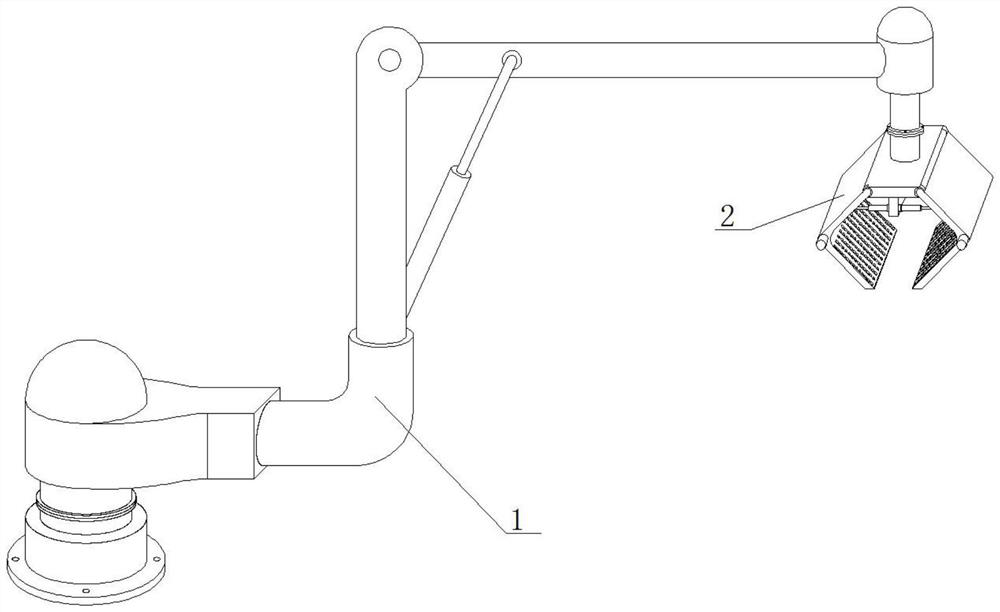

Stacking robot with sorting function

A technology of robots and function codes, applied in the direction of manipulators, manufacturing tools, stacking of objects, etc., can solve problems such as unfavorable stacking, skewed bagged goods, and reduced stacking efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

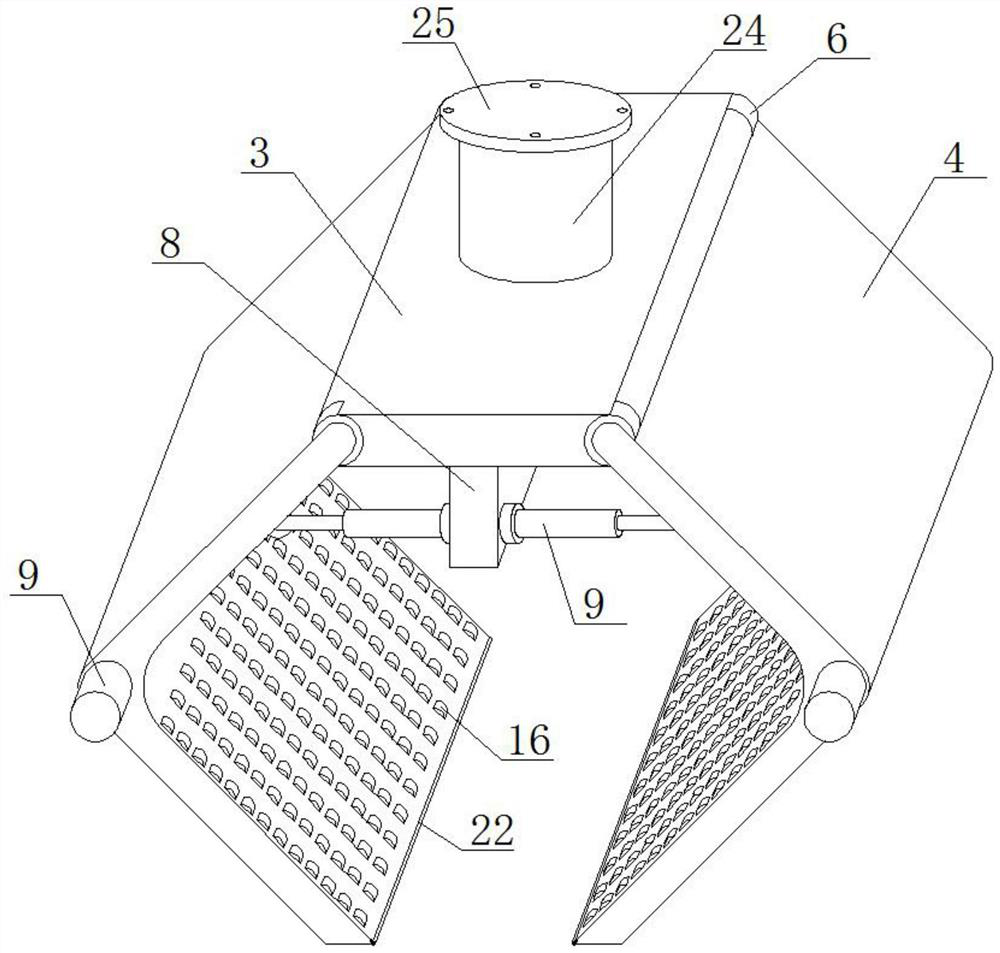

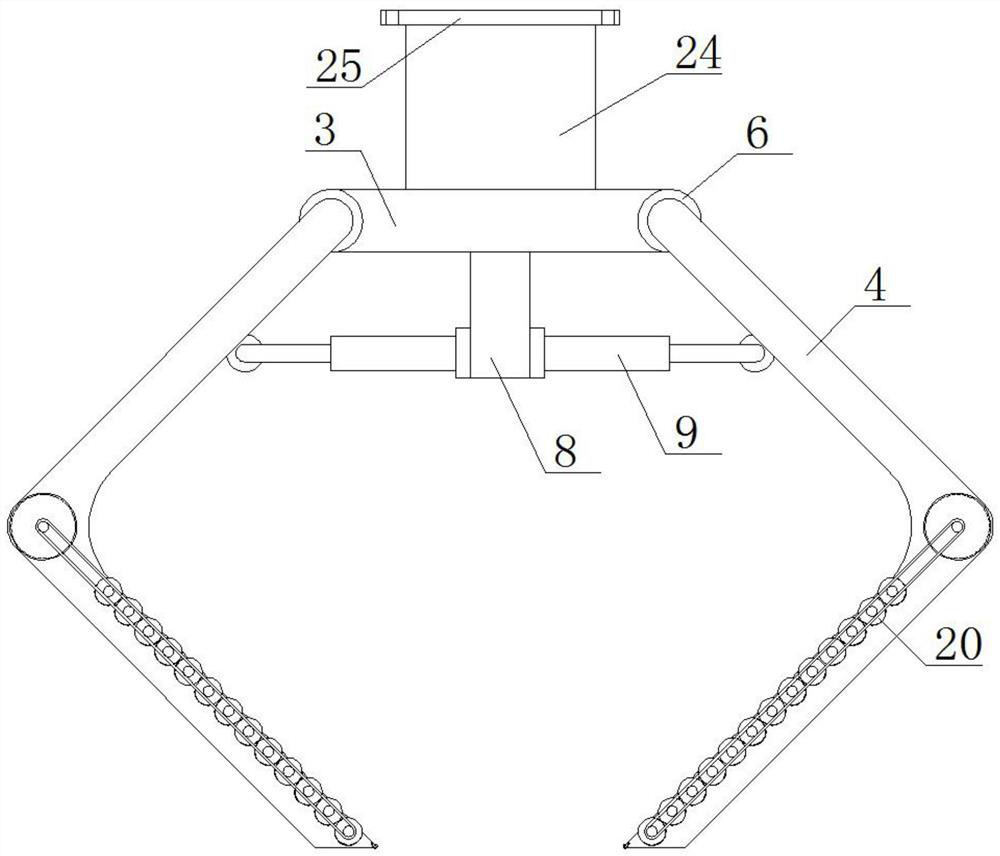

[0029]As a preferred embodiment of the present invention, a drive chain 19 is sheathed on the driving gear 13 and the dial gear 17, and there are openings between the driving gear chamber 11 and the dial chamber 14 and between each dial chamber 14. There is a chain hole, the transmission chain 19 is in the chain hole, the driving gear 13 and dial gear 17 are all meshed with the transmission chain 19, and each guide and toggle device 20 on the L-shaped clamping plate 4 passes through the same Driven by the driving gear 13 on the gear lever 12, each guide and toggle device 20 can rotate synchronously, further avoiding the inclination of bagged goods.

[0030] As a preferred embodiment of the present invention, one end of the L-shaped clamping plate 4 is provided with an arc-shaped groove 23 at a position corresponding to the front anti-damage roller 22, and one side of the front anti-damage roller 22 is in an arc shape. In the groove 23, the front anti-damage roller 22 is at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com