Preparation method of enhanced polymer composite membrane preprocessed by reinforced weaving tube

A polymer and composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as reducing the formation of surface coupling layers and affecting the effect of pre-coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

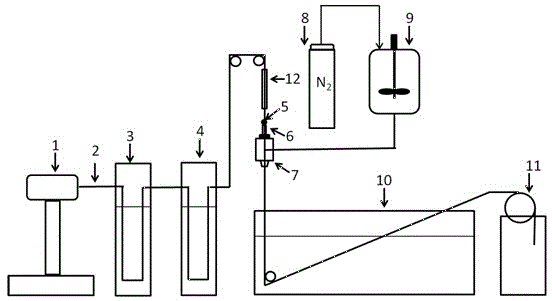

Method used

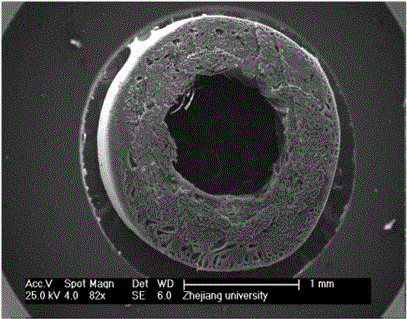

Image

Examples

Embodiment 1

[0030] 1) Add polyvinylidene fluoride (10% by mass), N-N dimethylacetamide (80% by mass), polyvinylpyrrolidone (9% by mass), and water (1% by mass) at 60°C Stir in the kettle for 6 hours, filter, vacuumize and stand still for degassing for 6 hours to obtain the casting solution;

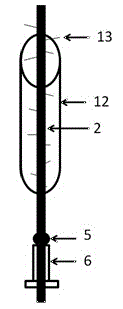

[0031] 2) Sintering of the woven tube: the hollow fiber woven tube (polyester braided tube, composed of 96 filaments, and the long fiber yarn is 200D) is passed through the sintering heating tube at a passing speed of 20 m / min, and the temperature of the sintering heating tube is 150 °C , the length of the sintered tube is 40 cm;

[0032] 3) Soak the sintered polyester woven tube in 10% N,N-2 methylformamide solution for 1 second to elute the chemical additives on the surface, and the elution temperature is 20°C;

[0033] 4) Pre-coat the surface of the eluted woven tube with a trifluoropropyltrimethoxysilane solution with a mass fraction of 10%, the pre-coating temperature is 20°C, and the coating t...

Embodiment 2

[0038] 1), polyethersulfone (mass percentage 25%), sulfolane and triacetin mixed solvent (mass percentage 60%, the mass ratio of the two is 4:3), polyethylene glycol (mass percentage 10%), propane Triol (5% by mass), stirred in a feeding kettle at 100°C for 18 hours, filtered, vacuumed, kept warm and static for 24 hours to obtain the casting solution;

[0039] 2) Sintering of the woven tube: the hollow fiber woven tube (which is a glass fiber braided tube, composed of 48 fiber filaments, and the long fiber yarn is 100D) passes through the sintering heating tube at a passing speed of 2 m / min, and the temperature of the sintering heating tube is 250 ℃, the length of the sintered tube is 10 cm;

[0040] 3) Soak the sintered polyester woven tube in 50% N,N-2 methylacetamide solution for 20 seconds to elute the chemical additives on the surface, and the elution temperature is 30°C;

[0041] 4) Pre-coat the surface of the eluted woven tube with a 2% perfluorooctylethyltrimethylsila...

Embodiment 3

[0046] 1), polyvinyl chloride (20% by mass), N-N dimethylacetamide (75% by mass), polyvinylpyrrolidone (2% by mass), ethylene glycol (3% by mass), at 65°C Stir in the feed kettle for 8 hours, filter, evacuate, keep warm and stand still for degassing for 8 hours to obtain the casting solution;

[0047] 2) Sintering of the woven tube: the hollow fiber woven tube (a nylon knitted tube, composed of 12 filaments, and the long fiber yarn is 50D);

[0048] Through the sintered heating tube, the passing speed is 10 m / min, the temperature of the sintered heating tube is 210°C, and the length of the sintered tube is 20 cm;

[0049] 3) Soak the sintered polyester woven tube in 30% sulfolane solution for 10 seconds to elute the chemical additives on its surface, and the elution temperature is 30°C;

[0050] 4) Pre-coat the surface of the eluted woven tube with a solution of polymethyl methacrylate with a mass fraction of 5%, the pre-coating temperature is 30°C, and the coating time is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com