Novel laser rust removing device

A new type of laser derusting technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that the equipment cannot maintain the working posture, flash rust, weak adsorption force, etc., and achieve high commercial promotion and application value, The technical concept is advanced and practical, and the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

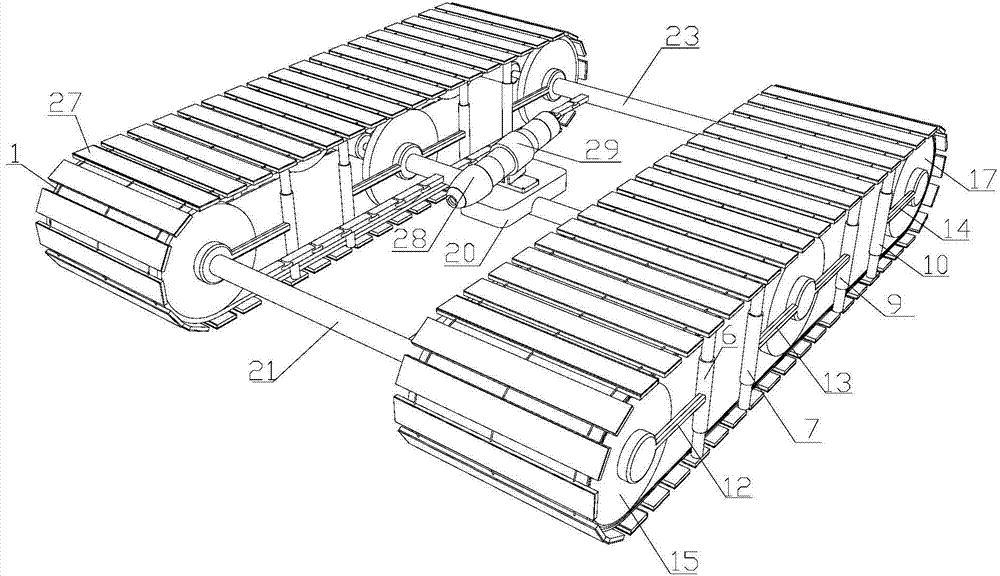

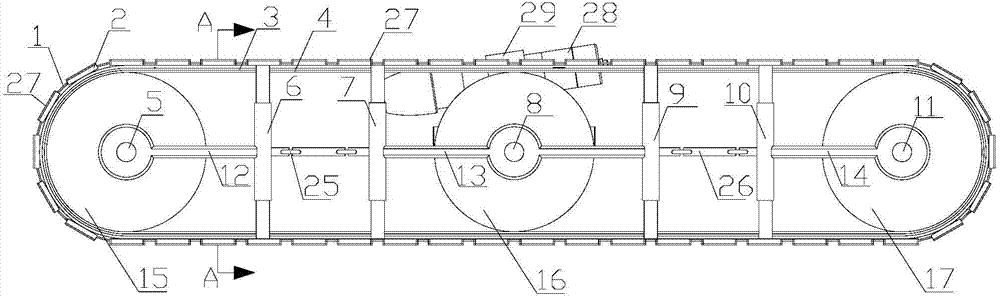

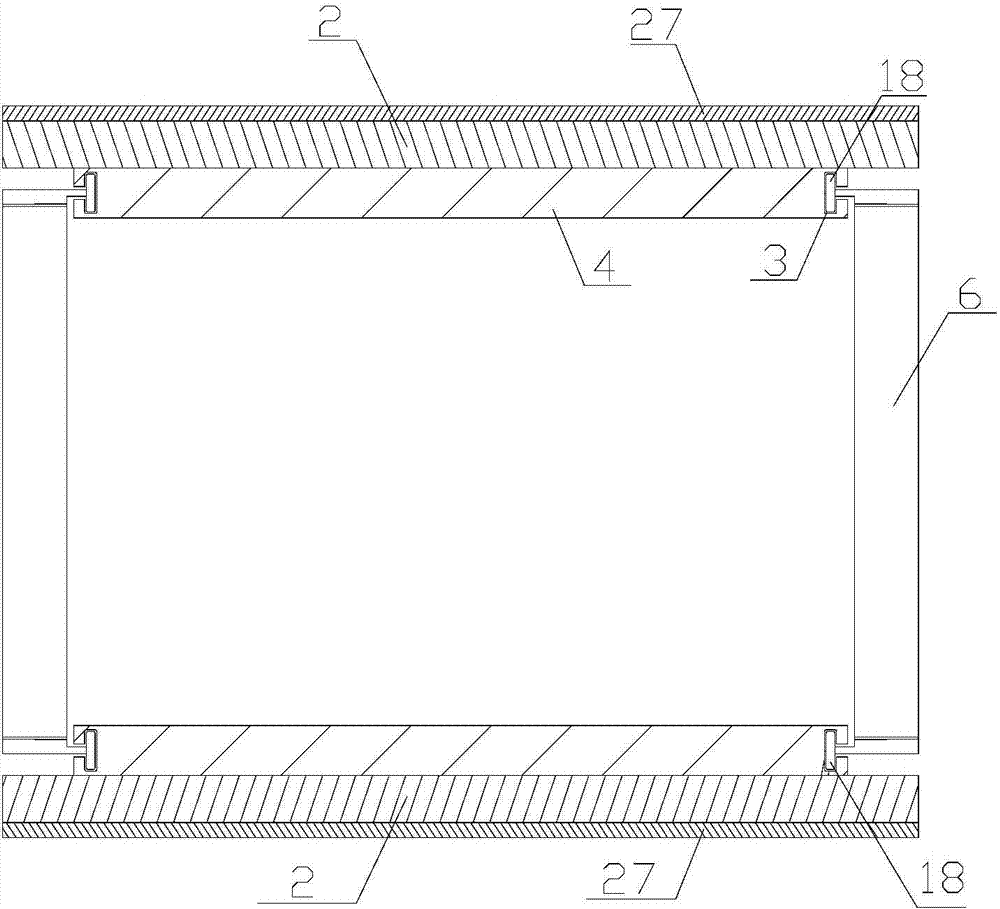

[0018] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

[0019] As shown in the figure, a new type of laser descaling device includes a laser descaling device 28 and a hull climbing wall mounting platform on which the laser descaling device 28 is placed. The hull climbing wall mounting platform includes two magnetic drive units , four sets of belt tension adjustment mechanisms, head beam 21, middle beam 22, tail beam 23, four flexible longitudinals 19 and an equipment carrying base 20, wherein the magnetic drive unit includes a head motor 5, a middle motor 8, a tail motor 11, The first driving wheel 15, the secondary driving wheel 16, the tail driving wheel 17, the track connecting hinge 1, the permanent magnet 2 and the transmission belt 4; Rod 7, middle and rear hydraulic telescopic link 9, tail hydraulic telescopic link 10, hydraulic telescopic link pulley 18, head hydraulic link bracket 12, middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com