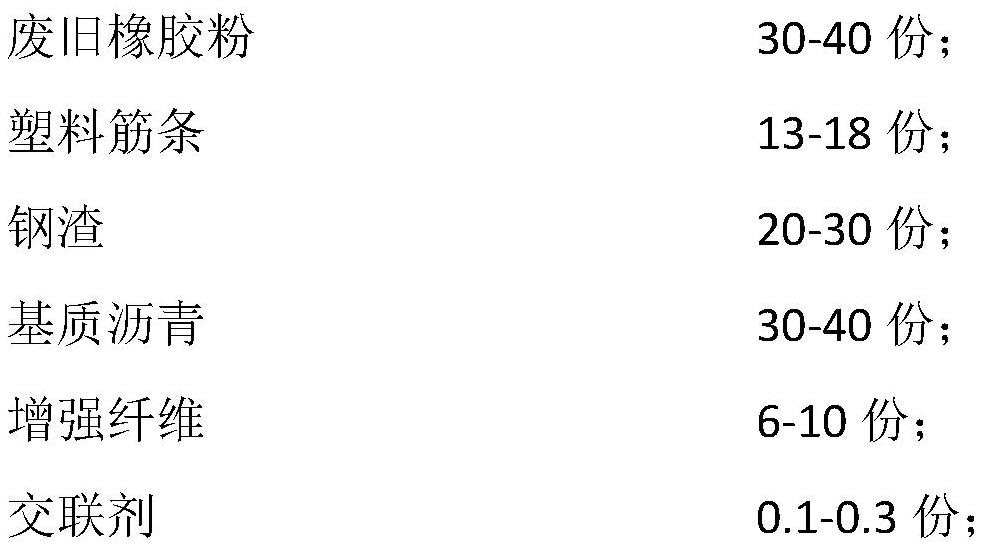

[0063] The high-strength environment-friendly water-permeable material of this embodiment is formed by the following components and their weight ratios:

[0064]

[0065]

[0066] Waste rubber powder is crushed and sieved from waste tires. The mesh size of the sieve is 20 mesh. Rod-shaped structure, steel slag is formed by crushing industrial scrap steel, its particle size is 2mm, the water reducer is naphthalene-based water reducer, and the surfactant is non-ionic surfactant, of which the non-ionic surfactant is alkane Alcohol amide polyoxyethylene ether, crosslinking agent is sulfur powder, reinforcing fiber is glass fiber, coarse aggregate and fine aggregate are both basalt, cement is 42.5 grade Portland cement, base asphalt is No. 70 A grade petroleum asphalt .

[0067] The preparation method of the high-strength environment-friendly water-permeable material of this embodiment comprises the following steps:

[0068] A) Melt the base asphalt at 130°C and heat it up ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com