Circuit breaker arc-extinguishing chamber

A technology of arc extinguishing chamber and circuit breaker, which is applied in the direction of circuits, electrical components, electric switches, etc. It can solve the problems of affecting the resistance and service life of circuit breakers, affecting the service life of arc extinguishing chambers, and poor impact resistance of arc extinguishing chambers. Achieve the effects of convenient and quick assembly, enhanced work stability, and improved arc extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will now be described in further detail in conjunction with the accompanying drawings.

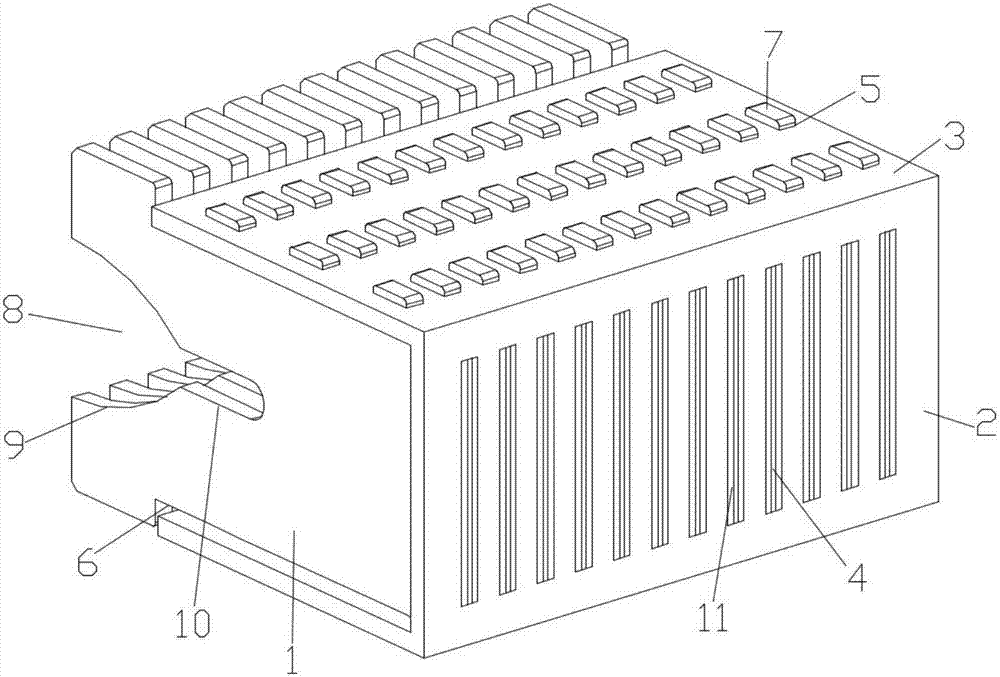

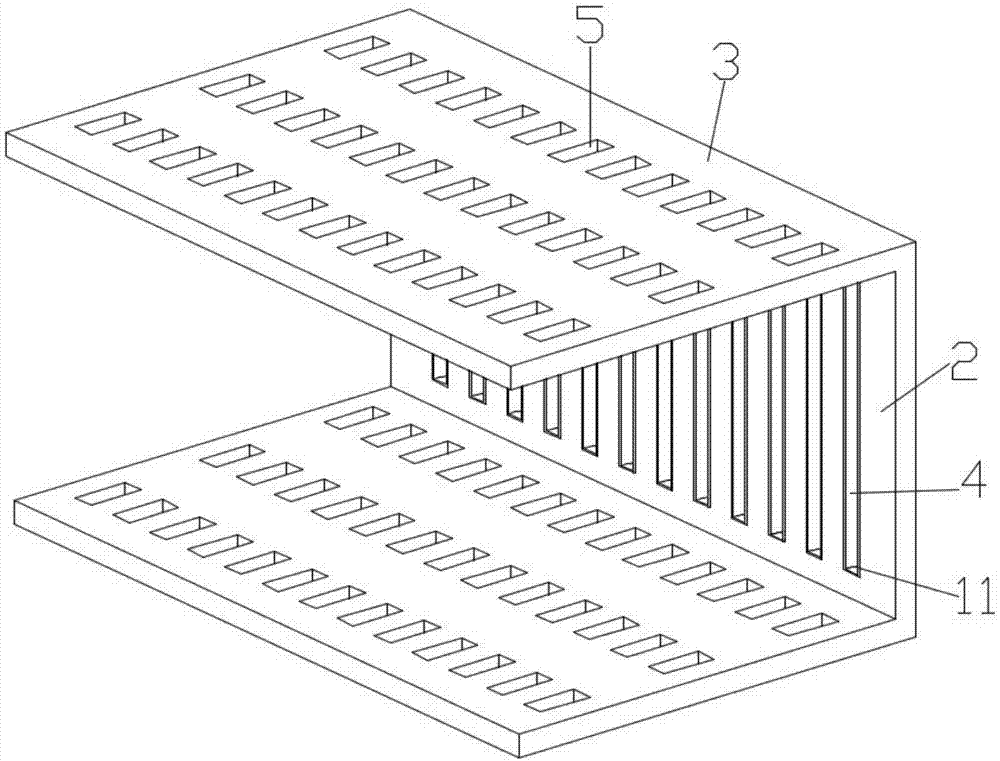

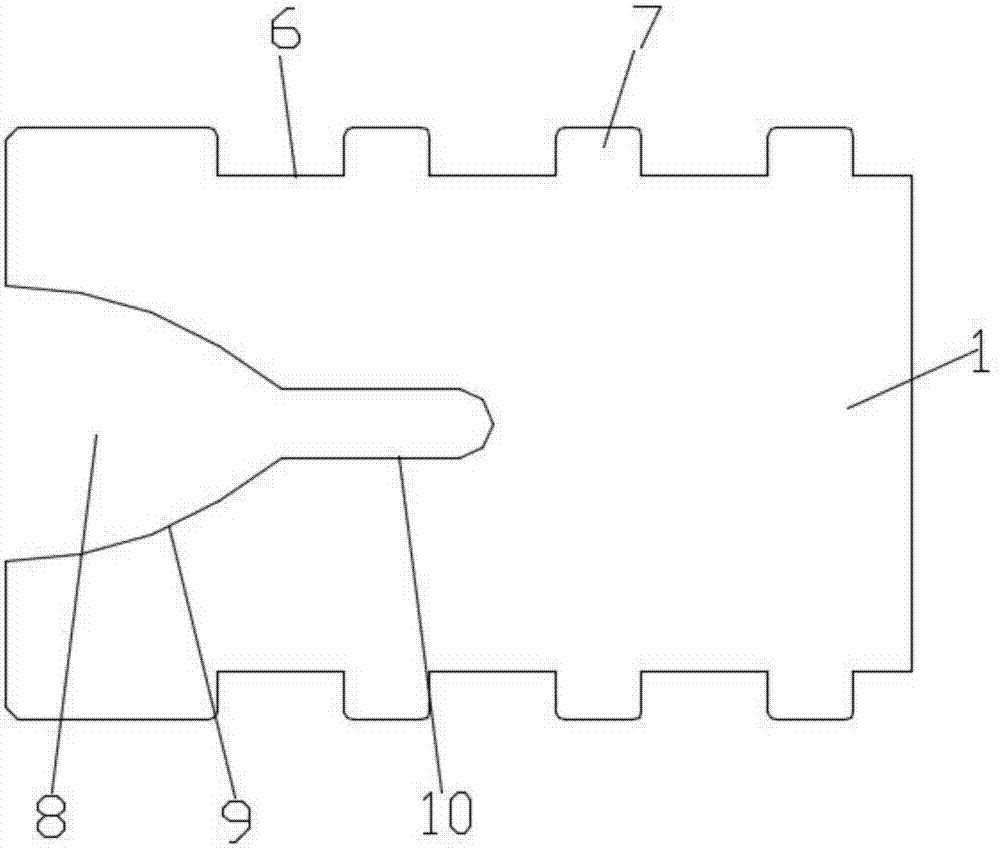

[0025] Such as Figure 1 to Figure 5 As shown, an arc extinguishing chamber for a circuit breaker includes a fixed plate and several parallel arc extinguishing grids 1 arranged in the fixed plate. The fixed plate includes a bottom plate 2 and two symmetrically arranged Side plate 3, several exhaust passages 4 are evenly distributed along the length direction of the bottom plate 2 on the bottom plate 2, and several sets of fixing mechanisms are evenly distributed along the length direction of the side plate 3 on the side plate 3, the The projections of the exhaust channel 4 and the fixing mechanism in the direction of the bottom plate 2 or the projection in the direction of the side plate 3 are sequentially staggered, and the fixing mechanism includes several fixing holes 5 evenly distributed along the width direction of the side plate 3, Two opposite side ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com