Anti-disengaging detachable material returning air cap for circulating fluidized bed boiler

A circulating fluidized bed and anti-shedding technology, which is applied in the direction of fluidized bed combustion equipment, fuel burned in molten state, combustion type, etc., can solve problems such as unusable cylindrical structure, affecting the normal operation of the feeding device, loose threads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

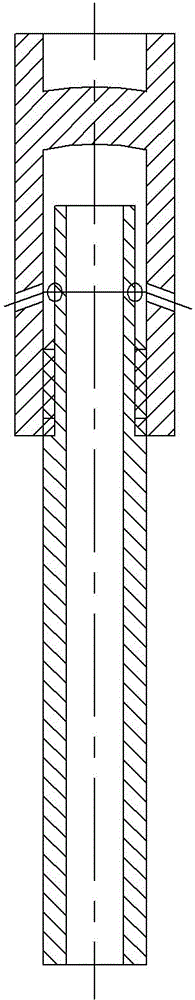

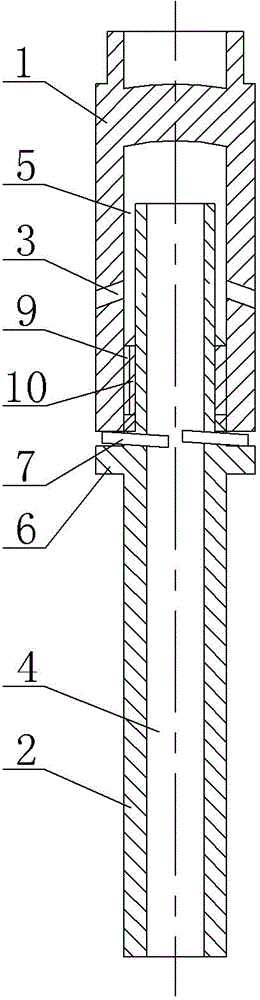

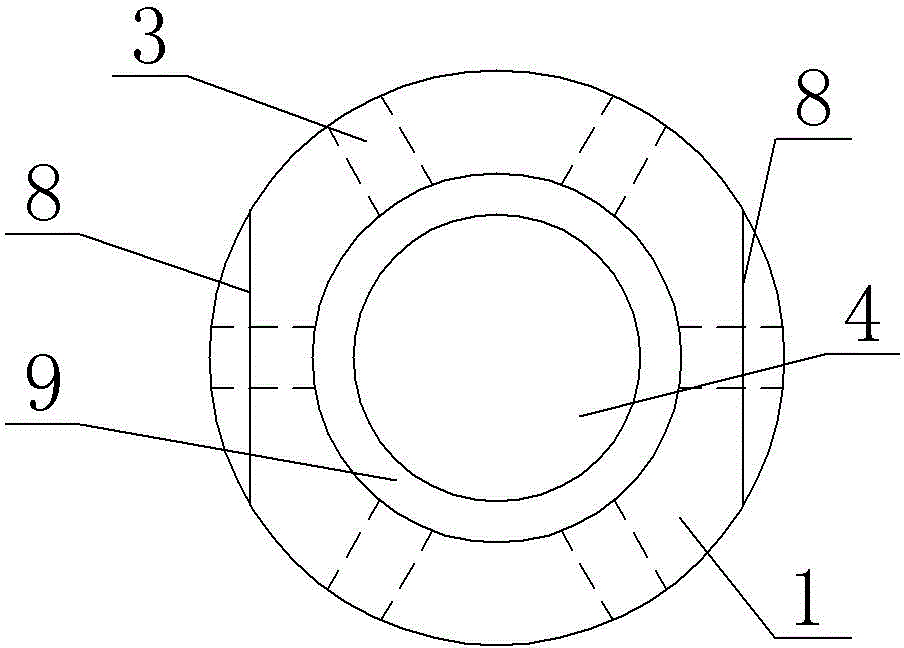

[0010] See Figure 2 ~ Figure 3 , which includes a hood head 1 and a hood connecting pipe 2, the lower end of the hood head 1 is threadedly connected to the upper joint of the hood connecting pipe 2, the central annular surface of the hood head 1 is provided with an air outlet 3, and the central hole 4 of the hood connecting pipe 2 is connected to the hood head 1. The cavity 5 formed by the combination of the hood adapter 2, the cavity 5 is connected to the air outlet 3, the middle part of the hood adapter 2 is provided with an outer boss structure 6, the upper end surface of the outer boss structure 6 is a flat structure, the bottom of the hood head 1 A spring washer 7 is pressed between the end face and the upper end face of the outer boss structure 6 , and the two sides of the outer ring surface of the hood head 1 corresponding to the threaded part are processed into a planar structure 8 .

[0011] The inner ring surface of the lower end of the hood head 1 is welded with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com