Ground brush of dust collector

A vacuum cleaner and scraper technology, applied in the directions of suction nozzles, suction hoses, etc., can solve the problems of poor cleaning ability of vacuum cleaners, obstructing the entry of garbage into the air inlet, and the inability to collect and clean the garbage, and achieve the effect of improving the cleaning ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

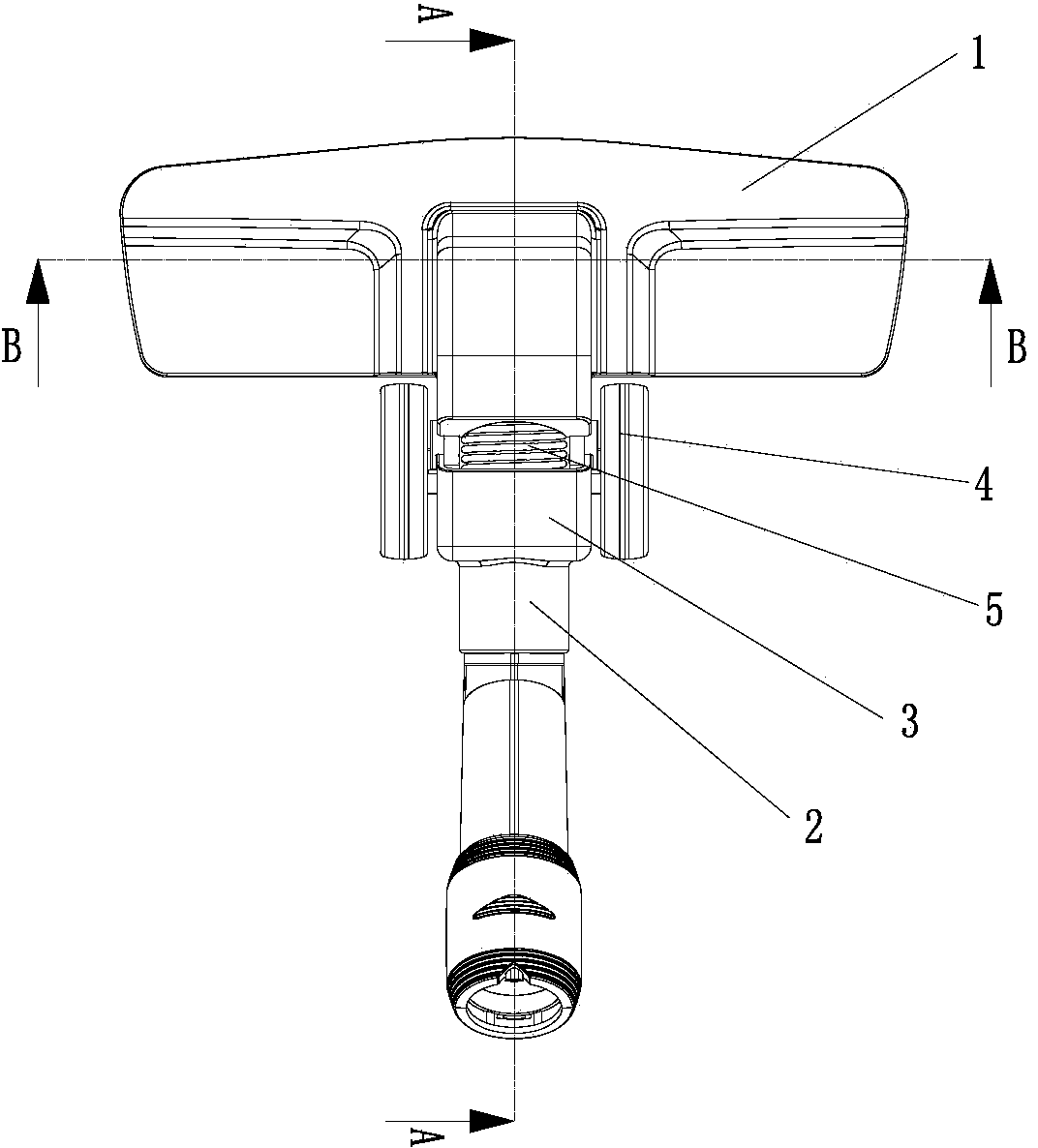

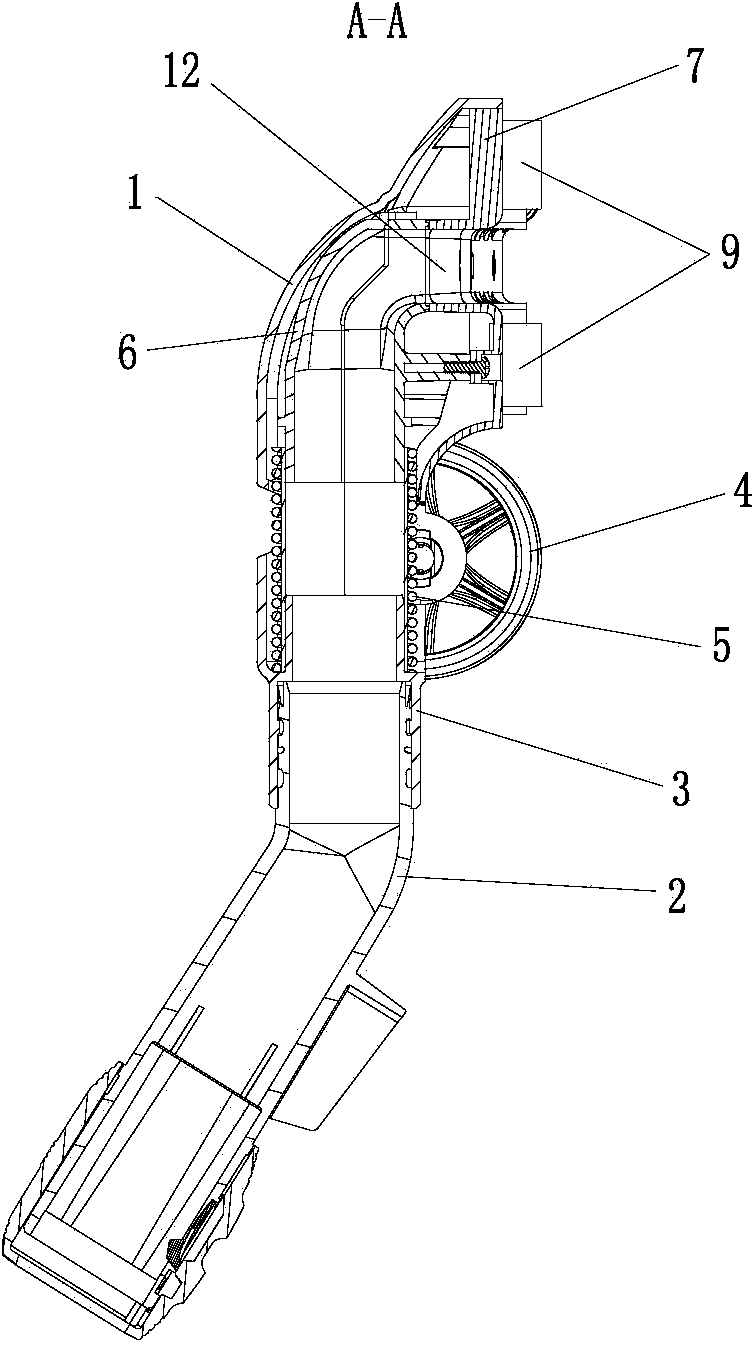

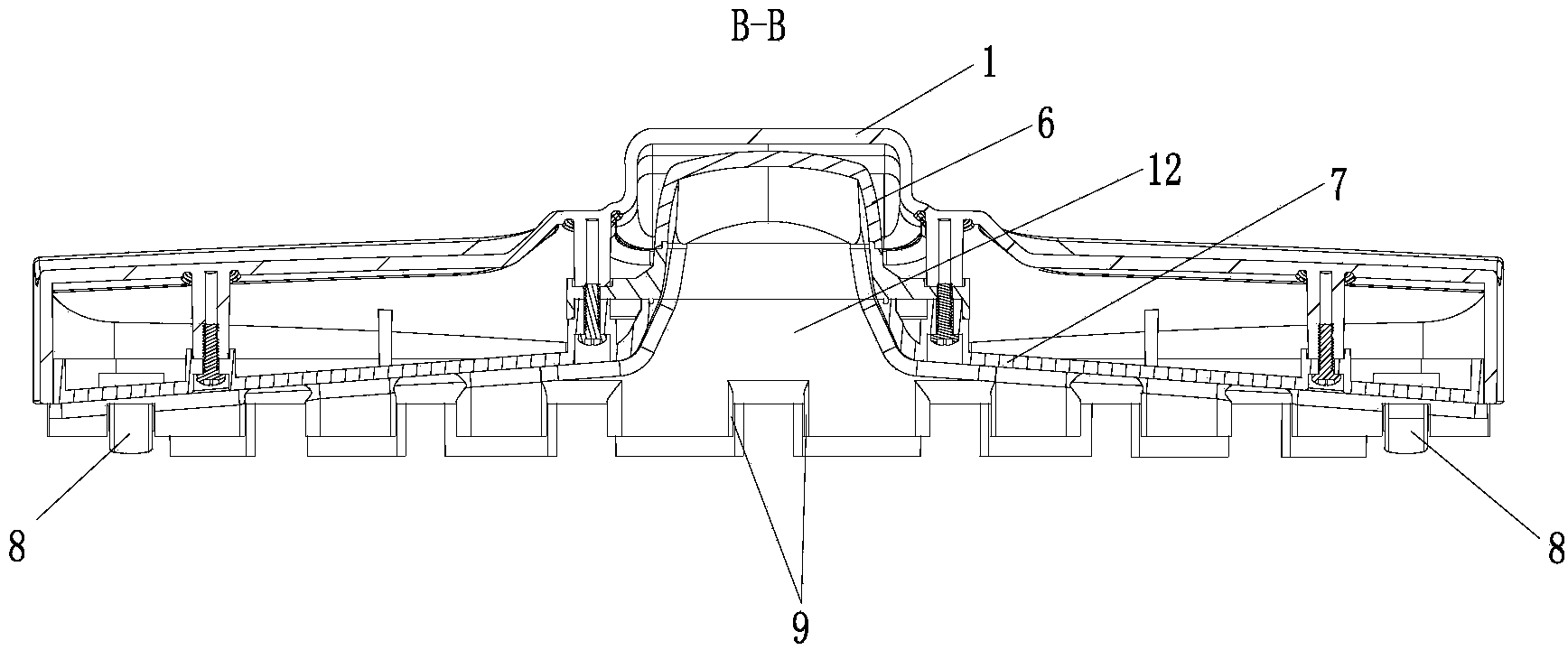

[0024] Such as Figure 1~5 As shown, a vacuum cleaner ground brush includes a housing composed of an upper cover 1 and a bottom cover 7 with an air intake passage 12, and an elbow joint 2 arranged at the rear end of the housing. The upper cover 1 and the bottom cover 7 are fixed by bolts connection, the air inlet passage 12 includes an air inlet and an air outlet 10, the air outlet 10 communicates with the lumen of the elbow joint 2, and the bottom cover 7 is fixed with a scraper structure, and the scraper structure includes There are multiple scraper units on both sides, there are 4 specific scraper units, and the 4 scraper units are symmetrically arranged on the front and rear sides of the air inlet, among which, the two scraper units arranged on the front side of the air inlet The center line of the length direction of the bottom cover 7 is symmetrically arranged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com