Precast unit top-bottom forming mold closing mechanism and closing and opening method thereof

A technology of prefabricated components and mold clamping mechanism, applied in the direction of molds, etc., can solve the problem of fast mold closing or opening of the pipe pile forming mold, and achieve the effects of high reliability, unique structure and high safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

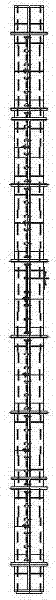

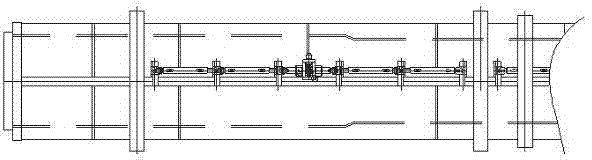

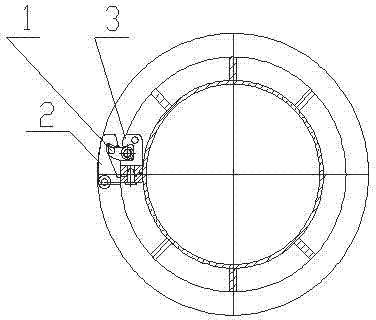

[0015] Embodiment 1: with reference to attached Figure 1-7 . A prefabricated component forming mold upper and lower mold clamping mechanism, including an upper mold, a lower mold and a controller, a plurality of upper mold locking blocks 3 are fixed on the wall above the opening and closing die opening of the upper mold, and a plurality of upper mold locking blocks 3 and a plurality of lower die locking blocks 2 fixed on the lower wall of the opening and closing die opening of the lower die form a locking port, and the left and right screw rods 9 and 10 are respectively located at the ends of the multi-block upper die locking blocks 3 through the screw rod support ears. In the locking groove, a plurality of movable locking blocks 1 are fixed on the left and right screw rods 9 and 10, and the plurality of movable locking blocks 3 fixed on the left and right screw rods 9 and 10 are respectively locked with the corresponding multi-piece upper molds. The locking opening formed b...

Embodiment 2

[0016] Embodiment 2: On the basis of Embodiment 1, a mold clamping and mold opening method for the upper and lower mold clamping mechanisms of the prefabricated component forming mold. 3. The locking opening is opposite to the hook openings of multiple lower die locking blocks 2 located on the lower wall of the lower die opening and forms a locking opening. At this time, the controller instructs the driving mechanism to drive the worm wheel 4 to rotate, and the worm gear 4 drives the worm 5, and the worm 5 Drive the left and right screw rods 9 and 10 to move left or right, and the screw rods 9 and 10 drive the multiple movable locking blocks 1 fixed on them to enter synchronously into the locking ports of multiple upper die locking blocks 3 and multiple lower die locks. When the locking mouth of the tight block 2 is opposite to the locking mouth (the controller can calculate the moving distance of the movable locking block 1 driven by the screw by calculating the number of rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com