Description method of lighting source for lithography machine

An illumination light source and lithography machine technology, applied in the field of lithography machines, can solve the problems affecting the speed and quality of the lighting source optimization of the lithography machine, and achieve the effects of reducing the production cycle and time cost, reducing the quantity and increasing the speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

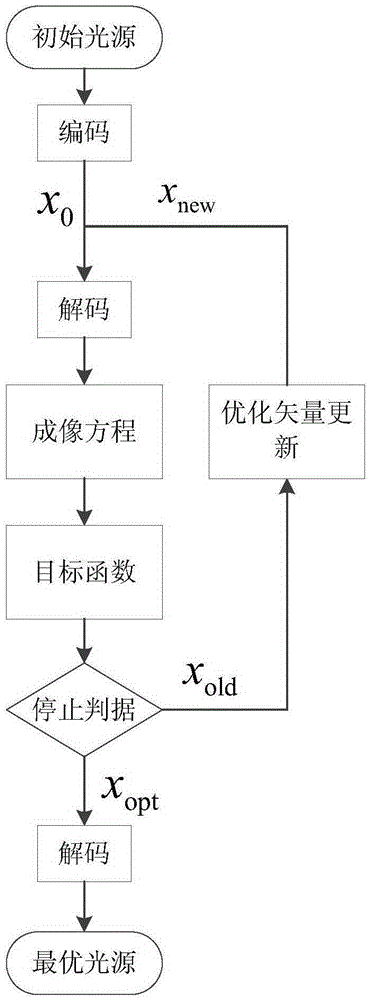

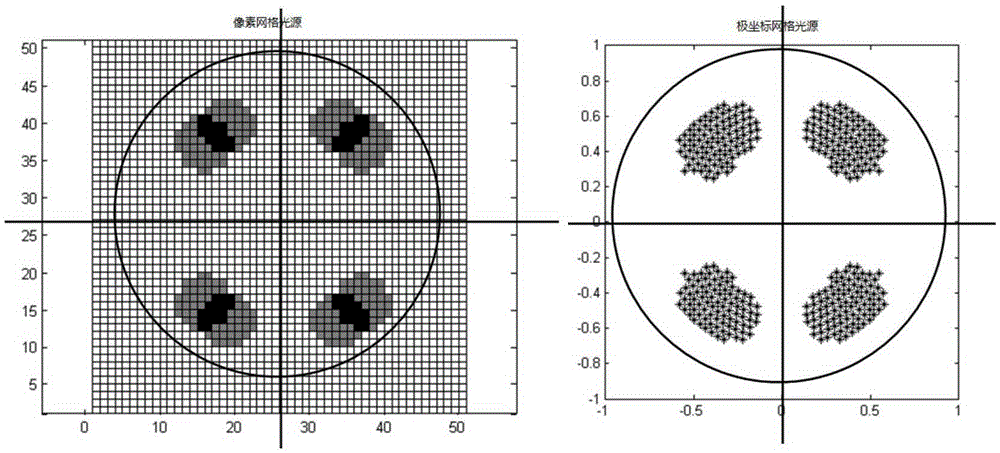

[0027] The method for describing the lighting source of the lithography machine according to the present invention is as follows: Figure 4 shown. Each circular sub-illumination source requires four parameters (r σ ,r,θ,g) description, where r σ is the radius of the sub-illumination light source, (r, θ) is the polar coordinate of the center of the sub-illumination light source, and g is the light intensity of the sub-illumination light source. The photolithography machine illumination light source in the embodiment consists of 20 radius r σ =0.05 of the sub-illumination light source (note: the maximum radius of the illumination source is 1), so the light source of the lithography machine can be described by the following vector,

[0028]

[0029] The total number N o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com