Anti-Loose Fastener Assembly

A fastener and anti-loosening technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of disappearance, reduced friction between the nut and the workpiece, loosening of the anti-loosening structure, etc. The effect of preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

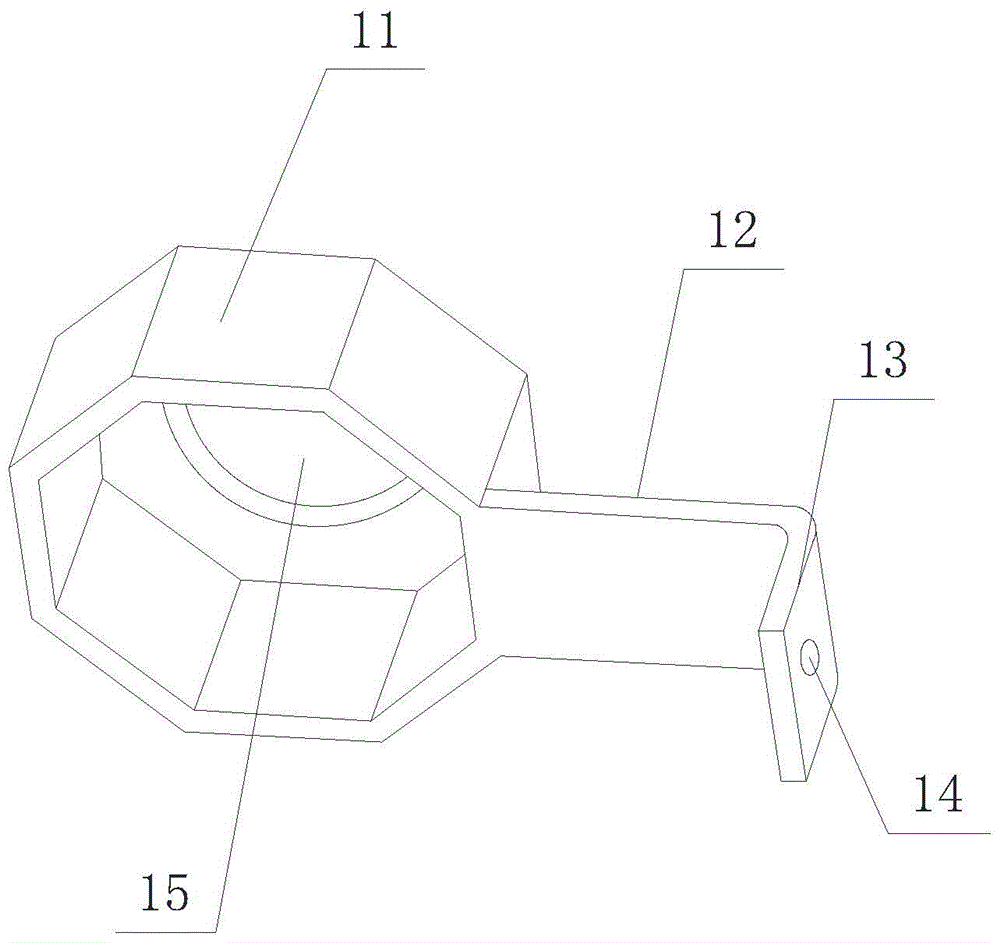

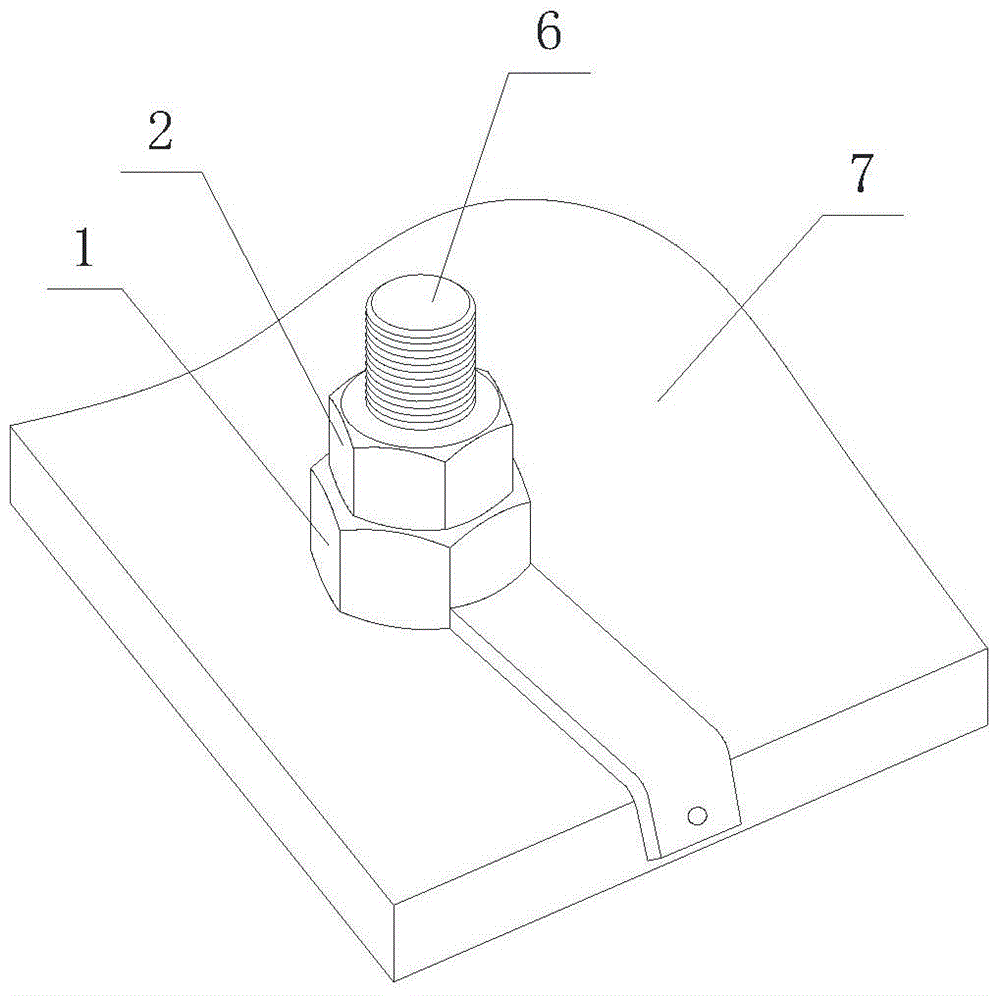

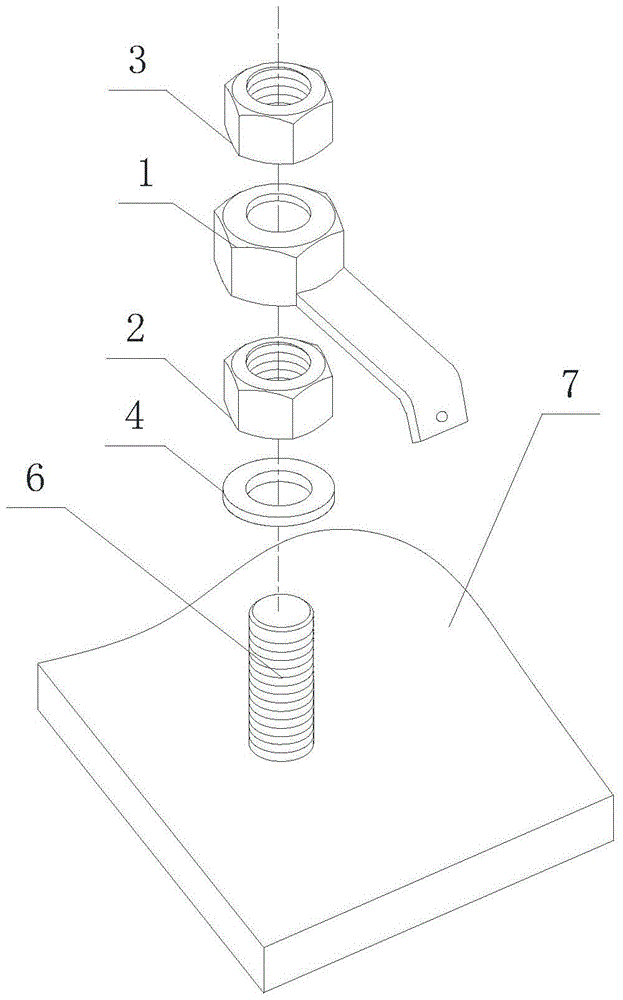

[0018] Example: see figure 1 , figure 2 , image 3 and Figure 4 , an anti-loosening fastener assembly, including a bolt 6 and a nut that cooperates with the bolt 6 to limit the workpiece 7, and the number of nuts that cooperate with the bolt 6 on the same side as the workpiece 7 is at least two, including the nut that cooperates with the workpiece 7 The lower nut 2 that is in contact with the upper nut 3 that limits the position of the lower nut 2 is provided with a positioning cap 1 that limits the position of the lower nut 2 between the two nuts, and the positioning cap 1 is set on the lower nut 2 Above, the positioning cap 1 includes a cap 11 matched with a corresponding nut, and a bent buckle connected to the cap 11 for buckling the edge of the workpiece 7 .

[0019] As a preference, the cap 11 is open at one end and closed at the other end, and the internal shape of the opening matches the shape and size of the restricted lower nut 2, and the middle part of the close...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap