Chestnut picking machine

A technology for picking machines and chestnuts, applied in the directions of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of waste, low work efficiency, increased weight of the whole machine, etc., and achieve convenient operation, practical functions and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

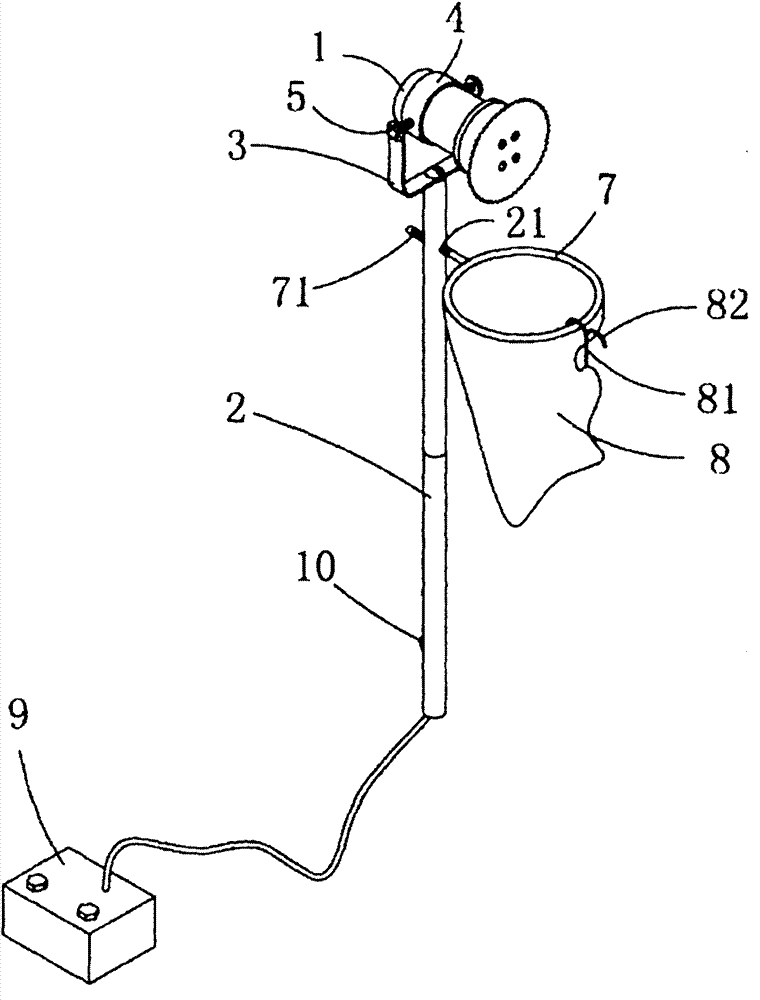

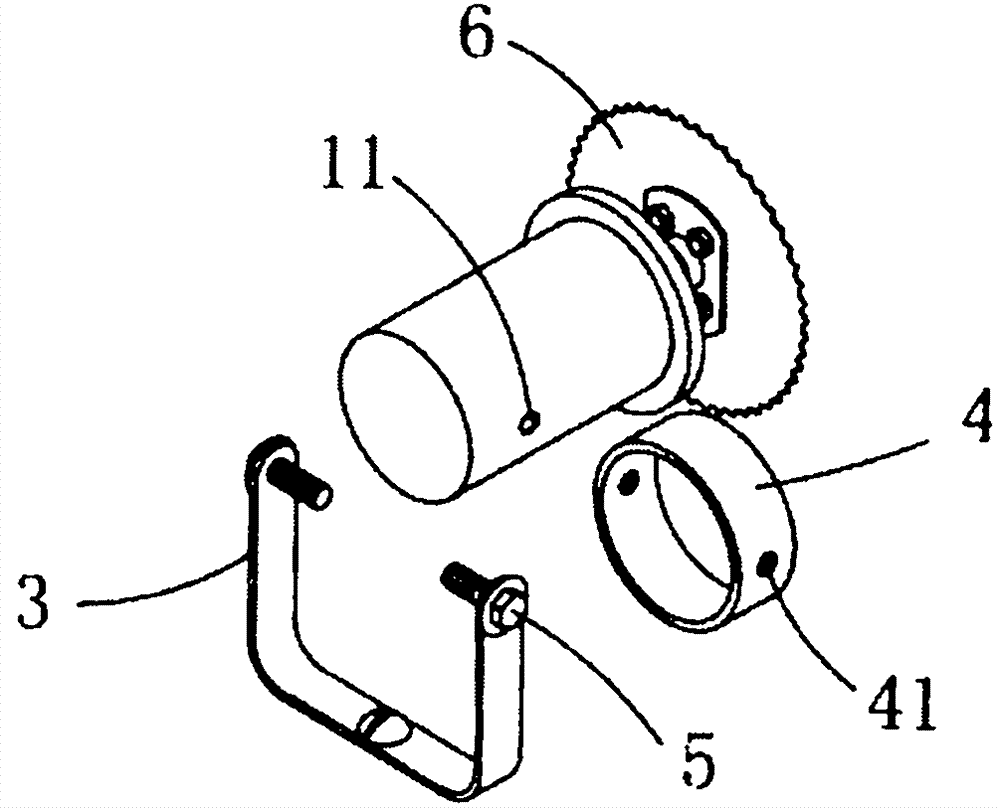

[0019] Such as Figure 1~3 Shown, a kind of chestnut picker comprises micromotor 1 and telescopic control link 2, and the top of control link 2 is provided with U-shaped support 3, and the two sides of micromotor 1 are symmetrically provided with threaded holes 11, and micromotor 1. The upper sleeve is provided with a fixed sleeve 4, and the first through hole 41 with an internal thread is arranged symmetrically on both sides of the fixed sleeve 4. The micro motor 1 passes through the U-shaped bracket 3, the first through hole 41, and the threaded hole through the bolt 5 in turn. 11 is fixed on the U-shaped bracket 3, and the output shaft of the micro-motor 1 is fixed with a circular saw 6. The diameter of the circular saw 6 is 12 centimeters, and the thickness of the circular saw 6 is 1 to 2 mm. 6 The rotating speed in the working state is 2000-2500 rpm.

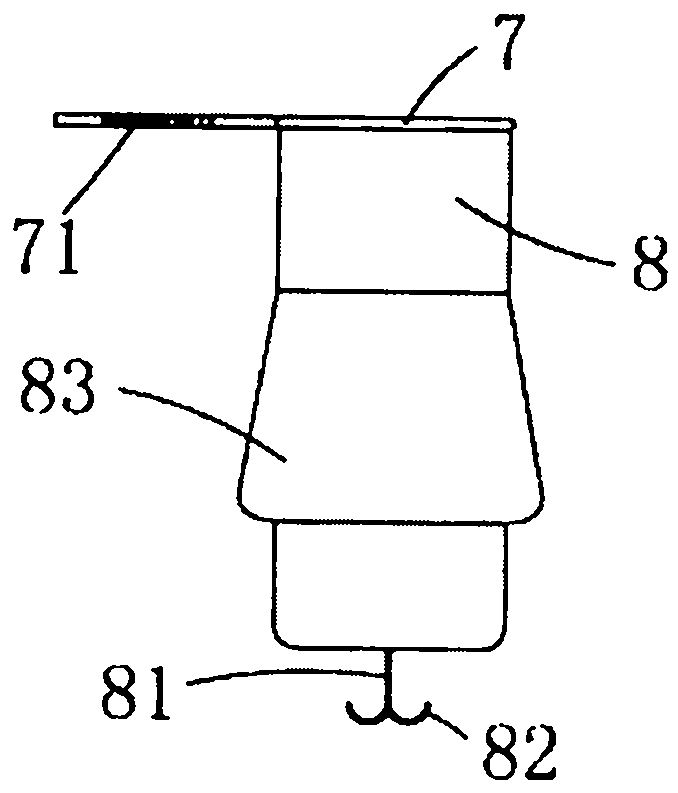

[0020] A support frame 7 and a storage bag 8 are arranged below the circular saw 6 . The support frame 7 is fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com