Fabrication and installation of pre-buried shear grooves in ultra-deep underground diaphragm walls

An underground diaphragm wall and construction method technology, applied to artificial islands, sheet pile walls, water conservancy projects, etc., can solve problems such as easy breakage or displacement, difficulty in digging out, and difficulty in installation and fixing, and achieves convenient removal and remarkable The effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

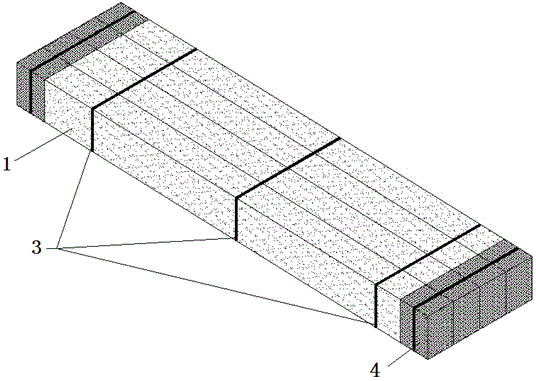

[0024] The embodiments of the present invention will be described in detail below in conjunction with the drawings:

[0025] A construction method for the fabrication and installation of embedded shear troughs for ultra-deep underground continuous walls mainly includes:

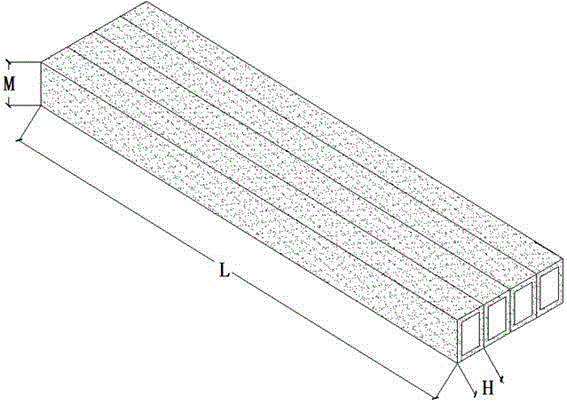

[0026] (1) Selection and production of materials for embedded shear grooves

[0027] According to the design requirements of the cross-section size of the shear groove, choose a PVC square pipe with a cross-section size of 100mm (width) × 70mm (height) and a wall thickness of 5mm. The length of a single root is customized to 5m, 5.5m, Three kinds of 6m. The material requirements of the PVC square pipe: small linear expansion coefficient, low thermal conductivity and elastic modulus, easy to store in reinforced concrete, and high hardness and compressive strength, easy to resist aging, acid, alkali and salt corrosion.

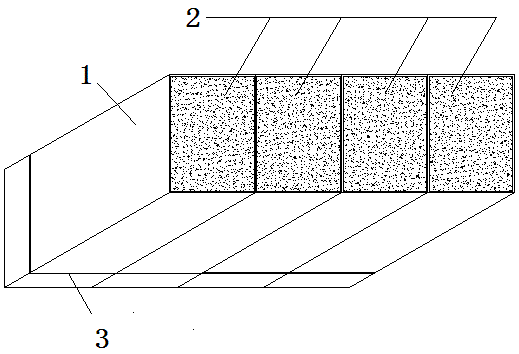

[0028] (2) Assembled and combined form of embedded shear trough-PVC square pipe

[0029] The cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com