Energy saving control method of pneumatic ash conveying system in thermal power plant

A technology of pneumatic ash conveying and control methods, which is applied in the direction of conveyors, transportation and packaging, and conveying bulk materials, etc. It can solve the problems of large fluctuations in compressed air volume, frequent start and stop of air compressors, and unbalanced energy consumption. Achieve the effect of reducing quantity, reducing pressure wave drop and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

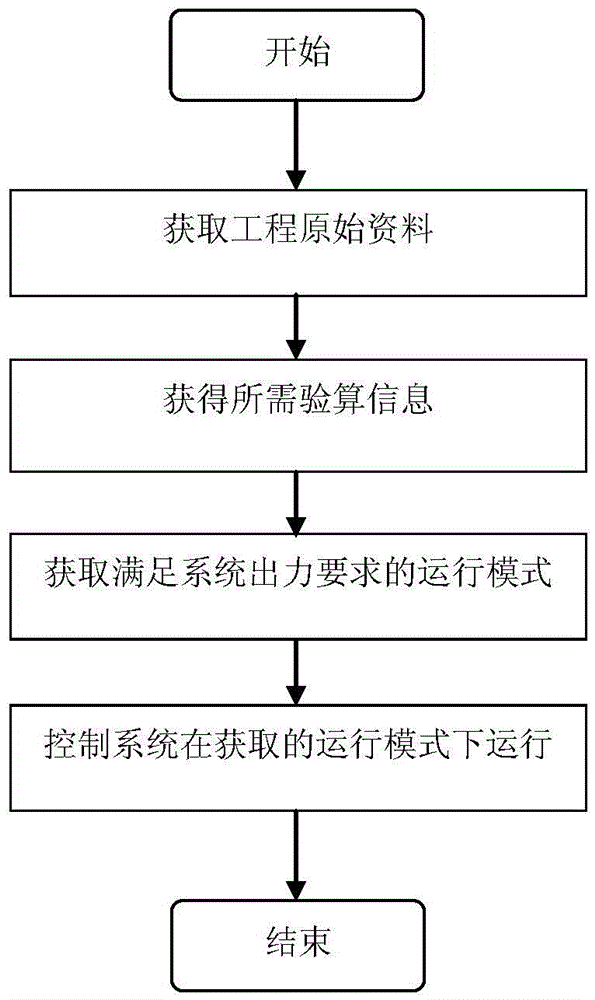

[0020] See figure 1 The main steps of the method proposed by the present invention include: obtaining the original engineering data, obtaining the information required for the verification calculation based on the original data, obtaining the operating mode that meets the system output requirements based on the information required for the verification calculation, and placing the system in the obtained operating mode run. These steps are described in further detail below.

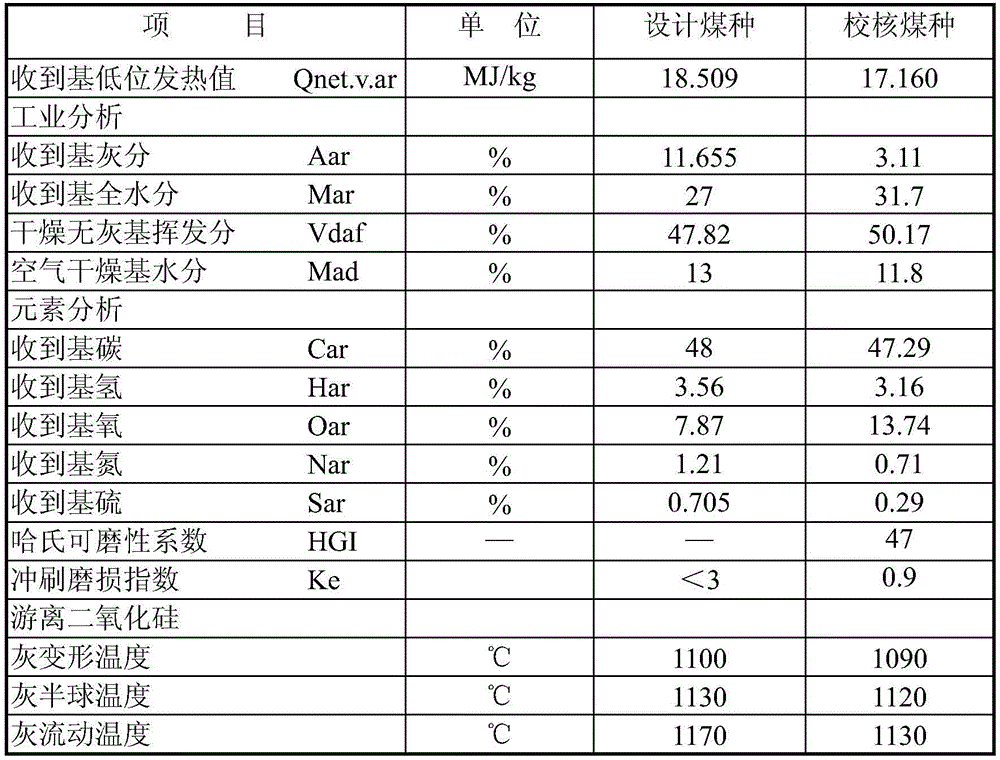

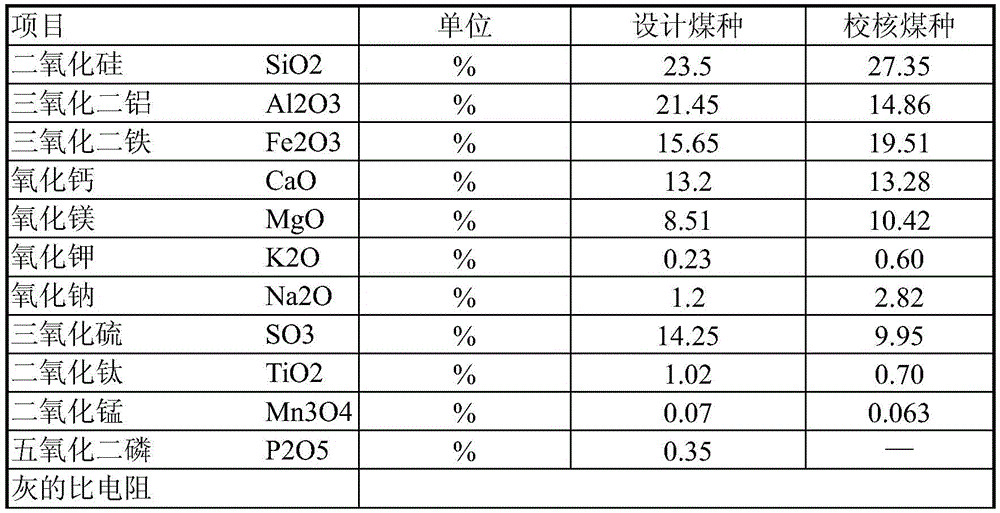

[0021] Obtain the original engineering materials of thermal power plants. The original data of the project include unit capacity, quantity, design and check coal quality data, the number and volume of dust hoppers, and the ash conveying system configuration of each dust collection area. The ash conveying system configuration of each dust collection area includes the ash discharge volume, the number and volume of silo pumps, the number and specifications of ash conveying pipelines, and the conveying length. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com