Lifting type plant extract distillate layering separation system

A plant extraction and separation system technology, which is applied in the field of lift-type plant extraction and distillate stratified separation systems, can solve the problem that the bottom cannot be guaranteed to lift synchronously.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

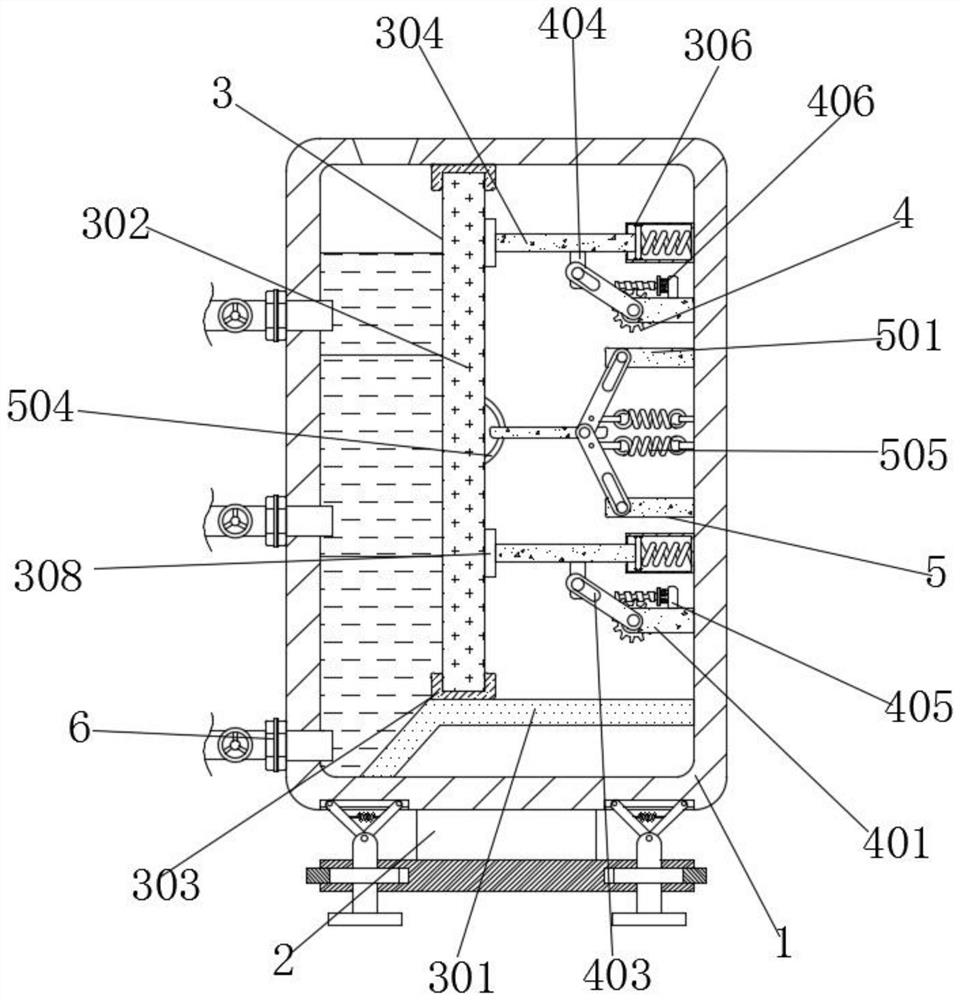

[0035] see Figure 1-2 , the invention provides a technical solution: a lift-type plant extract distillate layered separation system, including a first box 1, a base 2 and an outlet pipe 6, the lower surface of the first box 1 is fixed with a base 2, and the second A plurality of water outlet pipes 6 are fixedly connected to the left side of the box body 1;

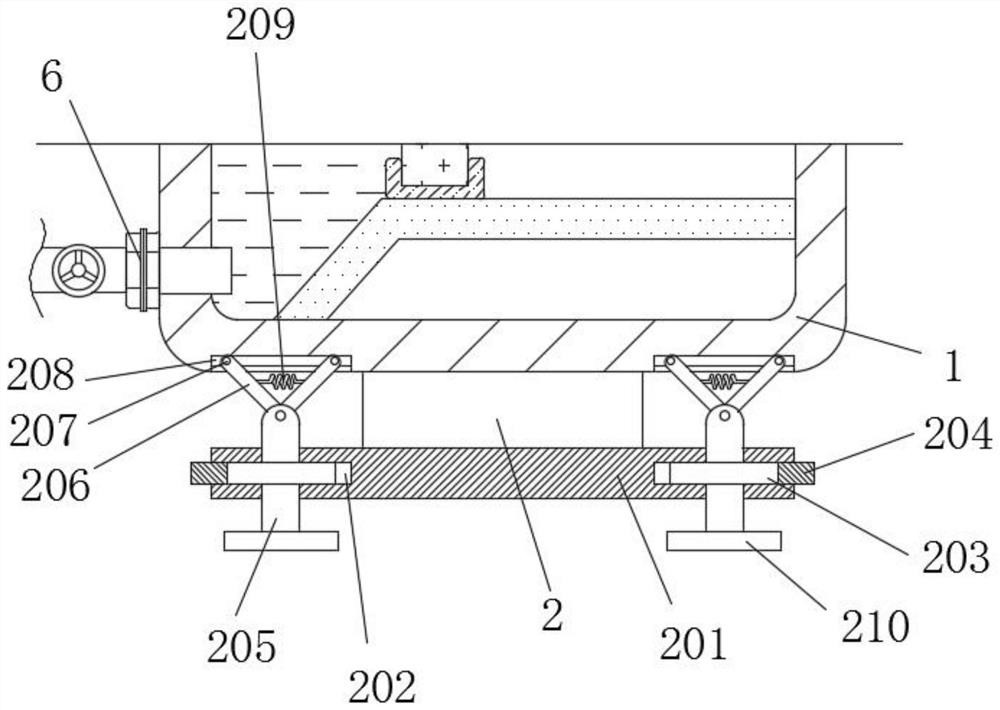

[0036]The lower part of the base 2 is fixedly equipped with an adjusting frame plate 201, and the outer ring of the adjusting frame plate 201 is provided with an installation ring groove 202, and the inside of the installation ring groove 202 is rotatably equipped with four lifting sleeves 203 and an adjusting gear ring 204, and the outer surface of the lifting sleeve 203 is provided with There are teeth, and the lifting sleeve 203 is engaged on the inner side of the adjusting gear ring 204. Each lifting sleeve 203 is respectively sleeved on the independent lifting rod 205 through a threaded connection ring, and the upper...

Embodiment 2

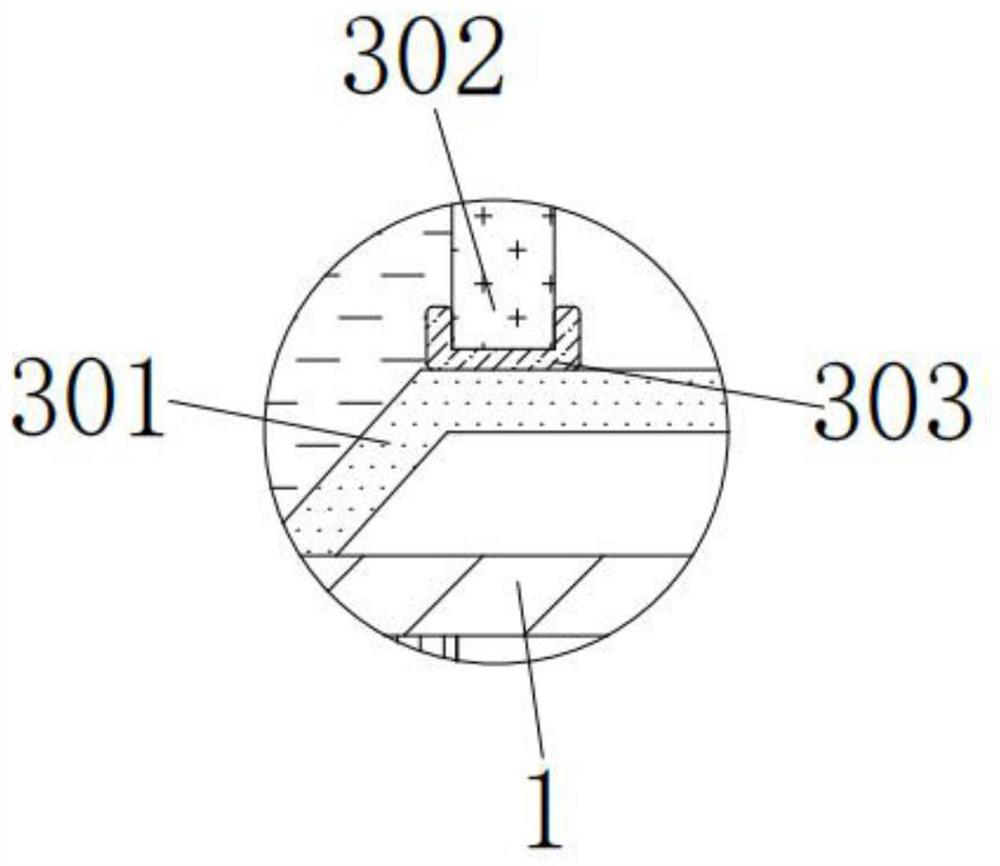

[0038] see Figure 1-7 , the invention provides a technical solution: a lifting type plant extract distillate layered separation system, including a first box 1, a base 2 and an outlet pipe 6, an opening is opened on the upper left side of the first box 1, and the first Three water outlet pipes 6 are fixedly connected inside the left side of the box body 1, and a valve is installed on the front end of the water outlet pipe 6, and a layering device 3 is installed inside the first box body 1, and the layering device 3 includes a trapezoidal plate 301, a second A vertical plate 302, a rubber pad 303, a cross bar 304, a first stop 305, a second box 306, a first spring 307 and a second stop 308, the outer wall of the trapezoidal plate 301 is fixedly connected with the first box 1, A first vertical plate 302 is installed above the trapezoidal plate 301, rubber pads 303 are fixedly attached to the outer walls of the upper and lower sides of the first vertical plate 302, and the outer...

Embodiment 3

[0040] As an option, see figure 1 and 4 , plant extraction distillate layered separation system, the right inner wall of the first box body 1 is equipped with a power unit 4, the power unit 4 includes a second vertical plate 401, a gear 402, a first connecting rod 403, a third vertical plate 404, The fifth vertical plate 405, motor 406 and threaded rod 407, the right side of the second vertical plate 401 up and down is fixedly connected with the first box body 1, and the left side of the rear end surface of the second vertical plate 401 is connected with a gear 402 through a rotating shaft. 402 can rotate at the second vertical plate 401 through the rotating shaft. The front end of the rotating shaft of the gear 402 is fixedly connected with the first connecting rod 403. The gear 402 can drive the first connecting rod 403 to rotate through the rotating shaft. The left side is connected with the third vertical plate 404 through the rotating shaft, the upper surface of the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com