Press

A technology of presses and ceramic materials, applied in the field of presses, can solve problems such as delay, efficiency reduction, and press parts damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

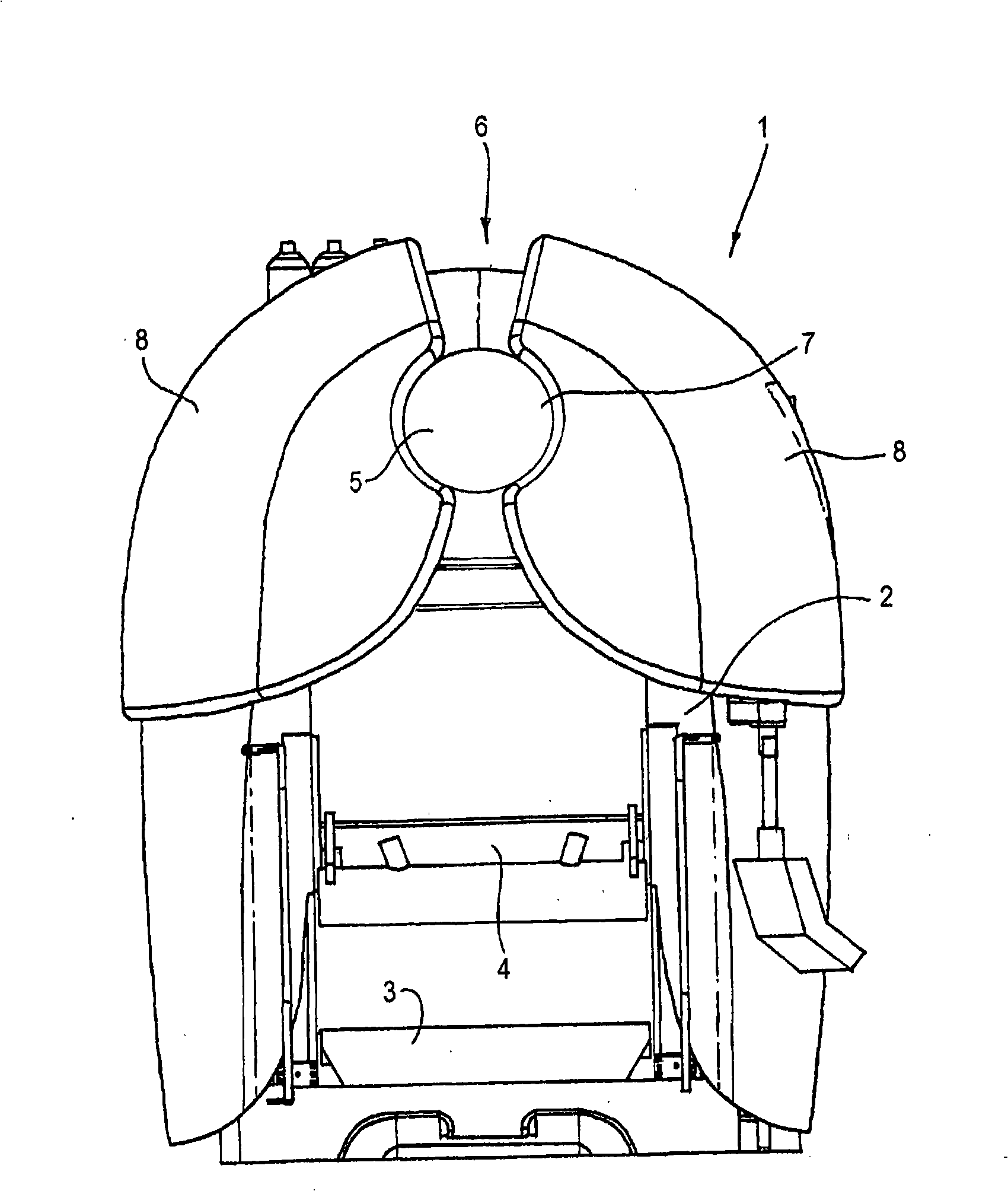

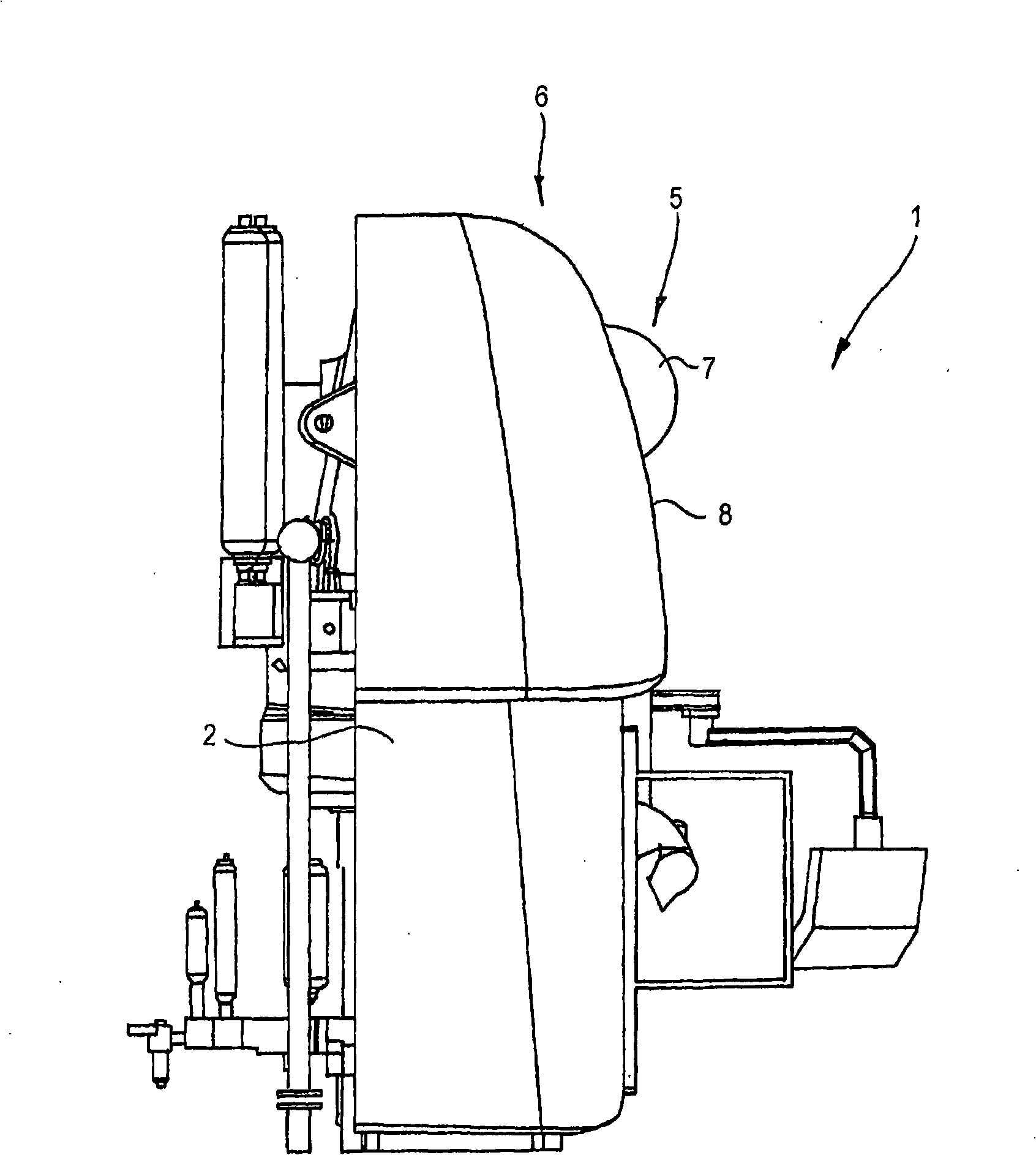

[0025] refer to figure 1 and figure 2 , shows a press 1 for pressing ceramic materials, which comprises a support structure 2 on which a base 3 is fixed.

[0026] Alternatively, the base 3 can be formed directly on the lower part of the support structure 2 .

[0027] The press 1 also comprises a movable beam 4 , which can slide towards and away from the base 3 relative to the support structure 2 .

[0028] The press 1 comprises drive means with hydraulic cylinders arranged to move a movable beam 4 .

[0029] A demoulding device can be associated with the base 3, on which is mounted a first mold half defining at least one mold cavity arranged to receive ceramic material.

[0030] The periphery of the at least one mold cavity is delimited by a frame, and the underside of the at least one mold cavity is delimited by a lower die punch driven by an ejector device and movable relative to the frame to discharge the ceramic material obtained by pressing ceramic tile.

[0031] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com