Instrument panel cross member for a vehicle, made of fiber-reinforced plastic

A technology to strengthen plastics and instrument panels, applied in vehicle components, superstructure sub-assemblies, transportation and packaging, etc., can solve problems such as separate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

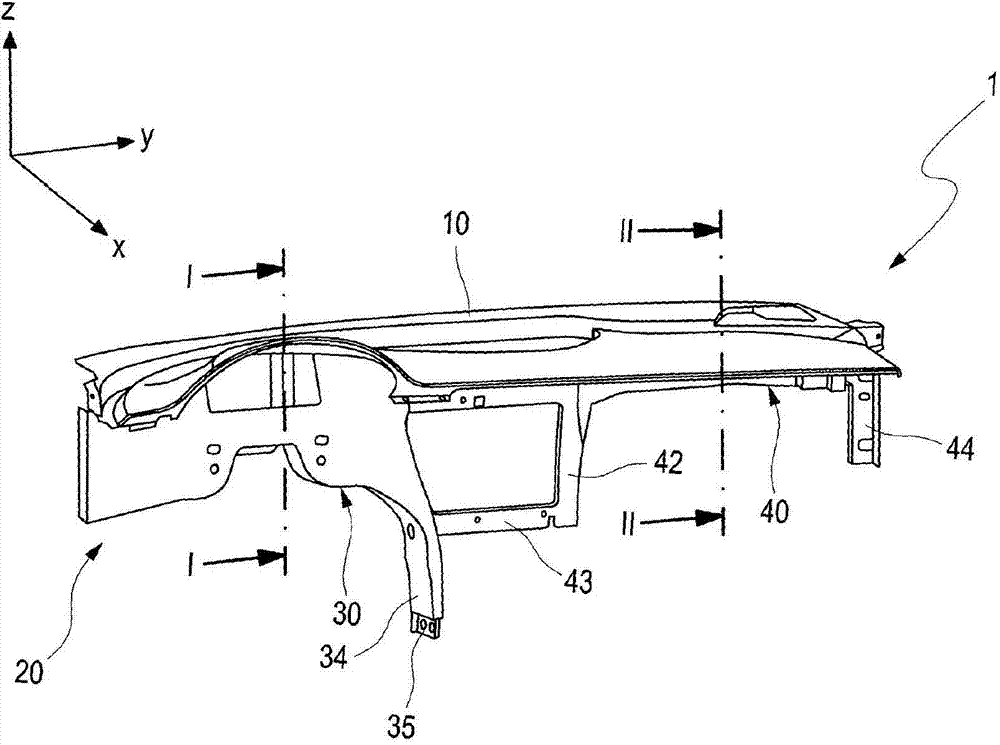

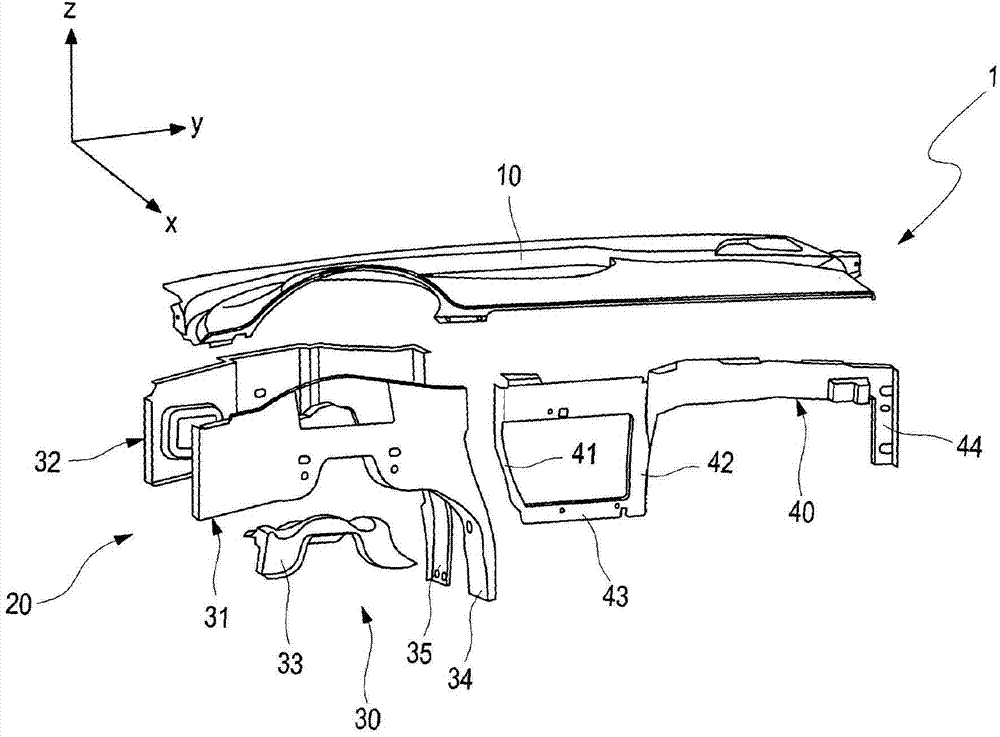

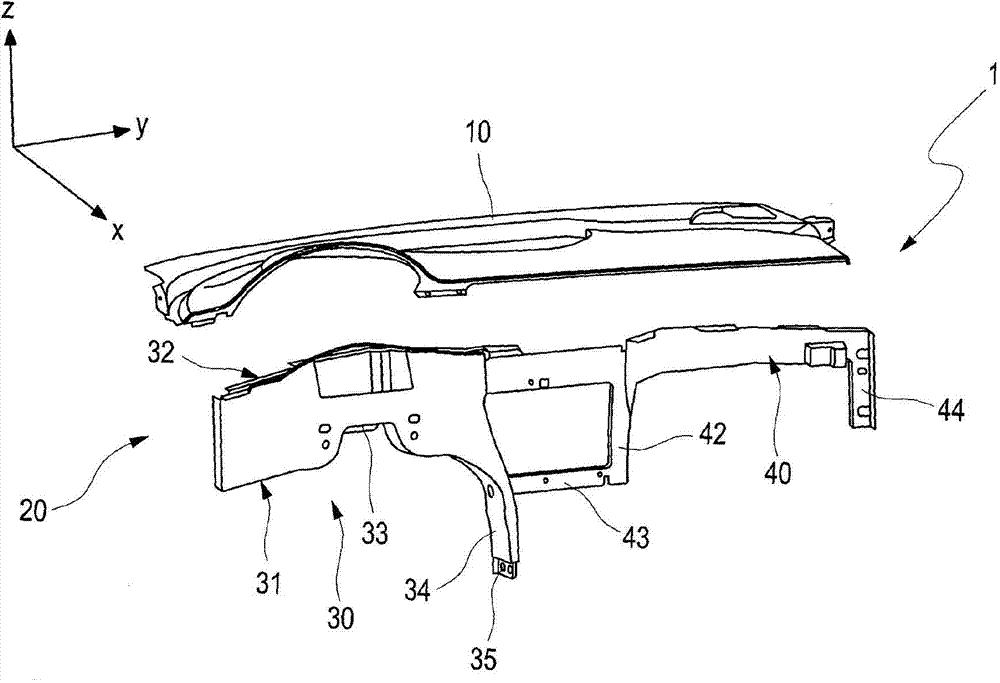

[0022] according to figure 1 , according to the present embodiment, the automobile instrument panel beam 1 includes an instrument panel 10 and a multi-piece modular beam 20, such as image 3 shown. All parts of the dashboard cross member 1 are made of composite material, for example carbon fiber reinforced plastic (CFK).

[0023] The multi-part modular beam 20 is mounted between two A-pillars of the motor vehicle, ie extends in the y-direction of the motor vehicle and according to figure 2 A first multi-piece beam member 30 and a second beam member 40 are included.

[0024] The first beam member 30 is composed of three parts, namely a shell-shaped front portion 31 , a shell-shaped rear portion 32 and a shell-shaped bottom portion 33 . These three parts 31, 32 and 33 are glued together by means of adhesive bonding under the situation of forming U-shaped profile respectively at the edge side, as by Figure 4 middle pair figure 1 As can be seen in the illustration of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com