A recirculating ball power steering machine spool, a screw assembly containing the spool, and a light hand steering machine

A power steering and recirculating ball technology, applied in fluid steering mechanism and other directions, can solve problems such as steering vibration, lower stiffness, large axial force, etc., achieve soft and smooth operation, reduce frictional resistance, and reduce contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

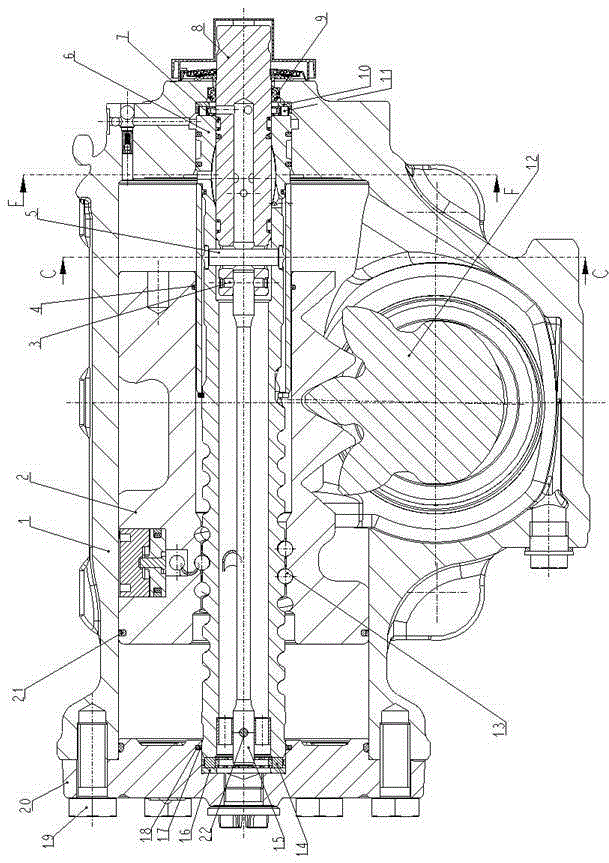

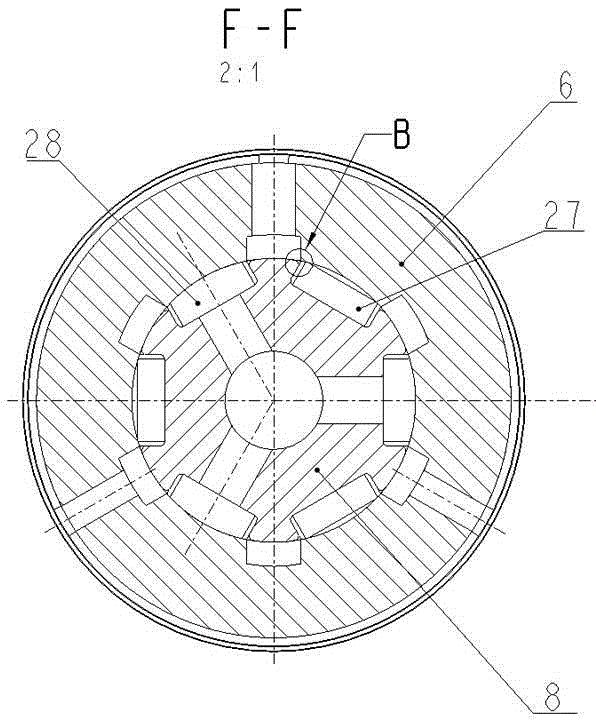

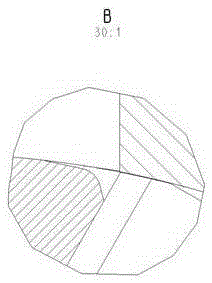

[0035] A recirculating ball power steering machine spool of the present invention, a screw assembly containing the spool and light hand power steering machine of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] as attached figure 1 , 2 , Shown in 3 and 8, light hand steering machine is mainly made of housing 1, housing cover 20, screw rod assembly, rack piston 2 and toothed fan shaft assembly.

[0037] The housing cover 20 is fixed to the opening end of the housing 1 by bolts, and the screw assembly, the rack piston 2 and the toothed fan shaft assembly are all arranged in the space formed by the housing 1 and the housing cover 20 .

[0038] The structures of the rack piston 2 and the toothed fan shaft assembly are identical to those of the rack piston and the toothed fan shaft assembly in the steering gear of the prior art. The rack piston 2 is arranged on the upper part of the housing 1 and is slidably fitted wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com