Mold for crocheting garment collar lapel and using method thereof

A collar and lapel technology is applied in the field of moulds for hooking garment collars to achieve the effects of straight stitches, improved stability and fixed intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

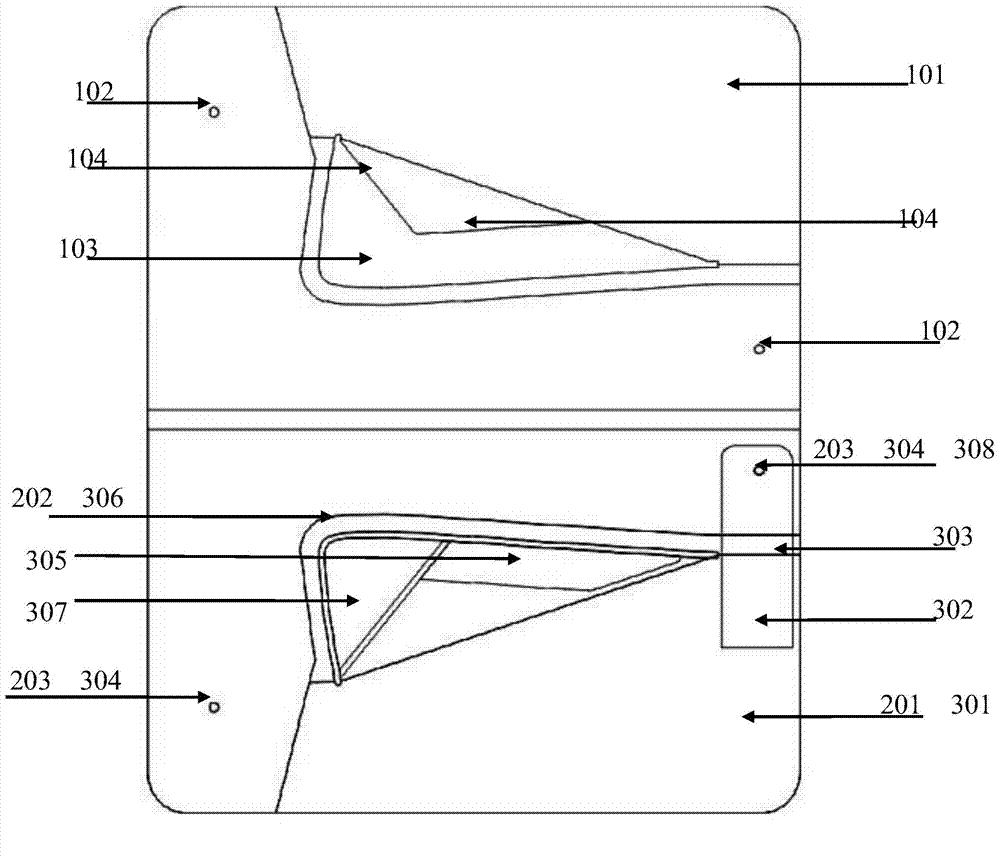

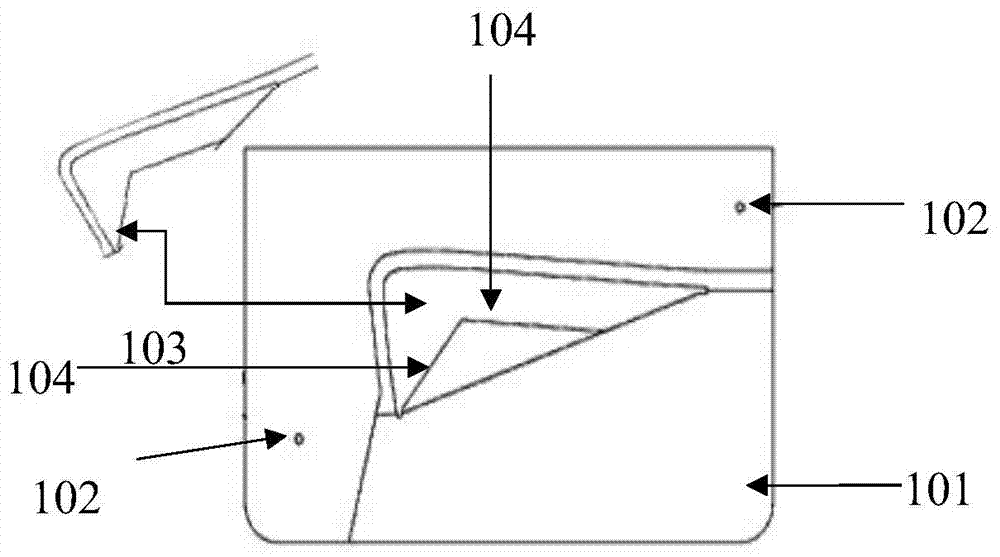

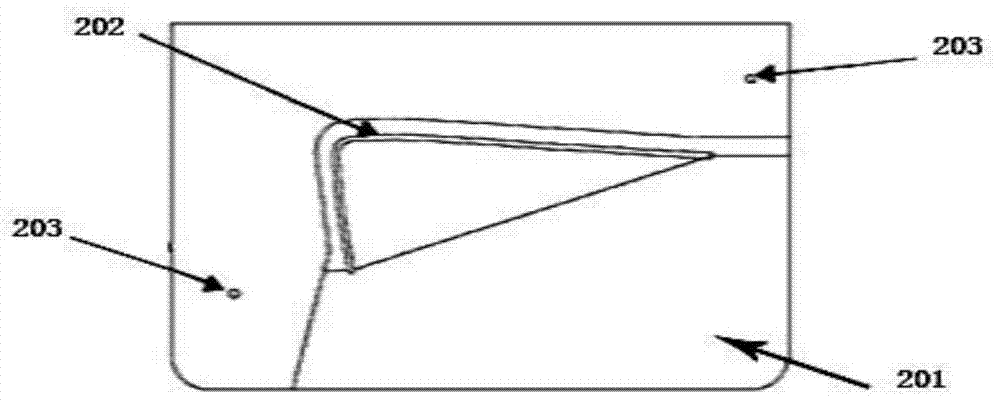

[0042] A collar lapel mold for hook clothing, such as figure 1 As shown, the collar lapel mold for hook clothes of the present invention is formed by laminating three-layer templates and then bonding one side. The bonding method adopts Gua box glue, or other bonding methods that allow the three-layer templates to be turned. The position corresponding to the three-layer template is according to the edge of the lapel to be processed, and the thread groove is opened for the required sewing part. Such as figure 2 As shown, the panel 101 opens a first round hole 102 at a position where the operation of the garment parts is not affected at 101, and an opening 103 is provided on the 101; as image 3 As shown, on the base plate 201, open a wire groove 202 according to the shape an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com