Fork Arm Glass Lifter Final Inspection Station Equipment

A glass lifter and wishbone technology, which is applied in the field of auto parts manufacturing equipment, and can solve problems such as glass lifters that do not yet exist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

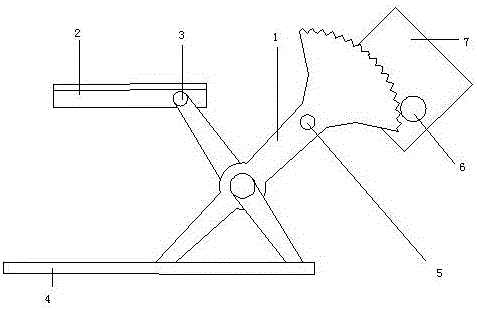

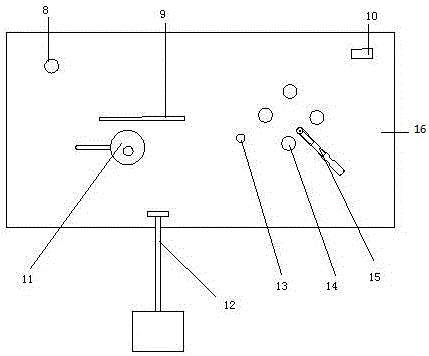

[0012] refer to figure 2 , The final inspection platform equipment of the wishbone type glass regulator of the present invention includes a workbench 16 , a chute bar 9 , a rotating shaft support point 13 , a power module support point 14 and a quick clamp 15 . control figure 1 It can be seen that the position of the chute clip 9 corresponds to the chute 2 of the wishbone glass regulator, the position of the rotating shaft supporting point 13 corresponds to the rotating shaft 5, the position of the power module supporting point 14 corresponds to the power module 7, and the position of the quick clip 15 The position corresponds to the output shaft 6 . An eccentric wheel 11 is arranged below the chute clip 9. During detection, the chute 2 of the wishbone glass regulator is stuck between the chute clip 9 and the eccentric wheel 11, and the eccentric wheel 11 can be m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com