Explicit modularized socket

A modular, socket technology, applied in the direction of fixed/insulated contact members, electrical components, coupling devices, etc., can solve the problems of difficult automatic assembly, inconvenient assembly, and the hole type module cannot be used universally, so as to achieve the effect of convenient automatic production of sockets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

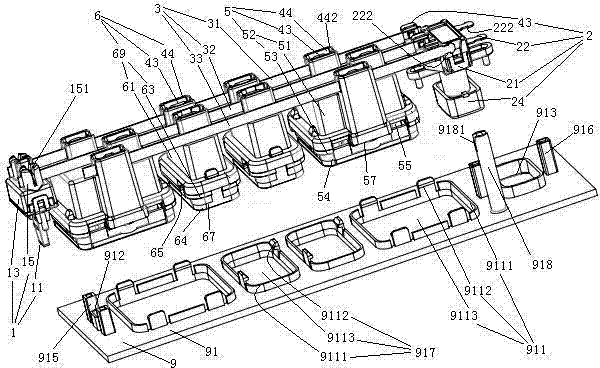

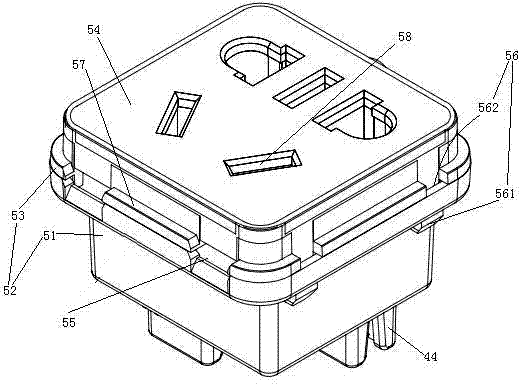

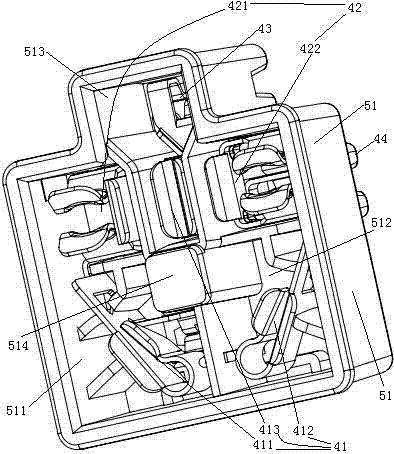

[0041] Embodiment one, see figure 1 , an explicit modular socket, including a socket shell 9, a socket conductive sheet 3, a five-hole hole module 5, a double-hole hole module 6, an electrical plug-in structure 7, an indicator light module 1 and a switch module 2.

[0042] The socket housing 9 includes a socket panel 91 and a socket bottom box (not shown in the figure). The socket panel 91 and the socket bottom box form a box body. The socket conductive sheet 3 , the five-hole hole module 5 , the double-hole hole module 6 , the indicator light module 1 and the switch module 2 are distributed on the same straight line and are all located inside the socket housing 9 . The socket panel 91 is provided with an indicator light window 912 , a switch module window 913 and several jacks 914 . There are 2 five hole pattern modules 5. There are 2 double-hole hole modules 6.

[0043] The socket conductive sheet 3 includes an N-pole socket conductive sheet 31 , an L-pole socket conduct...

Embodiment 2

[0082] Embodiment two, see Figure 17 , the difference with the first embodiment is: a socket electrical plug-in structure 7 is provided at the end of the two switch incoming terminals 22 and the conductive sheet of the E pole socket. The socket electrical insertion structure includes a body 71 . One end of the body 71 is provided with a slot 74 , and the other end is provided with a connecting piece 76 . The connecting piece 76 is a hoop. An end of the main body 71 away from the connecting member 76 is provided with a supporting piece 72 . A pressing piece 73 is provided on both sides of the supporting piece 72 . The pressing piece 73 and the supporting piece 72 are integrally structured. A slot 74 is formed between the pressing piece 73 and the receiving piece 72 . The pressing piece 73 includes a connecting wall 731 , a clamping wall 732 and a folded edge 733 arranged in sequence. The connecting wall 731 , the clamping wall 732 and the folded edge 733 are sheet metal ...

Embodiment 3

[0083] Embodiment three, see Figure 18 , the difference from the second embodiment is: the booster holes 79 are distributed on both sides of the clamping block 78 along the direction perpendicular to the extending direction of the slot 74 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com