Splicing frame for video wall display units, and video wall

A display unit and video wall technology, applied in rack/frame structure, instruments, identification devices, etc., can solve the problems of reducing the area of the display area and affecting the transparent display effect of the video wall, so as to optimize the splicing structure and improve the display effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

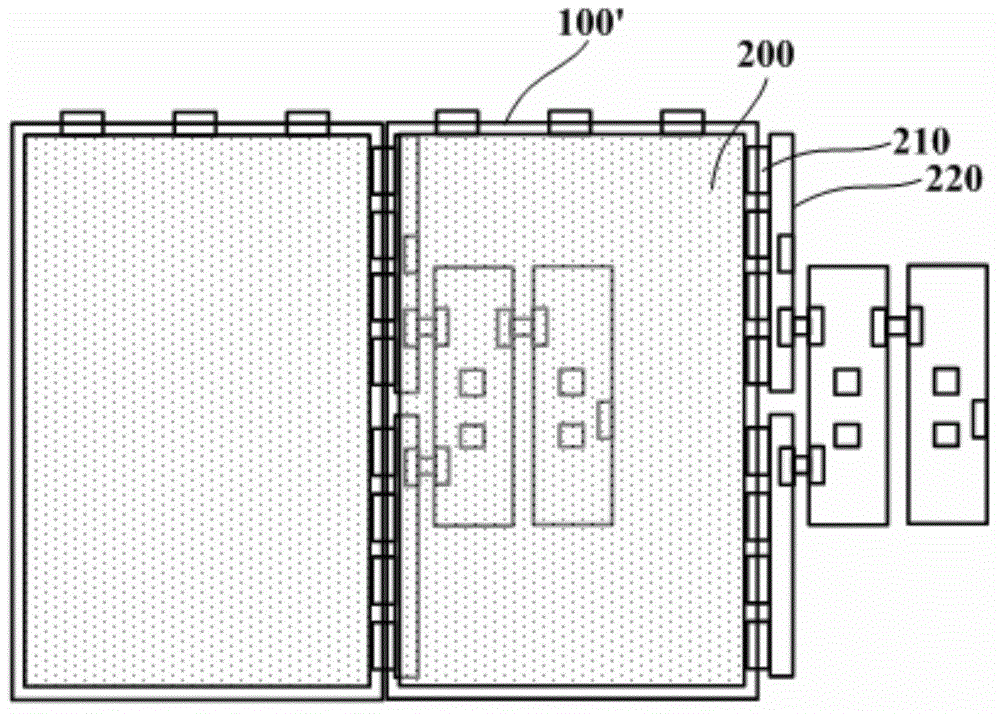

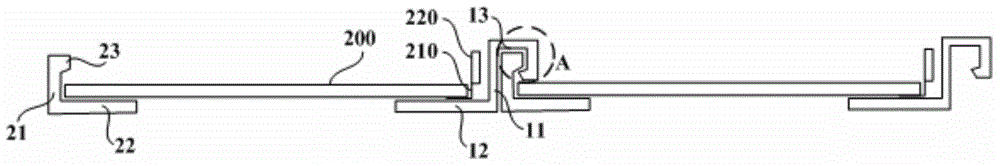

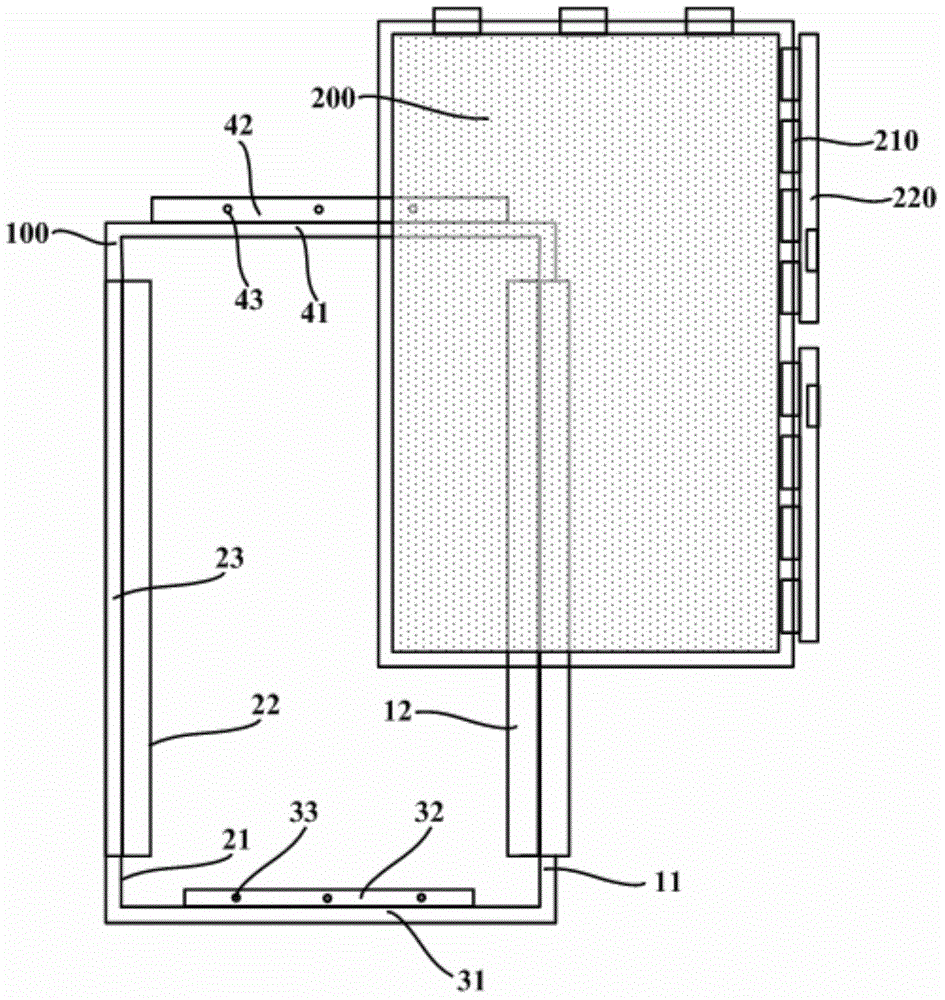

[0031] In order to reduce the area overlap between the chip-on-film board and the printed circuit board and the adjacent display unit, and optimize the splicing structure of the video wall, an embodiment of the present invention provides a splicing frame of the display unit of the video wall and a video wall. In the technical solution of the present invention, the chip-on-chip film board and the printed circuit board of the display unit can be folded between the display unit body and the first side plate, and the chip-on-chip film board and the printed circuit board will not be adjacent to the first splicing direction. The area of the display unit overlaps, which greatly optimizes the splicing structure of the video wall. When the splicing frame is applied to the video wall with a transparent display effect, the chip-on-film board and the printed circuit board are invisible, so compared with the existing technology, it can improve The display effect of the video wall.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com